Do You Really Need a Vision System?

Every manufacturer has one want and many needs. The want is universal—to be the leader in its industry or area of specialty. The needs are individual, and may concern issues as diverse as increasing capital, upgrading technology, expanding plant size or hiring more assemblers.

On the technology side, manufacturers of all sizes in various industries are increasingly deciding that they should have a vision system on their assembly line or lines. The question is, do they really need one? As always, the answer is, it depends.

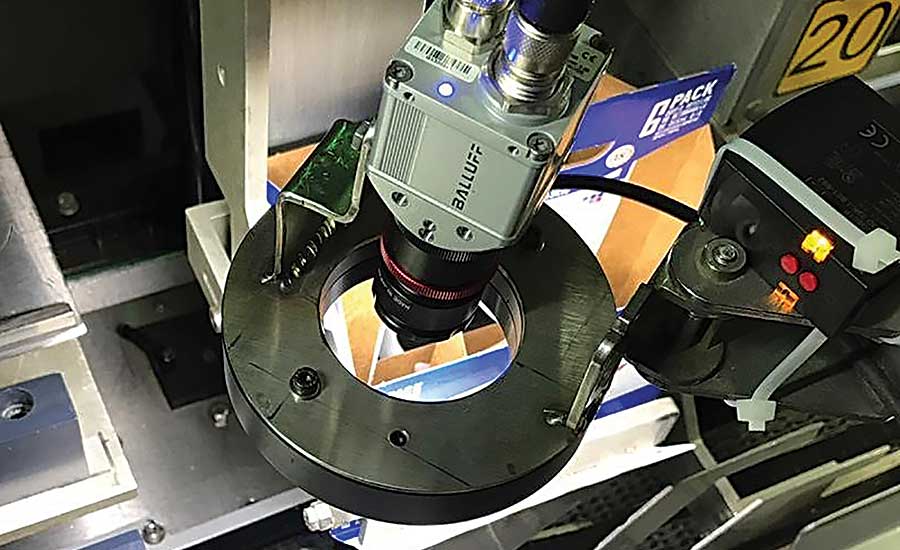

“The more things you need to inspect on a part, the more sense it makes to install a smart-camera- or camera-with-controller-based vision system,” says Chris Heberlein, sales director for machine and plant engineering at Balluff Inc. “If the application is a process control one that only involves determining the presence or absence, or correct position or orientation of a part in an assembly, then you can probably get away with a simple vision sensor. But, if there is one or more additional process control steps, then you need to seriously consider installing a vision system. After all, how much will a product recall cost you, financially and otherwise?”

Heberlein admits that, sometimes, it’s hard for a manufacturer to commit to a vision system, even when an application clearly needs one. Last fall, for example, he met with a Tier 1 automotive supplier that needed to have a robot accurately position different sizes of metal blanks into a press. Heberlein and the supplier’s representative discussed camera mounting options at length.

“I explained that the vision system could be equipped with multiple cameras, and that they can be mounted above where the robot grabs the blank,” explains Heberlein. “The vision system would then be taught to recognize each size of blank by using its correct coordinates so it gets properly positioned.”

The supplier didn’t commit to installing a vision system with Balluff components after meeting with Heberlein. And he still doesn’t know if the company ever did, or ever will, install a vision system.

When a company does install a vision system, it gains many benefits: consistent error proofing; improved product quality; increased productivity, production flexibility and floor space; tighter process control; reduced operating costs, downtime and scrap rates; more accurate inventory control; and improved worker safety.

Despite these benefits, however, engineers must still consider factors such as cost and simplicity when deciding whether a vision system is really necessary for the application at hand.

Key Questions

There are four types of assembly applications where machine vision is used. Some equipment suppliers refer to them as guide, identify, gauge and inspect, or GIGI. Heberlein prefers the categories of guidance, traceability, measurement and process control.

Guidance is concerned with using vision to guide a robot to a specific location to pick up a part. The camera can be mounted in a fixed location or it can be mounted directly on the robot. This application may also require a 3D vision system.

Traceability involves reading characters or machine-readable codes on a product. Measurement refers to the system determining the linear or angular measurement of a specific area on a part and ensuring that it’s correct. This is done quickly (within milliseconds), precisely and without contact.

“Process control relies heavily on the pattern matching capability of the image-processing software,” notes Heberlein. “The goal is to make sure the camera sees the exact part shape it’s supposed to see, instead of one with cracks, defects and other imperfections. Also process control can simply be to recognize the presence or absence of a shape and/or color.”

Once the application type is established, Heberlein discusses several questions with the manufacturer about the work environment, production volume, system setup and available budget.

“A vision system needs the right environment to be effective,” says Heberlein. “I need to know if the system will be subjected to wash-down, oils and air particulates. If so, we’ll need enough space to place the camera further away from such areas, and we’ll need a larger lens to still clearly see the part.”

High-volume applications tend to be more cost-effective for machine vision than low-volume ones—unless the latter involve very expensive parts or those with tight tolerances. Machine vision may also be a wise investment for manufacturers that frequently change parts.

Heberlein says it’s crucial to know who will setup the vision system. He says the in-house team or integrator should have some prior experience in all aspects of system setup.

As for budget, the end-user needs to know upfront that a full vision system costs many times more than a simple vision sensor. From a few thousand dollars to tens of thousands of dollars is realistic for a standard system, vs. $1,000 or $1,500 for a vision sensor, according to Heberlein.

“Budgetary restrictions are always important, although sometimes a vision system can prove to be more cost-effective than using several sensors in the long run,” says Keith Bowling, machine vision specialist at Edgewater Automation’s facility in Spartanburg, SC. “Consider the situation where a company has used several sensors to monitor a specific assembly process. The company can probably be just as successful with one camera that may cost less to buy and operate.”

