Oak Ridge National Laboratory Installs Xerox 3D Printer

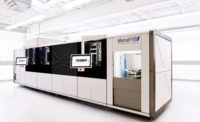

CARY, NC—Xerox Elem Additive Solutions has installed an ElemX 3D metal printer at the Manufacturing Demonstration Facility at Oak Ridge National Laboratory (ORNL).

ElemX is a liquid-metal additive manufacturing (AM) technology that uses aluminum wire as the feed stock. It is easily deployed and requires no special facility modifications for operation. Unlike many metal 3D printing technologies, parts made with ElemX require minimal post-processing.

“Developing metal AM technologies that are simpler to install and integrate into existing manufacturing operations will be key to increasing adoption throughout the industry,” says Tali Rosman, general manager and vice president of Xerox Elem Additive. “This installation will enable us to further refine our liquid metal AM technology and achieve our goal of creating more resilient supply chains for our customers.”

“ORNL has a long history of working with industry on alloy deployment and the improvement of material performance in AM,” adds Ryan Dehoff, section head for secure and digital manufacturing at ORNL. “This process is promising for high-volume applications, such as automotive [manufacturing]. Leveraging our experience with alloy development will help [Xerox] expand the available number of alloys and applications.”

ElemX is a safer and simpler metal 3D printing technology that can be used by manufacturers in the transportation, aerospace, defense and other industries. Until now, the ability to 3D print aluminum consistently and reliably has challenged the market. ElemX solves that problem. Unlike other metal 3D printing technologies, there are no hazardous metal powders with ElemX and no need for personal protective equipment or other considerable safety measures. The technology can be used to make spare parts, repairs and low-volume production parts.

For more information, click here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!