A Roundup of New Robots

May 1, 2024

A Roundup of New Robots

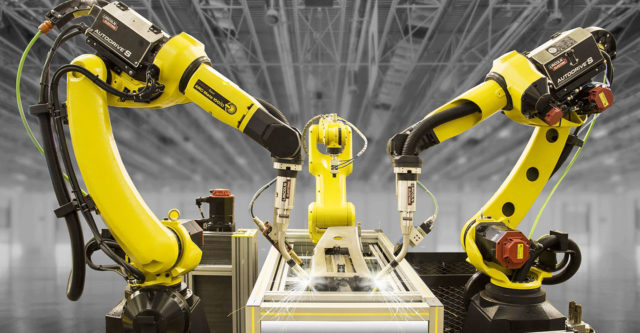

May 1, 2024Manufacturers are deploying robots at a record pace. Advances in motion control, vision guidance, artificial intelligence and collaborative technology are making robots easier to implement than ever. Here’s a look at some of the latest in robotic technology.

Photo courtesy FANUC America Corp.

Manufacturers are deploying robots at a record pace. Advances in motion control, vision guidance, artificial intelligence and collaborative technology are making robots easier to implement than ever.

The numbers speaker for themselves. Worldwide sales of industrial robots are expected to grow at a cumulative annual rate of nearly 12 percent over the next six years, exceeding $123.8 billion by 2030, according to a new report by consulting firm Vantage Market Research.

Here’s a look at some of the latest in robotic technology.

Robot Has Fully Enclosed Design

The M-710iD/50M six-axis robot can carry a 50-kilogram payload and has a curved J2 arm, which minimizes interference with workpieces and fixtures. Fully enclosed with an optional IP67 rating, the robot’s reducers are well-protected, and it’s resistant to wet, dusty or dirty tasks. It has a maximum reach of 2,606 millimeters. Applications include assembly, arc welding, spot welding, palletizing, material handling, material removal and dispensing.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

FANUC America Corp.

www.fanucamerica.com

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

Suction Cups for Sheet Metal Handling

CTC bell-type suction cups hold fast to sheet metal. Their bell-shaped design combines the advantages of both flat and bellows suction cups. They have the strength and anti-slip qualities of the former, with the added abilities of the latter to grip complex or angular shapes. The cups have a large deflection capability, adapting easily to gripping flat, convex or angular sheet metal. Their anti-slip cleats make it easy to move heavy, oily sheets quickly and efficiently, while their central stops ensure that thin sheets are gripped tightly without deforming them.

The cups are available in four diameters, from 40 to 100 millimeters, and three mounting configurations (3/8G male or female and 32 millimeter square). All are made from thermoplastic polyurethane for excellent resistance to wear and oil.

See this company at The ASSEMBLY Show Oct. 22-24 in Rosemont, IL.

Coval Vacuum Technology Inc.

www.coval-inc.com

SCARA With High-Force Z Axis

The IRB 930 SCARA robot is available in three variants capable of handling 12- and 22-kilogram payloads. Engineered for fast point-to-point tasks that demand high payloads and large work areas, the robot’s Z axis provides up to 250 newtons of downward force, a 200 percent increase from the previous model. This makes the robot ideal for force-intensive operations, such as screwdriving and assembly.

ABB’s OmniCore controller powers the robot. The controller offers best-in-class motion control through TrueMove and QuickMove, alongside built-in digital connectivity and scalable functions. The controller delivers a cycle time of 0.38 second, with a positional repeatability of 0.01 millimeter.

ABB Robotics

new.abb.com/products/robotics

Dispensing Robot

Manufactured in the U.S., the RPX robotic dispensing machine boasts machine-tool quality construction and accuracy. It is available with an integrated parts transfer system that can be used to automatically load and unload parts for unattended operation. The embedded control system supports multiple vision systems, six axes of servo control, and expandable I/O.

Dispense Works Inc.

www.dispenseworks.com

System for Programming Robots

The TwinBox system consists of robot programming software pre-installed on an industrial PC or a small single-board computer. This self-contained system can manage multiple devices and robots from various manufacturers simultaneously in a production environment. The system offers a full suite of features that enable engineers to easily set up and manage robotic systems.

TwinBox can be easily controlled through a web browser, allowing engineers to trigger actions remotely and have a 3D view of their cells.

The system can be installed either next to or within a factory robot’s control system. A key feature is its ability to function effectively without the need for a mouse, keyboard and monitor. It solely requires network interfaces to seamlessly connect to an internal network and a robot control system. This allows users to save more of their valuable floor space while still being able to use all the features in the software.