Balluff’s BVS SC SmartCamera makes it possible to detect production defects in the manufacturing process early on and assures quality control of objects. It detects machine codes, text or serial numbers and assists robots in position finding. Easily set up with common Web browsers, the camera generates inspection programs and passes inspection results to the controller or file servers.

Manufacturers can incorporate the camera in a vision system using digital I/O, standard LAN, Profinet or Ethernet/IP. The quantity and format of acquired data can be adapted, and mass data kept out of the process network. Additional sensors can be integrated into the system via an IO-Link master interface.

Real-World Expectations

“The real question isn’t, ‘Does a manufacturer really need a vision system?’ but, ‘Does a manufacturer need to be convinced that it needs a vision system?’” opines Bowling. “Most of the time the answer is no. Then you occasionally come across a company that years ago used cameras for anything and everything because it was the thing to do. Things didn’t work out well for the company and now it wants to stay completely away from anything even related to vision.”

Bowling had such an experience a couple years ago at a Tier 1 automotive supplier that stamped various parts. He spent a half-day there and talked at length with the technical representative, who freely shared his bad experiences with vision.

Bowling says he explained the ways that vision could help the stamping process, and where and how cameras could be used at certain distances throughout the process. He also acknowledged that installing the vision system would be quite expensive, but very beneficial. The rep was unmoved.

“I tell each customer and prospective customer the science behind the vision system, what it can and cannot do,” says Bowling. “However, machine vision is a tricky thing, in that its installation and capability aren’t always a clear line in the sand, or a hardcore binary yes or no. Companies need to be more flexible regarding vision systems and stop having unrealistic expectations.”

Inspection and robot-guidance applications are the most common for Bowling, regardless of industry. The former typically involves using a vision system in place of a quality control inspector who did many inspection tasks. Robot guidance often requires the use of 2D vision, and on occasion, 3D vision is needed to better help the robot lift different types of parts off of a conveyor belt.

According to Bowling, mechanical constraints can often make a vision system more feasible than using sensors alone. For example, the need to inspect tiny parts may make it impractical to use large sensors or sensors too far away. A camera, however, can be positioned a few feet above the work area and equipped with a zoom lens that focuses right in to the affected area. This camera setup also eliminates the need for brackets at the spot of inspection.

Heberlein says that the main challenge he sees regarding machine vision is when an end-user has little or no experience with operating a vision system. This can lead to unrealistic expectations, with the company figuring that the system will solve its main problem—but not understanding that the system may not be able to solve other problems that arise.

“Application parameters may change over time,” notes Heberlein. “This can lead to the supplier and end-user not being on the same page from the beginning about which components to use in the vision system.”

“End-users need to focus on the ROI of the vision system from the start,” says Bowling. “If it’s not there, forget about using a vision system.”

Increasingly Connected

The use of machine vision for assembly and inspection applications is on the rise, and has been, for a long time. Heberlein points out that vision began to become popular in the 1980s and 1990s due to federal guidelines (Title 21 CFR Part 11) requiring track-and-trace systems in the food, beverage, pharmaceutical and cosmetics industries.

The auto industry remains one of the largest users of vision systems, as a result of steady growth for many years. A similar situation can also be found among semiconductor and electronics manufacturers, and steel producers.

“The increase in cobots and end-of-line robots is spurring growth in the use of vision as well,” explains Heberlein. “With cobots, the vision guidance ensures that parts are accurately retrieved without any chance of hitting other equipment, or worse, a nearby worker. Vision used with end-of-line robots helps manufacturers pick the correct parts, as well as increase throughput.”

“As automation increases, so does the need for vision, and automation is increasing across the board in every industry we serve,” notes Bowling. “Industry research indicates that the sales value of vision systems and components is still increasing by about 15 to 20 percent annually.”

Edgewater outsourced almost all of its vision system integration work until hiring Bowling in 2014. Before that, he had worked full-time in manufacturing for 25 years, and then simultaneously ran his own photo business while doing some vision-system installation work for a company that made inflator valves for safety air vests.

Today, Edgewater performs vision-system design and installation for companies in many industries—primarily automotive, but also white goods, medical devices and electronics. Bowling is involved in every application, no matter how simple or complex.

This heavy work load helps Bowling stay abreast of trends in machine vision. He cites two of note. One is an increasing resolution of the sensors within cameras for higher quality images.

The other trend is an increase in camera-to-PC-based vision systems, rather than smart camera-based ones. Companies are doing this to save money. Like smart cameras, those used in a PC-based system produce very large images—5 to 20 megabytes in size—but are much less expensive: $2,000 vs. $15,000 or $20,000. These cameras are also compatible with all of the latest interfaces, such as Camera Link, Camera Link HS, USB3.2 Vision and GigE Vision.

The Industrial Internet of Things is another reason for increased vision system usage. The high volume of data that vision equipment makes accessible helps manufacturers identify and flag defective products, understand their deficiencies, and enable fast and effective intervention in the connected factory.

“Industry 4.0 requires intelligent production systems, and that includes vision,” says Heberlein. “The best vision system for today is one that includes industrial Ethernet and other ways to quickly obtain and transport all images and related processing data.”

A controller can help achieve these goals, especially for any vision system that features non-smart cameras. The Linux-based BAE0103 SmartVision controller from Balluff controls all accessories used with GigE and USB3 industrial cameras. It features an integrated BVS Cockpit user interface that directly controls several industrial cameras. The interface also makes all camera data available to the central controller over various network interfaces.

If necessary, the interface can be installed and used on Windows-based terminal devices. This lets an end-user configure and control the connected industrial cameras with its own PC.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!