Researchers Advance 3D Printing to Aid Tissue Replacement

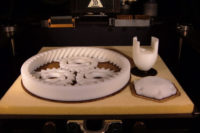

PULLMAN, WA—Researchers and professors in the Washington State University School of Mechanical and Materials Engineering have developed a unique scaffold on their 3D printers that can be fine-tuned to grow natural replacement skin, cartilage or other tissue. This scaffold is material that has been engineered to cause desirable cellular interactions and help form new functional tissues for medical purposes. Cells are often 'seeded' into these structures capable of supporting three-dimensional tissue formation.

"The success of this method in manufacturing functional tissues relies heavily on how well the fabricated structures mimic the native tissues," Professor Arda Gozen says. "If you want to grow cells and turn them into functional tissue, you need to match the mechanical environment of the native tissue."

The way that researchers have traditionally varied their scaffolds was to simply remove trusses to make them softer or stiffer–a method that is too simple to address all the needed complexity in tissue engineering.

"We don't have a lot of knobs to turn," Gozen says. "You need more degrees of freedom to create something softer or harder without changing the structure."

The team of researchers developed a new bioink material that allows for customizing properties to closer approach what cells might need. The ingredients for their scaffold include gelatin, gum Arabic, and sodium alginate, which are all common thickening agents used in many processed foods.

The work is still in its early stages, and the researchers would like to figure out how to more precisely tune the process and final material. They might look at varying the composition of their three materials or printing at different temperatures, for instance.

Trying to imitate the vast complexity of natural tissue remains a challenge. Even a simple millimeter-sized piece of cartilage on the knee, for instance, has three separate and distinct layers, each with different mechanical properties and functions.

"You're not assembling Legos here. It's always about replicating nature that works with the body," says Gozen. "You can make living structures, but they look nothing like the native tissue. Precision is key because there is no single mechanical property target for a single piece of tissue."

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!