X-Rays Help Researchers Identify Cause of Metal 3D Printing Defects

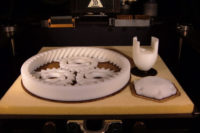

PITTSBURGH—Researchers from Carnegie Mellon University and Argonne National Laboratory have identified how and when gas pockets form during 3D printing with the help of x-rays—a discovery that could dramatically improve the 3D printing process. The scientists used the extremely bright high-energy x-rays at Argonne’s Advanced Photon Source to take super-fast video and images of a process called Laser Power Bed Fusion, in which lasers melt and fuse material powder together.

The lasers scan over each layer of powder to fuse metal where it is needed and literally create the finished product from the ground up. Defects can form when pockets of gas become trapped into these layers, causing imperfections that could lead to cracks or other breakdowns in the final product.

Until now, manufacturers and researchers did not know much about how the laser drills into the metal, producing cavities called “vapor depressions,” but they assumed that the type of metal powder or strength of laser were to blame. As a result, manufacturers have been using a trial-and error approach with different types of metals and lasers to seek to reduce the defects.

This latest research shows that these vapor depressions exist under nearly all conditions in the process, no matter the laser or metal. Even more important, the research shows how to predict when a small depression will grow into a big and unstable one that can potentially create a defect.

Under perfect conditions, the melt pool shape is shallow and semicircular, called the “conduction mode.” But during the actual printing process, the high-power laser, often moving at a low speed, can change the melt pool shape to something like a keyhole in a warded lock: round and large on top, with a narrow spike at bottom. Such “keyhole mode” melting can potentially lead to defects in the final product.

The research shows that keyholes form when a certain laser power density is reached that is sufficient to boil the metal. This, in turn, reveals the critical importance of the laser focus in the additive manufacturing process, an element that has received scant attention so far, according to the research team.

“The keyhole phenomenon was able to be viewed for the first time with such details because of the scale and specialized capability developed at Argonne,” says Tao Sun, an Argonne physicist and an author on the paper. “The intense high-energy X-ray beam is key to discoveries like this.”

The experiment platform that supports study of additive manufacturing includes a laser apparatus, specialized detectors, and dedicated beamline instruments. In 2016, the Argonne team, together with their research partners, captured the first-ever X-ray video of laser additive manufacturing at micrometer and microsecond scales. That study increased interest in the impact Argonne’s APS could have on manufacturing techniques and challenges.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!