GE ‘Predix’ the Future of Manufacturing

General Electric’s ‘Brilliant Factory’ initiative is driving a new era of production.

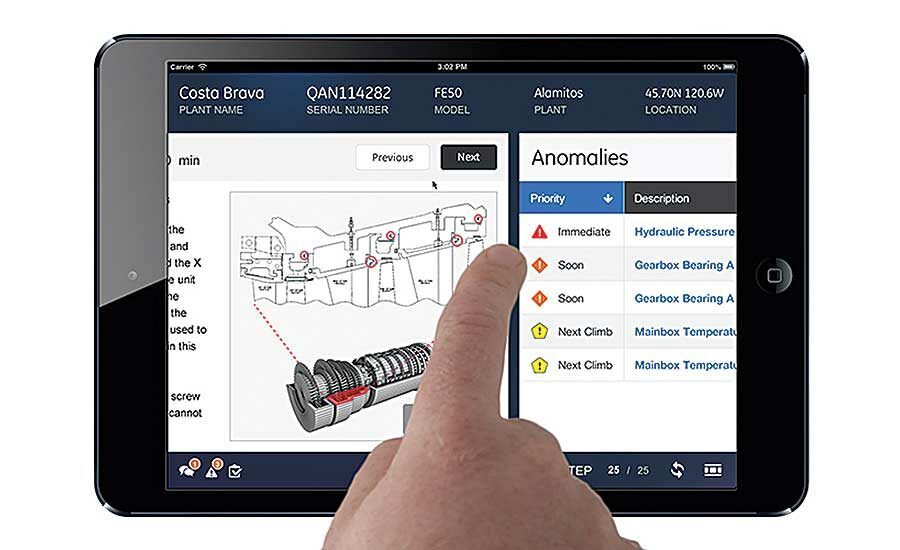

General Electric is in the midst of a major initiative to redefine manufacturing in the 21st century. Illustrations courtesy General Electric Co.

General Electric defines its Brilliant Factory concept as “boosting productivity by reimagining the way we design, manufacture and service products.”

General Electric has invested more than $1 billion to develop Predix, a cloud-based operating system for industrial operations.

General Electric is creating “digital twins” for all of its products, such as jet aircraft engines.

General Electric is developing a vast network of sensor technology and smart software to create a “brilliant factory.”

With Predix, GE can tell customers when wind turbine parts need to be serviced or replaced.

General Electric engineers are using augmented reality technology to examine parts and production processes using three-dimensional techniques.

One hundred years ago, a vertically integrated manufacturing complex in Schenectady, NY, defined the company behind the famous blue monogram. Today, the future of General Electric is in San Ramon, CA. That’s the home of GE Digital.

America’s largest industrial conglomerate is in the midst of a major initiative to redefine manufacturing in the 21st century. The 125-year-old organization is developing a vast network of sensor technology and smart software to transform itself into a “brilliant factory.” The goal is to create a companywide system of connected machines and digital production plants.

General Electric has been synonymous with Six Sigma for the past two decades. For the next 20 years, the company plans to be equally well-known for its role in driving the industrial Internet. Indeed, GE wants to make data just as important to its diverse manufacturing operations as robots, skilled labor, and nuts and bolts.

General Electric defines its Brilliant Factory concept as “boosting productivity by reimagining the way we design, manufacture and service products.” It consists of the following four components:

- Additive Manufacturing—“a method to build 3D objects by adding layer-upon-layer of material, also known as the industry version of 3D printing.”

- Advanced Manufacturing—“cutting-edge technology and new manufacturing processes to lower cost and accelerate the innovation, speed and performance of industrial products.”

- Digital Maturity—“digital analytics and insights that improve productivity and connectivity.”

- Lean Manufacturing—“a systematic method to maximize customer value through the elimination of waste within a manufacturing system.”

General Electric claims that it is “inventing the next industrial era to move, power, build and cure the world.” A typical GE jet engine or locomotive already contains hundreds of sensors. By 2020, 10,000 gas turbines, 68,000 jet engines and more than 100 million lightbulbs will be connected to the Internet.

“We are just beginning our transformation as the digital industrial company,” writes Jeffrey Immelt, CEO and chairman of the board, in GE’s 2015 annual report. “The Internet has had a massive impact on consumer productivity and commerce. Its impact on industrial markets is just now being realized.

“At GE, we have decided to generate and model this data ourselves—both inside the company and with our customers,” adds Immelt. “Our digital industrial capabilities will expand our growth rate, improve our margins and bring us closer to our customers.

“There was a time when every sale had a clear endpoint, followed only by routine service and maintenance,” adds Immelt. “Now, sensors on our products send constant streams of data, analyzed and translated into upgrades that drive productivity in industries where even the smallest incremental efficiency can mean very large gains.