The system supports multiple operating systems and hardware architectures, including Windows and Linux Debian or Ubuntu running on Intel x86-64 platforms or ARM. RoboDK also provides dedicated builds for systems such as the Nvidia Jetson or Raspberry Pi-based industrial computers.

With its remote interface, engineers can access TwinBox from anywhere in the world, with full control of all connected robots, devices and sensors. This allows engineers to monitor robots remotely, in real-time, giving them more flexibility and control over their automation.

Engineers can connect multiple robots from different manufacturers together into one cohesive system. This increases flexibility and speeds up the integration process. RoboDK supports more than 1,000 robot models from more than 50 brands. It also interfaces with sensors and vision systems.

RoboDK

robodk.com

Teach Pendant Programs Robots

The R86TB teach pendant can handle a series of processes from setup to maintenance, obviating the need for an on-site computer. It has a 10.1-inch high-definition display so that any function can be easily visible and accessed from the customizable home screen or page list. Major functions of Melsoft RT ToolBox 3, Mitsubishi’s PC-based robot programming software, are accessible and equipped to provide program support functions, parameter and program screens, and 3D monitoring.

Additional features of the teach pendant include data analysis and real-time monitoring for troubleshooting; secure hardware buttons for tactile and consistent operation; improved processing speeds; and security functions. Compatible with the CR800 and CR700 controllers, the teach pendant gives engineers increased visibility and operability to ensure smooth operations and high performance.

Mitsubishi Electric Automation Inc.

us.mitsubishielectric.com

Heavy-Duty Robot With Long Reach

The KR FORTEC six-axis robot can handle loads ranging from 240 to 500 kilograms. Maximum reach ranges from 2,800 to 3,750 millimeters. The hollow shaft ensures simple and safe integration of the customer-specific energy supply system. The two in-line wrists are waterproof and dustproof as standard equipment. The robot can operate at temperatures of 0 to 55 C. Several foundry variants are available for harsh and dirty environments.

This energy-efficient, durable robot provides a mean time between failures of up to 400,000 hours. Optimized accessibility facilitates maintenance. The robot’s modular design simplifies maintenance: The same spare parts are used for three robot families: KR Fortec, KR Quantec and KR Fortec Ultra.

The working envelope of the robot can be expanded with the KL 4000 linear motion unit, which can be built in lengths of 1.5 to 30 meters.

Kuka

www.kuka.com

Autonomous Mobile Robot

With an easy-to-use interface and open architecture, the Lexx500 autonomous mobile robot is scalable and interoperable. Factories can employ one robot or a fleet of units working together safely and flexibly alongside people and existing automated systems. The robot can transport irregular cargo and payloads of up to 500 kilograms. The robot’s safety system combines LiDAR sensors, ultrasonic sensors and depth cameras so it can operate safely and collaboratively with people.

LexxPluss Inc.

lexxpluss.com

Mobile Manipulator

The RB-Kairos+ is a mobile manipulator equipped with a cobot from Universal Robots. The manipulator can be used for various applications, including pick and place, part feeding, metrology, quality control, packaging, cleaning, polishing, screwdriving and drilling. A UR+ certified product, the robot can navigate autonomously and can be configured with various sensors and components found within the UR+ ecosystem. With optional safety laser scanners, the robot can safely share a workspace with people. Omnidirectional kinematics are provided by four high-power drive wheels. It can carry up to 250 kilograms and move at a top speed of 1.5 meters per second. It can operate autonomously for up to 12 hours.

Robotnik Automation

robotnik.eu

Six-Axis Robot for Sterile Conditions

The TX2-40 Stericlean+ six-axis robot is safe for use in ISO Class 5 clean rooms. The robot is specifically designed to perform highly aseptic tasks in isolators. Its hygienic design features include an FDA-compliant surface coating and joint seals. It is VHP/H2O2 compatible for higher cleanability and chemical resistance. It has a maximum reach of 515 millimeters and can carry a payload of 2 kilograms. Positional repeatability of ±0.02 millimeter.

Stäubli International

www.staubli.com

ASSEMBLY ONLINE

For more information on robotics, read these articles:

AI-Enhanced Robots Improve Aircraft Production

Manufacturers Test Humanoid Robots in Factories

Robots Automate Assembly of Battery Packs for Electric Buses

.jpg?height=300&t=1743848480&width=300)