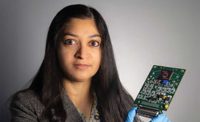

GREENBELT, MD—Technologist Mahmooda Sultana and her team at the NASA Goddard Space Flight Center here have received a $2 million development award to spend the next two years advancing a nanomaterial-based detector platform. This platform measures only 2 by 3 inches, yet is capable of sensing minute concentrations of gases,vapor, atmospheric pressure and temperature, and then transmitting the data via a wireless antenna.

If successful, the platform could benefit all of NASA's major scientific disciplines and efforts to send humans to the Moon and Mars. These tiny platforms could be deployed on planetary rovers to detect small quantities of water and methane, for example, or be used as monitoring or biological sensors to maintain astronaut health and safety.

Central to the effort, funded by NASA’s Space Technology Mission Directorate’s Early Career Initiative is a 3D printing system developed by Ahmed Busnina and his group at Northeastern University in Boston. Each 3D-printed sensor is capable of detecting a different gas, pressure level or temperature.

Under her partnership with Northeastern University, Sultana and her group will design the sensor platform, determining which combination of materials are best for measuring minute, parts-per-billion concentrations of water, ammonia, methane and hydrogen. The team will then use its Nanoscale Offset Printing System to apply the nanomaterials. Once printed, Sultana’s group will functionalize the individual sensors by depositing additional layers of nanoparticles to enhance their sensitivity, integrate the sensors with readout electronics, and package the entire platform.

The approach differs dramatically from how technologists currently fabricate multifunctional sensor platforms. Instead of building one sensor at a time and then integrating it to other components, 3D printing allows technicians to print a suite of sensors on one platform, dramatically simplifying the integration and packaging process.