“Capturing it will be a mission in every one of our businesses,” claims Immelt. “Our aspiration is to offer with every GE product a pathway to greater productivity through sensors, software and big-data analytics.”

A key element of that strategy is Predix, a cloud-based operating system for manufacturers. General Electric wants it to become for machines what Android is for smartphones.

Since 2011, GE has invested more than $1 billion to develop Predix. Along the way, it has hired hundreds of software engineers from Silicon Valley giants such as Apple, Facebook and Google.

Predix was initially developed internally to leverage data and drive productivity at GE’s various business units, which operate more than 400 manufacturing facilities around the world. According to Immelt, this includes making GE’s factories “brilliant” by taking analytics and combining them with lean manufacturing and optimal productivity to improve the speed and efficiency of operations.

Because it’s designed to be an “open” platform, GE began marketing the system to external customers last year. It hopes to grow Predix into a $4 billion business unit by 2020.

“Field-tested and optimized within GE’s own factories, Predix maximizes manufacturing production performance through advanced real-time analytics to enable all manufacturers to realize [our] Brilliant Factory vision,” says Jennifer Bennett, general manager of GE Digital’s manufacturing software initiatives. “Today’s demands on manufacturers are driving an unprecedented rate of change, innovation and agility.

“Manufacturers are challenged to decide what to build, how to build it, where and when to build it, and how to efficiently maintain it,” adds Bennett. “We believe that the key to optimizing the full product life cycle from design to service is through analytics of data that has been traditionally locked inside corporate silos.”

More than 19,000 developers around the world are currently building various apps on the Predix platform. This enables engineers to write apps, harvest data from machines and send that data to the cloud for analysis. For example, Schindler Group, a leading manufacturer of elevators and escalators, is using Predix to optimize the power consumption of its products.

To support Predix customers, GE organizes an annual Mind+Plus Machines conference in San Francisco. This year’s event is Oct. 25-26. It also hosts an event in Las Vegas called Predix Transform, which is scheduled this year for July 11-12.

Ambitious Analytics

ASSEMBLY recently asked John Magee, chief marketing officer for Predix, to explain how General Electric plans to transform the manufacturing world through its ambitious digital initiative.

ASSEMBLY: What is data analytics? How is it different than predictive analytics?

Magee: Data analytics is the process of collecting data so that it can be analyzed. It looks at past histories and patterns, then “marries up” that data with statistical approaches and physics-based models.

If you have a physics-based model of a machine, you can make accurate predictions about how it’s going to behave. What-if scenario modeling is another approach that falls under predictive analytics.

Making that process easier for customers is a big part of what Predix does. They don’t need to have a team of data scientists. We’re putting analytic algorithms that we’ve developed into Predix. They can now be deployed in different industries on different pieces of equipment.

ASSEMBLY: Why is data analytics important to the future of manufacturing?

Magee: The manufacturing industry has made great strides in efficiency through Six Sigma, lean, automation and robotics. In many ways, we’ve taken those areas as far as they can go in terms of squeezing out real significant productivity gains.

We see the next phase of efficiency and productivity coming from data analytics. That will give engineers better insight into how to operate manufacturing processes and machines.

The systems that many companies have already put in place are silos. However, a lot of manufacturers need an end-to-end picture of their operations from a data perspective.

With all the data that gets collected, we can start to be more predictive and do what-if analysis. For instance, based on patterns generated from historical data, we can assume there might be a problem with uptime of a critical piece of equipment. Or, if we take down a line for service or add more capacity, we can model the impact on the supply chain and the throughput of the overall operation.

We talk a lot about software, but data is really the key. Data is what drives the insights that drive the business outcomes that people are looking for today.

ASSEMBLY: What is Predix? What makes it unique?

Magee: Predix is a software platform. It consists of a cloud portion and an “edge” part. This system can sit out on the edge of a piece of machinery, such as a metal stamping machine. Predix is a single system that provides a complete, edge-to-cloud solution.

Rather than sending everything into the cloud, Predix can start running analysis directly on the machines at the edge of the system. It gives companies the ability to place machine apps anywhere they need to be, from the smallest medical device, to a controller, a network gateway or router, ultimately connecting to the cloud.

This means that programs can run faster and machines can quickly use the analyzed data to fix themselves. The edge is the place where the cloud meets the customer environment.

We were looking for a way to make all kinds of different machines intelligent by being able to aggregate sensor data. But, we also needed the scale and the computer power of the cloud. By combining those two components together, we can do analytics on a machine and look for an anomaly or detect a potential problem. With the cloud, we can collect data from machines all over the world and then run very sophisticated analytic algorithms on all of that data so we can be smarter.

