Home » Machine Vision

Articles Tagged with ''Machine Vision''

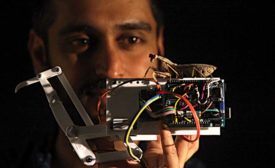

Deep Learning Machine Vision

In just a few short years, deep learning software has improved to the point that it can classify images better than any traditional algorithm—and may soon be able to always outperform human inspectors

May 6, 2019

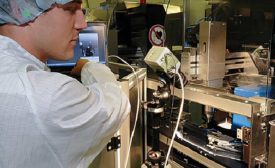

Maintaining Image Brightness in Vision Systems

A closed-loop approach is the best way to overcome variations in image brightness.

February 7, 2018

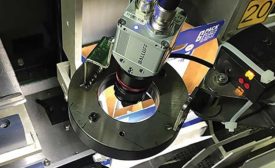

What’s New With Machine Vision Systems

New technology is making vision systems faster, more reliable and easier to use.

November 7, 2016

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing