Best Practices for Press-Fit Assembly

Parts of various sizes, shapes and materials are often assembled with an interference fit.

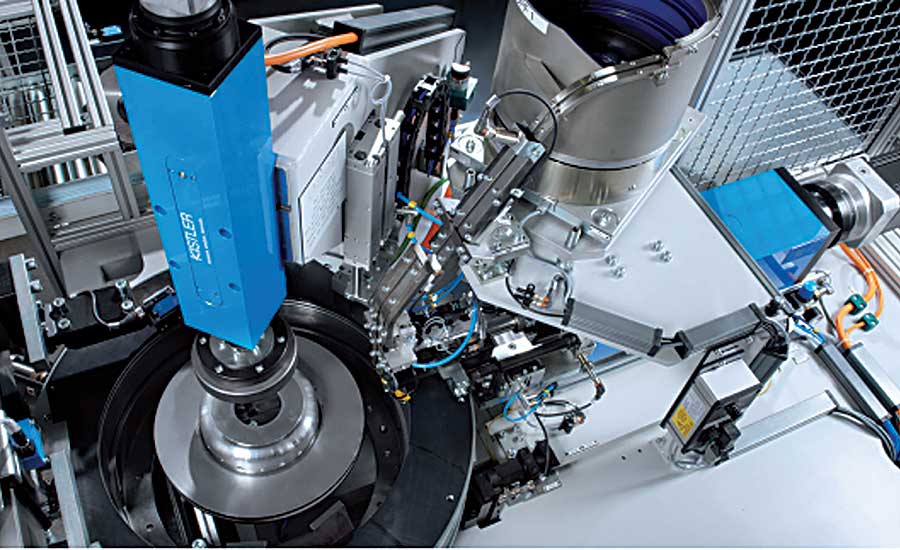

In this application, a piston assembly is loaded into the fixture prior to pin insertion. Spacer blocks on the right allow for various piston heights and sizes. Photo courtesy BalTec Corp.

Press-fitting is used for small and large parts. Here, studs are inserted into a forklift wheel hub. Photo courtesy FEC Automation Systems

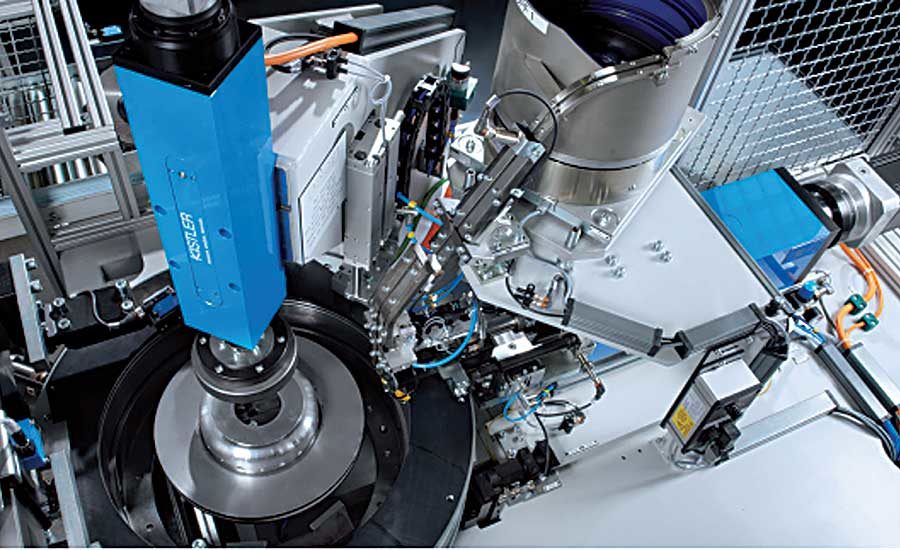

Automotive manufacturers frequently use press-fit assembly. This unit press-fits a component into a brake disk. Photo courtesy Kistler Instrument Corp.

In manufacturing, ironclad formulas for success are hard to come by. This is especially relevant for press-fit assembly, a process whereby one part is inserted tightly into a hole in another part with a single quick stroke (1 to 2 seconds). Design engineers use many formulas to estimate the required force and related pressures and stresses for each press-fit application. However, those calculations can never replace real-world lab testing, or trial and error on the production line.

“Formulas can provide a starting point in the process of designing parts for press-fit, but they don’t take into account the many variables that come into play during assembly,” says Chuck Rupprecht, general manager at BalTec Corp. “Factors like inconsistent material quality, different surface finishes and ambient humidity can result in calculations that are way off. The truth is, you must install actual parts to determine the proper material and force requirements for an application.”

