Better Bikes With 3D Printing

Simulation and analysis software improves 3D-printed structures for Urwahn Bikes.

The primary goal was to reduce the frame weight by pushing components like 3D-printed tubular and connecting elements to the limits while still guaranteeing product safety. Photo courtesy Urwahn Engineering GmbH

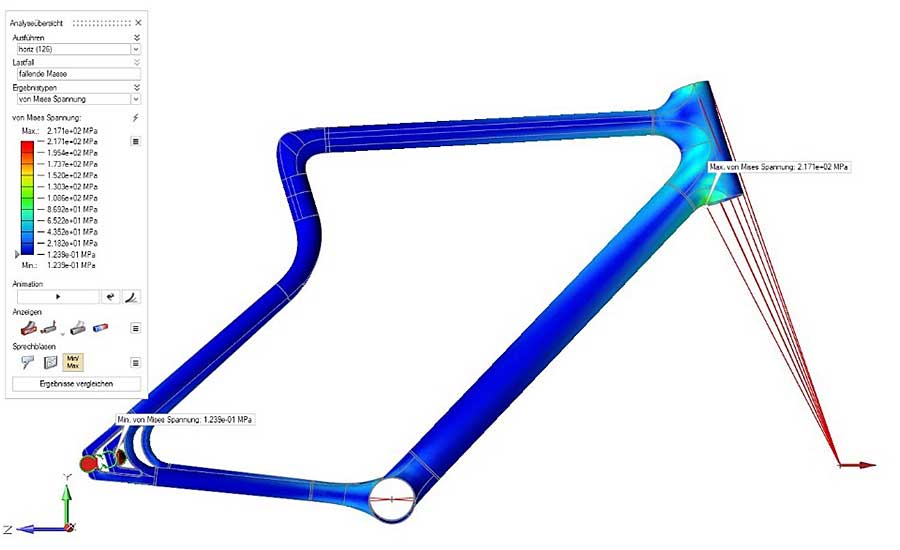

Simulating load cases on the steel frame structure in Altair Inspire enabled Urwahn to meet the DIN ISO 4210 safety standards. Photo courtesy Urwahn Engineering GmbH

This image shows how forces created by pedaling the bicycle might affect the frame. This helped engineers create improvements to meet safety regulation parameters. Photo courtesy Urwahn Engineering GmbH

Urwahn’s unique Softride frame geometry lacks a seat tube, which is intended to insulate the rider from unevenness and terrain. Photo courtesy Urwahn Engineering GmbH

Urwahn uses additive manufacturing to create its steel frames, which combine organic design with high brand recognition and high functionality. Photo courtesy Urwahn Engineering GmbH

Additive manufacturing has become a well-established process in bicycle manufacturing. While the average road bike might not have any 3D-printed components, high-end bike makers are appealing to competitive cyclists with additive manufacturing, using it to create highly custom and lightweight components.

One of the leaders in applying that technology is start-up Urwahn Engineering GmbH in Magdeburg, Germany. Founded in 2013 by engineer Sebastian Meinecke, Urwahn and its 20-person workforce make eight models of bikes and e-bikes that inspire riders with their streamlined designs and technical precision.

The company’s philosophy is based on four pillars: design, functionality, processing and sustainability. Urwahn uses additive manufacturing to create its steel frames, which combine organic design with high brand recognition and high functionality. The company’s unique Softride frame geometry lacks a seat tube, which is intended to insulate the rider from unevenness and terrain.

While many bikes are made from aluminum or carbon fiber today, Urwahn prefers locally sourced steel. “Compared to carbon and aluminum, steel is much easier to process, repair and recycle,” says Meinecke. “And, sourcing locally means short production and logistics routes, so we can also drastically reduce CO2 emissions for the benefit of our environment.”

The company uses additive manufacturing to make a variety of parts, including frame components. The company does not printing the entire frame, but rather those parts that matter from an engineering and design standpoint. The goal is to enable engineers to maximize performance, cost and aesthetic goals.

In addition to additive manufacturing, the process of making Urwahn bikes involves welding, grinding, painting and final assembly.

Simulation Software Plays Key Role

While bikes must meet many requirements to comply with DIN ISO 4210 safety standards, they must also be as light as possible to reduce raw material usage and create the best possible user experience. To meet these seemingly opposing requirements, Urwahn has always relied on simulation software. In 2020, when supervising a bachelor thesis on topology optimization and the redesign of an urban bike frame to reduce the wall thickness, Urwahn engineers needed simulation and analysis software that could optimize the steel frame’s build structure. The primary goal was to reduce the frame weight by pushing areas like 3D-printed tubular and connecting elements to the limits while still guaranteeing product safety.

However, engineers team could not rely on their existing simulation software, since the process they needed to map was too complex and time-intensive. Urwahn needed a platform that could help the team identify structures they could improve, study various components in terms of the existing load cases prescribed by DIN ISO, and recommend an optimized lightweight design in a timely manner.

Simulation and analysis software from Altair Engineering Inc. did the trick. Altair is a multinational information technology company headquartered in Troy, MI. Best known as the creator of HyperWorks CAE software, Altair provides software and cloud software for simulation, internet of things, high performance computing, data analytics and artificial intelligence.

Under a special program for start-ups, Urwahn received access to Altair Inspire, a powerful, easy-to-use topology optimization platform for design and engineering throughout the product development process. Thanks to Inspire’s intuitive user experience, the Urwahn team got started right away, without needing specialized training.

To meet DIN ISO 4210’s safety requirements, they simulated five load cases on the steel frame structure (three dynamic tests with vertical, horizontal and alternating forces, and two static tests of the frame and fork). In each scenario, Urwahn engineers studied the behavior of the 3D-printed parts and explored the impact of the material distribution on overall system behavior, aiming to minimize weight. Using the integrated topology optimization solver within Inspire enabled Urwahn to push the material usage limit, thereby reducing weight and costs, while keeping stiffness and other boundary conditions on target.

Thanks to Inspire, Urwahn studied the existing framework concept, detected limit values, and reduced wall thicknesses significantly by testing different load case scenarios on the structure. As a result, the team lowered the steel frame’s weight while maintaining its stiffness. In addition to reducing wall thickness by up to 15 percent, the Inspire results also implied that there is still room for improvement within safety regulation parameters.

“Altair Inspire simplifies simulation and provides fast and accurate results,” says Meinecke. “We quickly received the results we had hoped for to reduce the wall thickness, while maintaining the stiffness of our steel frame. Without Inspire, we would not have been able to achieve these results in such a short time frame. The knowledge we gained with Inspire helped us to take a different approach and will definitely help us to push the design of the components closer to their limits.”Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!