Automotive Industry

New Software Simulates the Body-in-White Assembly Process

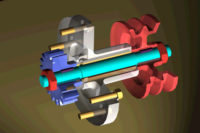

Software saves time and money when setting up welding and hemming processes in a body-in-white assembly line.

PFÄFFIKON, Switzerland—AutoForm Engineering GmbH, a supplier of software for stamping and body-in-white (BiW) assembly processes, has released a new version of its AutoForm Assembly R12 software. This version offers new capabilities and enhancements for the BiW assembly process chain, in particular for hemming, process engineering, and process optimization and evaluation.

AutoForm Assembly R12 offers advancements and new options for assembly process engineering. During this stage, engineers have to import assembly CAD data, which often includes a large amount of information that is not needed in its entirety for defining the assembly process. AutoForm Assembly R12 allows engineers to filter CAD data specifically for defining the assembly process. They can then easily select elements to import which, once imported, maintain the same CAD structure and original element names.

In addition, AutoForm Assembly R12 significantly improves the behavior of the thermal model, which was developed to enable the prediction of thermally induced distortions that occur during welding processes. Line welds now consider the time-dependent thermal behavior of the process, enabling more realistic welding simulations. This allows engineers to optimize welding processes already in the process engineering stage.

The software also offers new capabilities that are important for assembly process optimization and evaluation. In practice, assembly equipment is continually adjusted to resolve dimensional deviations and their effects on production. With AutoForm Assembly R12, process adjustments can be made virtually, enabling engineers to define which clamps should be considered for shimming and which joins should be considered for teaching. Selected clamp positions can be moved within the defined range, and nearby joins can be taught as needed based on sheet movement. By running multiple simulations, the software enables users to determine the optimal parameters that can be applied to resolve accuracy issues in assembly. When a solution is found, the settings can be easily mirrored in the physical process, eliminating the costly traditional trial-and-error approach.

AutoForm Assembly R12 brings new options for the hemming operation. Parts that have several disconnected flanges can now be hemmed with a single tool. The software enables a more realistic process definition, a reduction in the number of hemming tools, and a shorter amount of time for the simulation setup.

“The software allows for an even more reliable digital process representation, which serves as a blueprint for the physical process in BiW assembly production,” says Markus Thomma, Ph.D., chief marketing officer of the AutoForm Group. “The digital process model enables users to determine which adjustments need to be made to the physical process. With AutoForm Assembly R12, users can significantly reduce the number of physical tryout and quality loops, which results in lead time and cost savings.”

For more information, click www.autoform.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!