BalTec offers several manual, pneumatic and hydropneumatic presses for press fitting. Customers include automotive, medical and other industrial manufacturers such as HVAC-component makers. One latter company recently asked BalTec to customize two DA-850 pneumatic presses so they can press-fit pins into 40 different-height pistons for refurbishing HVAC compressors.

Each direct-acting press features a ram that produces up to 8.5 kilonewtons of force and a stroke up to 80 millimeters. The press’s upper tooling is able to insert pins in pistons of all heights, whereas its fixture has quick-change spacer blocks that accommodate height variations. A pneumatic clamp device secures the piston in place during pin insertion. Force and distance monitoring triggers an audio sound and visual message to indicate whether the specific process is OK or not OK.

Pistons are a good candidate for press-fit assembly, along with many other types of parts: bearings, rotors, gears, shaft collars and bushings. The main reasons manufacturers prefer this process are that it’s simple and relatively inexpensive. Further enhancing press-fit’s appeal is it can be performed with several types of presses, on parts of different shapes, sizes and materials.

Part Design Priorities

“When designing a part for press-fit, engineers need to focus on one question: What is the part’s function in the assembly?” says Hiroyuki Natsume, joining systems team leader of the IPC division at Kistler Instrument Corp. “This question must be emphasized in every aspect of part design, regardless of whether the assembly is simple or complex.”

“When designing a part for press-fit, engineers need to focus on one question: What is the part’s function in the assembly?”

The first design factor is size. Press-fit assembly involves the insertion of one part that is slightly larger than the mating hole. The assembly stays in place through friction and the force of the two parts pushing against each other. How much larger the inserted part needs to be relative to the hole will vary, although typically it’s 0.0005 to 0.002 inch.

Mike Brieschke, vice president of sales at Aries Engineering, says a 0.25-inch-diameter metal dowel that is press-fit into a mild steel hole usually has an interference of ±0.0015 inch. Parts in noncritical assemblies tend to have looser tolerances.

“As a general rule of thumb, the larger the diameter of a bearing, bushing or pin, the larger the tolerance range,” Brieschke points out. “The inverse is true for smaller-diameter pieces.”

Brieschke says a 2-inch-diameter bearing that is pressed onto a metal shaft, for example, could have a tolerance range of 0.001 to 0.01 inch due to the larger relative diameter of the two pieces. In contrast, smaller bearings used for automotive parts, like transmission housings and engine components, often have a tolerance range of just a few microns.

Regarding shape, most press-fit parts are round, but they can also be oval, square, rectangular or triangular. Inserted parts may be solid or hollow. Keith Lowery, servo press product specialist at FEC Automation Systems, notes that nonround parts may require an extra step to ensure proper orientation, resulting in longer cycle times. Large parts require a press that provides higher and more consistent force and sufficient part access.

Part alignment is equally important for a good press-fit assembly, according to Natsume. He says the best way to prevent misalignment is to use the right tooling and fixturing.

To enhance joint strength, part edges may be designed with indentations or projections. Lowery says that knurls enable the inserted part to bite into the mating part and help prevent the joint from moving when exposed to high torque forces. In plastic and electronic assembly, grooves or barbs on the mating part help prevent the joint from being pulled apart.

Press-fit parts are made of metal, plastic or rubber, and similar- or dissimilar-material parts can be joined. When they are dissimilar, engineers should choose materials with similar coefficients of thermal expansion, but different hardness ratings.

“The best scenario is when both parts are made of the same material and hardness,” says John Lytle, engineering manager at Promess Inc. “The worst is when one material is much harder than the other.”

As an example, Lytle cites the pressing of a steel-encased rubber bushing into aluminum control-arm steering components for vehicles. Much high press-fit forces are required when one part is made of steel and one of aluminum.

Lowery says that, when press-fits are subject to wide temperature changes, it’s important to choose materials with similar coefficients of thermal expansion. Failing to do so when press-fitting a steel bearing in an aluminum housing, for example, could result in the latter expanding more than the steel—and the bearing falling out.

According to Rupprecht, die-cast metals and glass-fiber-reinforced plastics are brittle materials and must be press-fit with the exact amount of force. Pressing a hard part into a thin-walled aluminum or plastic part with too much force can easily disfigure the mating part. Burrs or particulates on the inserted part can also cause damage.

Other types of plastics also have limitations. Somewhat-flexible polycarbonate isn’t recommended for shaft hubs because it doesn’t tolerate excessive circumferential stress. More flexible plastics, such as nylon, ABS and thermoplastic polyurethane, can better handle this stress, but may exhibit more stress relaxation over time.

