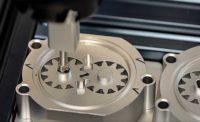

Robots have always struggled to match human touch. But, recent advances in sensor technology now enable the machines to process the sensitive forces needed for delicate assembly tasks, such as placing, inserting and tightening parts.

Force-control technology provides fast, tactile feedback to guide robots with unprecedented precision. Machines equipped with force control can assemble parts with tight tolerances.

Normally, robots are position controlled with a predefined path and speed. With force control, a robot reacts to its surroundings and deviates from the programmed path or speed based on feedback from a force sensor.

Most force-control sensors are six-axis, offering three linear and three rotational movements. However, there are also two-axis force sensors available with more limited movement.

Robotiq Inc. recently launched Force Copilot, an intuitive software program that operates Universal Robots’ e-Series embedded force-torque sensor. It accelerates the programming of a variety of applications, including part insertion and surface finding.

“Force Copilot’s sensing functions increase flexibility and reliability in assembly, finishing, machine-tending and pick-and-place applications,” explains Annick Mottard, product manager at Robotiq. “A suite of setup tools allows the user to hand guide the robot on complex trajectories.

“The software makes it easy to place objects precisely in jigs, trays and chucks, and it facilitates assembly applications through its alignment, indexing and insertion functions,” claims Mottard. “The intuitive interface unlocks finishing applications, with adjustable adaptive compliance and constant force for all robot axes.

“We want to free every production line operator in the world from repetitive manual tasks,” says Mottard. “With Force Copilot, we are making complex robot-movement programming accessible to anyone. Force Copilot works as the human operator’s guide, helping program the robot quickly and easily.”