Alone among plastic joining technologies, laser welding offers a range of benefits, such as gentle and vibration-free joining; particle-free assembly; the ability to weld precision fluid paths; strong bonds with hermetic seals: exceptional aesthetics; and the versatility to bond a wide range of polymers.

Some of the most advanced laser-welding applications involve extremely small plastic components. In automotive and personal electronics, creating compact devices that contain sensors and other tiny, delicate internal elements is a high priority. The same is true in the medical field, where precision joining of small plastic components is essential for devices used for in-vitro diagnostics (IVD), vital-signs monitoring, and injection- and inhalation-therapy applications. Here, the precision and controllability of micro laser welding are ideal for creating microfluidic pathways as short as tenths of a millimeter long and as narrow as 100 microns wide. These pathways are often found in parts with a total surface area smaller than a postage stamp.

On the opposite end of the spectrum, laser welding is also used for joining larger plastic assemblies, including appliances, automotive lamp and lighting assemblies, fluid control valves, sensor and control bodies, switches, and pump and impeller assemblies. In applications like these, the ability to precisely control heat inputs, combined with the ability to join a diverse range of polymers, make laser welding preferable to more costly, labor-intensive assembly methods involving adhesives or fasteners.

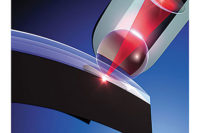

Laser welding transmits focused laser energy through a transmissive part to an absorptive part, heating the joint interface, so that gentle compressive force can complete the weld. Illustration courtesy Emerson

Quasi-simultaneous laser welding uses movable mirrors to focus laser energy along the contours of the joint in a continuous, closed loop. The ability to follow varied product contours when welding makes quasi-simultaneous laser welding a preferred option for high-mix, low-volume production. Illustration courtesy Emerson

Basics of Laser Welding

Laser welding can be performed in two ways. By understanding the nature of the process itself, and then the benefits of each method, engineers can better determine how to use laser welding to meet their unique assembly needs.

In laser plastic welding, laser light is beamed through a “transmissive,” or transparent, part to the surface of an “absorptive,” or dark, part. The laser energy generates heat at the interface between the two parts that melts the plastic. Then, with the help of controlled compressive force, the softened part surfaces are brought together and the weld is completed in a matter of seconds.

Laser welding can join clear-on-clear parts with exceptional aesthetic and functional results. Photo courtesy Emerson

A variety of application-specific variables affect the absorption and transmission of laser energy, and therefore the rate at which welds can be made. These variables include the optical properties of different plastics (e.g., different levels of transmissibility), different part thicknesses, and the laser wavelength that is used. Generally, however, the “sweet spot” for laser welding is in the infrared light range, somewhere between 900 and 1,100 nanometers. A recent advance in laser welding makes it possible to weld two transmissive parts, provided that a biocompatible, photosensitive material is applied to one of the parts. This advance makes it possible to assemble clean, particle-free, fully transparent devices, which are often preferred for medical and IVD applications.

| Application Requirements | Simultaneous Laser | Quasi-Simultaneous Laser |

|---|---|---|

| Production Volume, Mix | High volume, low mix | Low volume, high mix |

| Tooling | More complex, part-specific waveguides | Simple fixturing |

| Part Geometry | 2D or 3D, simple to complex | Flat, 2D, simple 3D |

| Cycle Time | Minimal, typically 1 second or less | Several seconds |

| Job Changeover time | Fast, with replaceable waveguides | Quick, using preprogrammed production recipes |

One Technology, Two Methods

There are two methods of laser plastic welding: simultaneous and quasi-simultaneous.

Simultaneous laser plastic welding (technically known as simultaneous through-transmission infrared or STTIr) is a widely accepted method for high-volume production of plastic assemblies ranging from micro parts to large parts. This method delivers laser energy to the weld zone between two parts using specially designed waveguides. Waveguides are fiber optic bundles that are custom-shaped to heat all of the contours of the weld joint simultaneously. Then, the mating parts are compressed together to complete the welds. The use of custom waveguides enables rapid, reliable welding, even when parts have complex, 3D geometries. So, STTIr is the preferred method for high-volume production in any business where clean, particle-free and hermetically sealed parts are essential.

STTIr laser welding relies on fiber optic bundles, called waveguides, that are specific to the contours of each part. These heat all part surfaces simultaneously to enable fast, high-volume welding. Illustration courtesy Emerson

But simultaneous laser welding is not ideal for every application. High-mix, low-volume manufacturers often prefer a different laser welding method: quasi-simultaneous laser welding, which is also known as “laser-trace” or “galvo” welding. Instead of relying on part-specific waveguides, this process utilizes a laser and a set of movable mirrors, positioned over a tabletop where welding takes place. In operation, the movable mirrors, steered by servo-driven galvanometers, focus a beam of laser energy along the contours of weld joint in a continuous, closed loop. The heating effect on the plastic is rapid, but not simultaneous, hence the name “quasi-simultaneous.” The heated parts are then compressed, completing the weld. Part for part, quasi-simultaneous weld cycle times are longer, though total cycle time can still be measured in seconds.

Quasi-simultaneous laser welding platforms, like the new Branson GL-300 from Emerson, offer high power (300 watts maximum) and advanced features to weld everything from micro-sized medical products to larger automotive components. Photo courtesy Emerson

The quasi-simultaneous process offers manufacturers the flexibility of using a programmable laser-welding platform to weld a full array of 2D parts, simple 3D parts, and larger part assemblies without the need for dedicated, part-specific waveguides. Weld platforms offer the versatility to perform everything from micro-sized welds for electronic or medical devices to small welds suited to industrial or automotive products. The sole limitation of this process is the maximum size of the part (up to 300 millimeters) and the ability of the laser-aiming mirrors to access all essential contours of the weld area.

No matter which method engineers choose, a number of global vendors offer laser plastic welding technology and platforms to meet any need. From tabletop to production floor, the latest laser-welding platforms offer multiple weld modes, easy-to-use controls, sophisticated data capture capabilities, and data communication options that make it easy to transfer equipment status and weld data from weld equipment to manufacturing execution systems.

ASSEMBLY ONLINE

For more information on plastic welding, read these articles:

Optimizing Ultrasonic Plastic Welds

New Process Welds Clear Plastic Parts

Adhesive Bonding vs. Ultrasonic Welding for Assembly of Medical Devices