Wire Processing Products

Cut, Strip and Crimp System Has Programmable Z-Axis

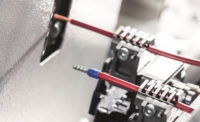

Image courtesy of Komax Group.

The Alpha 520 automatically cuts, strips and crimps wire and cable. Its fully programmable Z-axis optimizes the crimping process by automatically adjusting the vertical height of the crimping module. This reduces changeover times. The machine stores the optimal position of the crimping module for each article, which eliminates the need for manual adjustments.

For open barrel “F-style crimp” terminals, the Z-axis positions the crimping unit below the wire line, allowing the wire to swing over the crimping ears of the terminal. During the process, the wire is lowered into the terminal in conjunction with the crimping tool, ensuring accurate wrapping of the terminal ears around the conductor to form the crimp.

For closed barrel applications, the wire must be inserted into the terminal’s cavity before crimping. In this case, the Z-axis automatically raises the crimping module, ensuring the correct insertion of the wire into the terminal. For wires less than 22 AWG, the Z-axis improves the quality of crimping by raising the crimping module and reducing the vertical movement of the wire as it is lowered into the F-style crimp. By reducing the wire movement, the crimping process is more stable.

Komax Group

www.komaxgroup.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!