Predix also enables “digital twin” applications, which was recently named by Gartner Inc. as one of the top strategic technologies for 2017. The idea of a digital twin is that for any physical device, you can have a software representation of that piece of equipment all the way through its life cycle. So, what you know about that asset gets richer and richer.

For instance, with a jet aircraft engine, GE engineers can look at it in new ways—not just in terms of its assembly history and part numbers. They can look at how the engine has performed in service. For instance, did it fly through certain air space in the Middle East where sand and grit become an issue? When was the engine last serviced? What parts were replaced on it and where did they come from?

By building this knowledge, we can start to treat each piece of equipment as the unique snow flake that it is, based on how it has been operated.

The other part of the digital twin concept that people are really excited about is that you’re not just getting information about one piece of equipment. Because of the cloud and the way that Predix can aggregrate all the data, engineers can pull information from all of the motors, pumps or valves of a specific type in use all around the world. You get smarter and smarter about things such as “what’s the best way to operate and service that equipment”?

When it’s time to redesign the next generation of that product, you’ve got a rich set of data and learnings that can be folded into the design process. That sort of loop is the beauty of the digital thread. It provides a life cycle that goes through design, manufacturing and service.

It’s analogous to the way that many companies integrated enterprise resource planning systems. The goal wasn’t just to automate financials or supply chains—it was to have the data flow through the organization and its processes. The digital thread is the equivalent of that for the physical manufacturing-based world.

General Electric has already created living, digital profiles of more than 550,000 industrial machines in the field. This software model of a physical asset or process will make it possible to manage more precisely than we ever thought possible and deliver better outcomes. It will also create new business models and services for GE’s customers and our businesses.

On the GE90 engine, we have used digital twins to increase fleet availability, while saving tens of millions of dollars in unnecessary service overhauls. In rail, we are using digital twin models of the Evolution Series locomotive to enable our customers to minimize fuel consumption and emissions.

ASSEMBLY: How does Predix address the complex, changing needs of manufacturers—both today and tomorrow?

Magee: To be able to aggregrate data, you need to leverage computing on the edge. Traditional control systems, such PLM and SCADA, tend to be siloed. Predix has edge computing technologies that make it easier to get at that data. Combining that with the analytic capabilities, we can start to do things like give people end-to-end visibility on their operations.

With the what-if scenario modeling, manufacturers can make better decisions at the level of an individual operator or at the level of an executive who’s looking at multiple plants and trying to optimize all aspects of their performance.

There’s a lot of opportunities for manufacturers to optimize their plant floor operations, and to improve the uptime and reliability of their products. Many companies are currently developing products that are connected.

Whether they make things as diverse as snow blowers or forklifts, engineers are asking themselves if they can put sensors on their products to learn more about how customers use them. That kind of information can affect the design of their next products. It can also transform the way that manufacturers interact with customers and service their products.

ASSEMBLY: What is GE’s vision for the future of manufacturing? What role does Predix play in GE’s Brilliant Factory initiative?

Magee: We are quite bullish on the industrial Internet and its potential to transform GE and the manufacturing world.

With our Predix platform and our Brilliant Manufacturing Suite, we are delivering solutions that enable manufacturers to use tools, such as connectivity and data analytics, to get a 360-degree view of all their upstream and downstream operations. They can improve yield, improve safety, and improve integration between their customers and their supply chain partners.

As a leading manufacturer ourselves, we’ve proven out these technologies and solutions in our very demanding production environments. Around the world, we’ve got facilities that have been designated as brilliant factories. They’re using Predix to optimize their operations. It’s been very successful for us internally.

ASSEMBLY: Can you provide a few examples of how Predix is being used by engineers within some of GE’s business units to transform the way that products are designed and manufactured?

Magee: GE Aviation maintains a digital twin for every jet aircraft engine that it produces. We’re able to improve the serviceability of those engines, which improves uptime for commercial airlines. We can tell them the optimal schedule for service and predict when something needs to be fixed before it turns into a problem.

Predix software is also operating on many of our wind turbines. We can tell customers when certain parts need to be serviced or replaced. But, we can also go to the next level and affect how an individual turbine is operating within a wind farm.

We’ve been able to adjust performance factors, such as the pitch of a blade, or angle a turbine so that it’s not in the exhaust track of another machine next to it. We’ve been able to optimize electricity yield improvement by as much a 5 percent, just through software.

With smart, connected locomotives, we can optimize the performance of an individual machine, in addition to the throughput of an entire rail network. Predix allows our customers to operate trains at the right speed to optimize fuel consumption and on-time delivery.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!