Audi Pioneers ‘Virtually Controlled’ Production in EV Body Shop

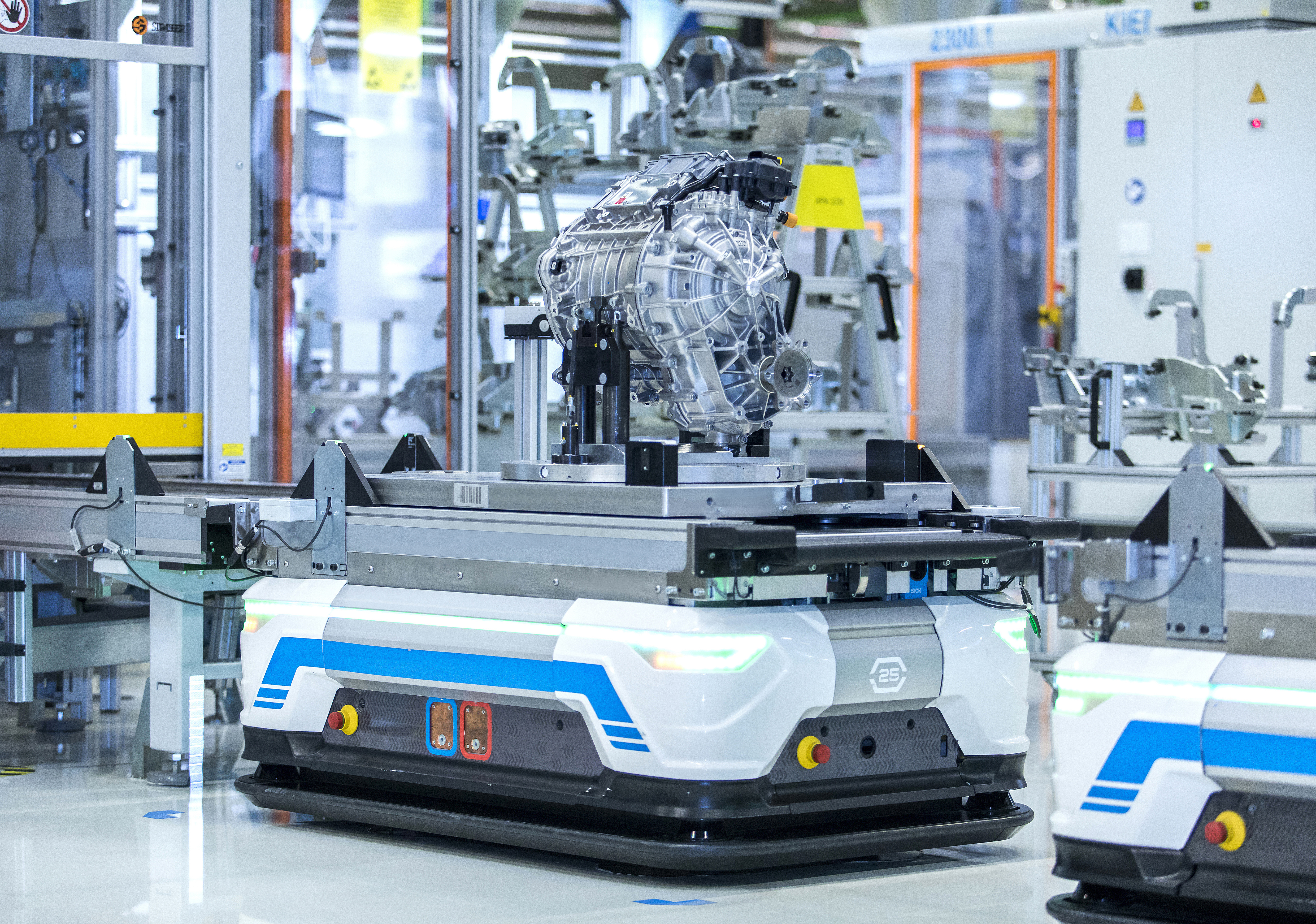

Photo courtesy Audi AG

BOLLINGER HOFE, Germany—Audi AG is using a virtual programmable logic controller in its assembly plant here that produces the e-tron GT sedan. The device supplied by Siemens operates on the Edge Cloud 4 Production (EC4P) platform in the body shop. It replaces traditional hardware-based PLCs.

The virtual programmable logic controllers enable the rapid introduction of software and new functions that can be updated and managed centrally. With the EC4P, the efficiency and speed of production processes can be significantly increased.

“The use of virtual programmable logic controllers in the body shop is an important productivity leap in our 360factory strategy for efficient and data-driven manufacturing,” says Gerd Walker, board member for production at Audi AG. “We want to bring the local cloud for production to all plants and leverage advances in digital control systems in the process.

“Once again, the Böllinger Höfe facility serves as a real-world laboratory for digital technologies,” notes Walker. “With the new TÜV-certified virtual control system from Siemens, [we are] laying the foundation for flexible and data-driven production. [We] can control and monitor production in real time, regardless of location.”

"Controllers are the 'brains' of machines and factories,” adds Cedrik Neike, CEO of digital industries and member of the managing board at Siemens AG. “Now, we are virtualizing these brains and bringing them to the cloud.

“This accelerates the digital transformation at Audi and increases agility, efficiency and security in production for more flexible, future-proof manufacturing,” claims Neike. “Together, we are taking automotive production to a new level and significantly strengthening competitiveness.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!