Automated Assembly Systems

JOT Introduces Modular Automated Microfactory Concept

The concept is intended to make automated assembly lines more flexible and faster and less expensive to implement.

OULU, Finland—JOT Automation Inc. and EID Robotics have introduced a system of standardized, modular, robotic cells that can be combined to create microfactories for localized automated manufacturing of products.

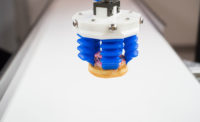

The concept, called ANT Plant, is intended to make automated assembly lines more flexible and faster and less expensive to implement. Each cell typically contains one process or application, and the cells are integrated through standard, pre-tested and verified interfaces end-to-end. This enables manufacturers to customize the line configuration and capacity specifically to their needs. Preconfigured cells are available for a variety of processes, including assembly, testing, dispensing, soldering, staking, screwdriving, ultrasonic welding, labeling, laser marking and packaging.

Because the cells are standardized, delivery time for a microfactory can be up to 30 percent faster than traditional automation systems. In addition, installation of a complete microfactory can be done in only eight hours, since the cells can be combined simply by connecting power lines and the communications network.

All production applications in the microfactory have their own I/O modules and are connected with a fieldbus, so they are easy to change. Robots are mounted to the ceiling of the cell, which maximizes the work area. Application and control software is also modularized to each function and application.

The microfactory line is controlled from a graphical user interface (GUI). The GUI has different user access levels, which are defined by the customer. An operator can run the line and monitor the cell states, yield and output. Any changes to settings can be done by an advanced user. Production engineers can also easily change settings and make service and maintenance actions when needed. A six-module ANT Plant can be operated by just one person during a shift.

Engineers can support a line remotely and make changes with minimum downtime to the operation. For uninterrupted operation, data is continuously collected from the product line and analyzed in the cloud. In case of any deviations in the process, problems can be fixed remotely before they stop the production line.

The ANT Plant is designed to manufacture products that weigh less than 10 kilograms and have several assembly process steps. The concept is already being used to assemble LED light fixtures, medical devices, and batteries for electric vehicles.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!