“The automotive industry is increasingly using parts made of lighter materials to lessen vehicle weight, and this shift has led to an increase in press-fit applications to eliminate fasteners,” explains Natsume. “Sometimes this requires plastic or metal parts to be inserted into those made of carbon-fiber-reinforced plastic, such as rear spoiler wings, and other exterior and interior components.”

Smooth and Secure

Press-fit parts don’t always go together smoothly. When that happens, manufacturers have a couple options to overcome the problem. One is to place a taper on the inserted part and a chamfer on the mating part. Another is to apply lubrication, which prevents marring and galling (wear between sliding surfaces) on hard parts and the stick-slip (jerking) motion of either part. It also lessens the required insertion force to prevent part deflection. Lytle says rubber bushings that get pressed into metal are a good candidate for a small amount of lubrication, as are steel or titanium valve guides that get pressed into an aluminum cylinder head.

Lubrication is frequently used in the press-fitting of compliance pins in PCBs to reduce board stress due to undue press force, according to Lowery. He says a light spray of lubrication is used in these applications.

While pins may or may not require a tiny amount of lubrication, other parts need a more significant amount to enable a good press-fit, claims Brieschke. Wide and long bushings, for example, need to be lubricated all around to help them insert smoothly into respective sleeves. Aries offers an optional lube tray with its servo actuators that automatically applies the lubricant to bushings and bearings before pressing.

Although the vast majority of press-fits are strong enough to stand on their own, some joints require adhesive bonding. The adhesive completely seals the joint, prevents corrosion and distributes stress more evenly. It also allows engineers to loosen the tolerance requirements for the parts and reduce their bulkiness, which is needed to generate the pressure that holds the parts together.

There is a downside, though, to using an adhesive: It significantly increases the amount of force needed to assemble the parts. As a result, assemblers may need to increase press force or ram speed.

“I don’t see adhesives used often in press-fit assembly,” says Dave Zabrosky, sales manager of Schmidt Technology. “But when I have, it’s to better hold together two dissimilar materials that have different coefficients of thermal expansion.”

Equipment Essentials

Manual, pneumatic, hydropneumatic and electric servo presses can be used to assemble press-fits. Zabrosky says that manual presses are relatively low-cost, allow for simple part fixturing and can be equipped with force-distance monitoring. Their negatives are low production and poor ergonomics for the assembler.

Pneumatic presses provide more consistency in applied force and ram speed than a manual model, but lack the control and programmability of a servo. In addition, Zabrosky notes, air is costly to generate. A hydropneumatic press generates its maximum force over a small distance, making it a good choice for high-force applications requiring short power strokes.

“Without a doubt, servos offer the most precise control of ram position and speed for accuracy and repeatability,” says Zabrosky. “However, if a high level of precision isn’t needed, I’d recommend the company use a manual or pneumatic press instead, because they are cheaper and require less maintenance.”

High-volume assembly is needed to justify the servo’s higher upfront cost, confirms Lowery. Other benefits of the servo press include flexibility for high-mix operations, energy efficiency, quiet operation and a relatively small footprint.

Several factors determine how much force is needed to press parts together. Part size, thickness and geometry are important, along with the hardness, slipperiness and surface finish of the component material. In addition, designers need to need to know the exact amount of interference between the parts (i.e., the difference in size between the inserted part and the hole) and the length of the press-fit.

Among the biggest users of press fits are manufacturers that assemble automotive, medical, white goods, solar energy and consumer products. Examples of automotive products that require a high, medium and low press force, according to Lytle, are an axle tube insertion (250 kilonewtons), a valve guide into a cylinder head (20 kilonewtons) and a motor stator onto a shaft (300 newtons).

“Manufacturers often say they need a safety factor of 20 percent for presses used in press-fit assembly,” says Zabrosky. “But, our part testing indicates that 50 percent is more appropriate.”

Another tool that significantly enhances press-fit assembly is force and distance (displacement) monitoring, says Zabrosky. The force sensor is installed between the cylinder and the ram, and measures the force produced during the entire assembly cycle.

The distance sensor (or transducer) is positioned near the force sensor so that the press controller can display curves of force over distance or force over time. Through the controller, engineers can also set upper and lower limits for the pressing force. Should it fall above or below the set figure, an alarm is signaled.

“Force and distance monitoring is a great way to gain valuable information about the quality of the parts and the assembly—so long as the press frame is properly designed,” concludes Brieschke. “If the frame deflects too much, the resulting force-distance curve will be skewed from actual results. The best way to prevent deflection is to engineer enough strength within the frame design or use reinforcements.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!