Gap-and-Flush Inspection Brings Door-and-Fender Perfection

Stellantis N.V. makes the Chrysler 300, Dodge Challenger and Dodge Charger at its Brampton Assembly Plant in Ontario, Canada. Photo courtesy Stellantis N.V.

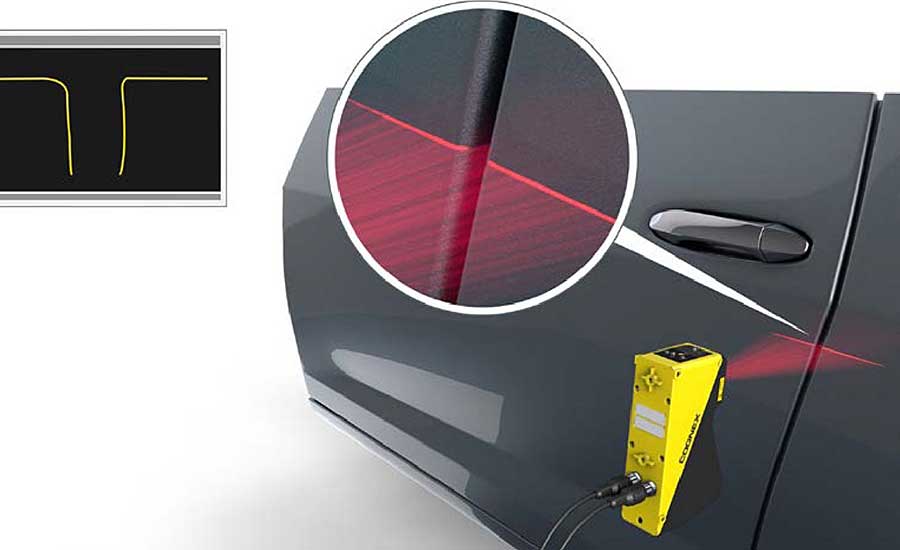

The automated gap-and-flush inspection system includes laser profilers (shown), machine vision controllers and an encoder connected to a PLC. Photo courtesy Cognex Corp.

A slightly crooked painting gets most people’s attention, whereas very few people will notice a car door that is askew by less than a millimeter. Catching that imperfection is often reserved for trained personnel on an automobile assembly line.

Such was the situation for Stellantis N.V. at its Brampton Assembly Plant in Ontario, Canada, until 2018. That year, the company (formerly known as Fiat Chrysler Automobiles N.V.) implemented an automated gap-and-flush inspection system by Cognex Corp.

The change was made for several reasons. For one, manual inspection requires the use of contact gauge tools that often scratch vehicles. Manual inspection is also more time consuming and offers no assurance that measurements are taken at the exact same point from one vehicle to the next.

In addition, manual gap-and-flush checks are done by batch instead of by individual vehicle. As a result, the potential existed for vehicles to pass through the line with unacceptable door geometries. This, ultimately, required more resources to identify and correct errors.

The Cognex system, in contrast, offers simple, accurate and noncontact inspection. It consists of four DS1300 laser profilers, two In-Sight VC200 machine vision controllers and an encoder connected to a Rockwell Automation PLC.

Stellantis engineers have two specific goals for the system, which is positioned directly after the door assembly station on the production line and before painting. One is to ensure that the gap between doors and panels on each Chrysler 300, Dodge Challenger and Dodge Charger is consistently within 0.2 millimeter of their design specification. The other is that their doors are flush or planar to neighboring panels within 0.3 millimeter.

For added flexibility, the Cognex system automatically adjusts its operation based on vehicle body style and whether it features two or four doors. System operation begins with the encoder tracking each vehicle frame as it moves down the production line.

When the PLC determines that a particular model is within 1 inch of the target area, it triggers the laser profilers—two on either side of the vehicle—via the controllers. Each profiler, in turn, makes a 2D profile of the door (at the top and near the bottom), after collecting data on its leading and trailing edges.

Because the profiler has a long measurement range, there is no risk of any vehicle scratching or a pinch point safety hazard to workers. In addition, system design discourages them from trying to pass between the profiler measurement system and automobile body during operation.

Stellantis especially likes that each profiler provides a highly accurate measurement on the Z axis. This capability verifies when both body panels are on the same plane, or if there are subtle differences that indicate they are out of tolerance.

The VC200 controller stores the most recent 5,000 gap-and-flush measurements, enabling engineers to download data as needed for reports and later analysis. These measurements are also recorded against vehicle history in the manufacturer’s Performance Feedback System, which allows for easy reference and correlation.

Best of all, the Cognex system provides 100 percent door and fender panel position compliance. For more information on inspection systems, call 855-426-4639 or visit www.cognex.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!