Robotics

Low-Cost Robotics for Adhesive Dispensing

A new automation marketplace enables engineers to quickly design and procure turnkey systems to automate dispensing and other assembly processes.

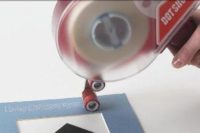

Using robots to dispense adhesives can enhance efficiency, precision and safety. Automating this monotonous and non-ergonomic task minimizes material waste and protects personnel from contact with chemicals.

However, automating the dispensing process comes with some challenges. One is the need for flexibility. Conventional dispensing robots rarely meet this need without substantial cost. In fact, dispensing robots can be prohibitively expensive, easily costing more than $100,000. This puts the technology beyond the reach of small and midsized manufacturers.

Fortunately, there are now low-cost automation options for industrial tasks—including dispensing. These robotic systems are available through an online platform that aggregates components from various industrial suppliers, enabling engineers to design, build and buy a robotic system that meets their application and budget requirements. These systems are significantly less expensive than conventional robots. In addition, the platform provides consultation, testing, integration and other services.

About igus RBTX

The igus RBTX marketplace is designed to make automation more accessible to a broader range of manufacturing operations. Through its cost-effective offerings, user-friendly platform and support services, RBTX lowers the barriers to entry for automation and empowers manufacturers to enhance their operational efficiencies and competitiveness.

The marketplace includes robots, grippers, control systems, vision systems, pneumatics, and safety systems. Besides igus, numerous suppliers are represented, including ABB, Epson, Universal Robots, Schunk, OnRobot, Schmalz, Loctite, Kolver, Weber, Sick, Inspekto and Turck.

For dispensing, RBTX systems can take many forms that vary in cost and complexity. For example, one option is a multiaxis robotic arm. A second, slightly more complex option is to deploy an XYZ gantry system, which combines several linear axes. A third option is to implement an entire robotic cell consisting of the robot, control system, switch cabinet, safety technology and other components.

For these and other dispensing systems, components are available starting at $9,647, reducing costs by as much as 90 percent compared with standard automation systems. These systems are not only cheaper up front, but they are also less expensive to operate. They are equipped with self-lubricating materials that reduce or even eliminate routine maintenance, which minimizes long-term costs.

Beyond configurable, out-of-the-box robotic systems, the RBTX platform offers “RBTXpert service,” which provides engineers with remote integration support. This service includes video consultations and live testing of applications, ensuring that the systems are feasible and effective before purchase.

RBTX Systems for Dispensing

Here are a few examples of what’s possible with RBTX systems:

- Automotive air filter assembly. This process involves sealing the frame of the filter, maintaining the fold of the filter paper, and then bonding the frame to the filter paper. These tasks require precise application of adhesive over small areas. RBTX robots surpass the capabilities of human workers, providing a significant boost in consistency and quality.

- Electronics assembly. RBTX gantry robots can precisely dispense adhesive on circuit boards. This system offers three degrees of freedom, allowing movement in any position and providing high levels of accuracy.

- Furniture assembly. The robolink DP 5, a five-axis robot, is used for tasks such as case bonding. It can be mounted on a drylin seventh axis for extended reach.

One notable application of RBTX robots involves Volkswagen. At one of the company’s assembly plants in Germany, these robots dispense adhesive for rear battery consoles. Automating this process has streamlined operations and enhanced quality.

An igus robolink six-axis robot applies two beads of adhesive to the rear battery console. Previously, employees had to manually remove the consoles from containers, position them on a table and apply two beads of acoustic adhesive. They then had to install the consoles in the side trunk area of the vehicles. The process was time-consuming, stressful and error-prone.

The robolink system—which costs less than $10,000—overcame these challenges, automatically removing the consoles from a parts station and dispensing the adhesive. This freed up employees’ time and improved the quality of the application.

A flexible, compact robot, the robolink system moves in six degrees of freedom and can be equipped with or without a control system. It is ideal for applications with precision requirements of ±2 millimeters, loads up to 0.5 kilogram, and cycle times greater than 7 seconds.

Advantages of RBTX Systems

Adopting RBTX robotic systems for dispensing applications offers several benefits, including:

- Precision and consistency. A primary advantage of RBTX robotic systems is their high level of precision and consistency.

- Cost-effectiveness. RBTX robots provide a cost-effective pathway to automation. The marketplace model lets engineers select from a range of products that fit their budget and technical requirements, making advanced technology accessible without substantial upfront investment.

- Safety and productivity. Automating dispensing reduces the need for workers to handle potentially hazardous materials and perform repetitive tasks.

- Flexibility. The modular nature of RBTX systems means that they can be easily adapted and reconfigured for different tasks. This is a big advantage for manufacturers that must respond quickly to changes in production requirements or product designs.

- Ease of programming. Engineers can easily program the RBTX robots using free control software that doesn’t require programming knowledge. This software facilitates parameter changes and enables engineers to upload DXF files for programming.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!