Based in Plymouth, MI, Adient plc is the world’s largest manufacturer of automotive seating, accounting for one-third of the global market and providing components for 25 million vehicles.

Adient was founded as a spin-off from Johnson Controls in 2016. Today, the company works with all major automakers and vehicle classes, and it operates some 200 assembly plants in 30 countries.

One of those factories is a 125,000-square-foot plant in West Point, GA, where seats, door panels and other interior parts are assembled for the Kia Sorento. At the West Point factory—like all Adient facilities—things can change at a moment’s notice. “Customers are always reconfiguring and adding new products and updating standards. To keep up and stay competitive, our plants must be flexible and efficient,” says Todd Emmons, an engineer in the automotive business unit for Adient.

Indeed, flexibility and efficiency were top of mind when Adient, then part of Johnson Controls, began building the plant in 2009. Engineers set out to design a state-of-the-art assembly plant that could accommodate the ever-evolving demands of the automotive industry.

“Our plan was to equip the plant with the most reliable, functional, cost-effective and reusable technology possible,” says Emmons. “Flow Cell workstations from UNEX Manufacturing helped us deliver on that plan.”

Gearing Up For The Future

At the plant, employees assemble seats, door panels and other interior parts for the new Kia Sorento. Subassemblies for some 500 cars a day move through the facility. “This is a high-volume plant. We’re completing 55 jobs an hour, and the goal is to step that up to 60 jobs an hour,” says Emmons. “Every minute counts, and every inch of workspace does too.”

In designing the plant, Emmons worked with John Maicki, president of DR Storage Systems, to identify the line-side assembly technology that would best fit current and future production needs. “The Adient team had very specific requirements. They wanted something durable, ergonomically sound and capable of accommodating the various product sizes on the production line,” says Maicki. “Most important, they needed an assembly line product that could be moved, adjusted and reused as production demands changed.”

In the past, tubular pipe structures had been used on assembly lines in some plants, but Emmons and Maicki agreed they would not be effective for the Georgia plant. “Tube and joint structures are highly customized and difficult to move from station to station. So, if the materials change on the assembly line, you have to order completely new racks and install them. This takes time and money,” says Maicki.

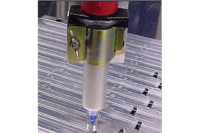

A better alternative came from UNEX. “We did a thorough analysis of the line-side racks available, got quotes from several vendors and had prototypes developed. Our decision was based on what was best in terms of reliability, cost-effectiveness, functionality and reusability. Flow Cell was the obvious choice,” says Emmons.

Efficiency Takes A Front Seat

The Flow Cell units offer many benefits for the plant, including:

Efficient use of space. “We only have 84 inches of pick space per workstation,” says Emmons. “The Flow Cells are built in such a way that we never waste an inch of space. And UNEX’s Flow Bed carton flow accommodates a variety a variety of materials, whether we are working with seats, door handles, power controls, air bags and the many different types of brackets and buttons. ”

Uninterrupted work flow. “Our Georgia plant is a just-in-time operation,” explains Emmons. “We have to keep things moving without interruption, so that we can deliver product exactly when the nearby Kia facility is ready for it. The Flow Cells are configured in such a way that productivity remains high. And if we need to reconfigure the carton flow beds, it’s simple to do. In fact, reconfiguring the Flow Cells is three times faster than reconfiguring other types of products.”

Reusability. “This is the biggest benefit,” notes Emmons. “Soon, we’ll be adding new car parts to the line for other types of vehicles. We can simply pick up the Flow Cells, move them to another place in the plant or another new location entirely, and reconfigure them. There’s no need to buy new racks.”

Added value. “The more efficient we can make the process, the more value we can offer customers, and that translates into more products for our operations,” says Emmons.

Both Emmons and Maicki have a long history with UNEX. “We’ve used other UNEX products in our plants, and UNEX was the clear choice for the Georgia facility,” says Emmons. “Overall, we’ve ordered 41 Flow Cells and used the UNEX instructions to assemble them in less than a half an hour each.”

Maicki adds, “I first recommended Flow Cell to a customer in 2003, and I’ve been recommending it ever since. The Flow Cells have broad application and always provide the quality and durability customers need on the line. It’s always a success story with UNEX.”

For more information, click www.unex.com.