Sensors Make Robots Smarter When Inserting Vehicle Windshields

Bluewrist Inc. has developed an advanced 3D machine vision system to improve robotic insertion of front and rear windshields. Photo courtesy Wuhan TopEagle

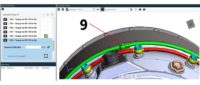

After a six-axis robot moves the windshield to a predetermined insertion point, sensors project red laser lines across the four edges of the windshield and autobody aperture. Photo courtesy Wuhan TopEagle

Inserting glass windows into car bodies has been, and remains, a challenge for automotive OEMs. Manual insertion is labor intensive and imprecise, and carries with it the risk of bodily injury to assemblers due to broken glass.

Alternatively, robotic insertion methods are complicated because the car body location may vary slightly depending on vehicle size. Overcoming this problem requires the use of a vision guidance system to ensure that the end effector always properly positions the glass.

Systems integrator Bluewrist Inc. recently developed an advanced 3D machine vision system to improve robotic insertion of front and rear windshields. The system consists of Bluewrist’s proprietary EzRG robot guidance software and four Gocator 2300 series 3D smart sensors mounted on the robot’s end effector. Made by LMI Technologies Inc., the sensors are immune to robot movement and vibration.

On the assembly line, a large six-axis robot picks up the windshield from a fixed location using suction cups (that extend from the effector) and moves the glass to a predetermined insertion point. There, the sensors project red 635-nanometer laser lines across the four edges of the windshield and

auto-body aperture.

After reflected laser light is digitized by a camera embedded in each sensor, built-in measurement tools determine the X, Y and Z coordinates of the windshield and send this data to an external Advantech PC equipped with EzRG software. Within 0.5 second, the software calculates transformation data in six degrees of freedom and sends the results to the robot controller.

The robot uses the calculated transformations to guide the windshield into position on the aperture and insert the glass. Guidance accuracy is ±0.2 millimeter. The system’s high accuracy and speed also make it effective at installing vehicle hoods, trunk lids and doors.

Najah Ayadi, president of Bluewrist, says the software offers several robot guidance and user-frame calculation methods, including best-fit measurement, 3-2-1 fixturing and a user-frame formulas interpreter. A user-friendly graphical interface lets users quickly and easily modify offsets.

“Gocator sensors [are] much more robust [than conventional industrial cameras] when it comes to locating or taking measurements under all of these conditions,” explains Ayadi. “Its built-in smart measurement and exposure control delivers a 3D solution at incredible value.”

Gocator smart sensors perform 100 percent noncontact product inspection at scan rates up to 32 kilohertz. They accurately measure all colors (including painted surfaces) and produce high-resolution images at distances up to 2 meters.

Compact and rugged, the sensors easily mount on the end effector without interfering with other components. They fit in small spaces, and their light weight does not add significant mass to the effector. The sensors integrate seamlessly with robotic machinery, and can be set up and controlled from a Web browser.

Bluewrist develops industrial automation solutions related to robotics, machine vision and software. Its SPC Works software instantly collects dimensional data from measurement systems and generates various reports.

LMI specializes in developing sensors for 3D scanning and inspection applications in the automotive, electronics, medical and other industries. For more information on 3D smart sensors, call 604-636-1011 or visit https://lmi3d.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!