Driving Thread-Cutting and Thread-Forming Screws

With the proper torque, these fasteners create mating threads in the base material and generate adequate tightness in the joint.

The AST11 Controller relies on a “Friction Torque Value Procedure” to accurately calculate friction torque and apply consistent clamp load when driving thread-cutting or thread-forming fasteners. Photo courtesy DEPRAG Inc.

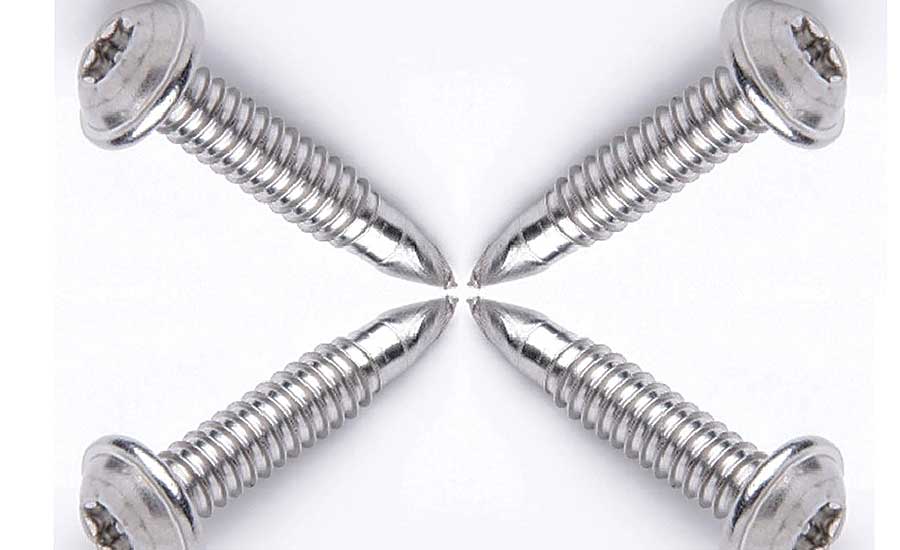

Rolok thread-rolling screws feature a thread with three asymmetrical lobes that form mating threads. Photo courtesy Semblex Corp.

HET handheld electric screwdrivers provide 0.1 to 30 newtonmeters of torque. Photo courtesy Weber Screwdriving Systems

Polyfast thread-forming screws have 45-degree asymmetrical threads, providing a narrow shank and a 26-degree point that eases installation. Photo courtesy Semblex Corp.

The FLOWpoint Delta PT thread-forming screw features a thread with 30-degree flanks that produce high tensile strength, torsional strength and clamp loads, but little radial force. Photo courtesy EJOT USA

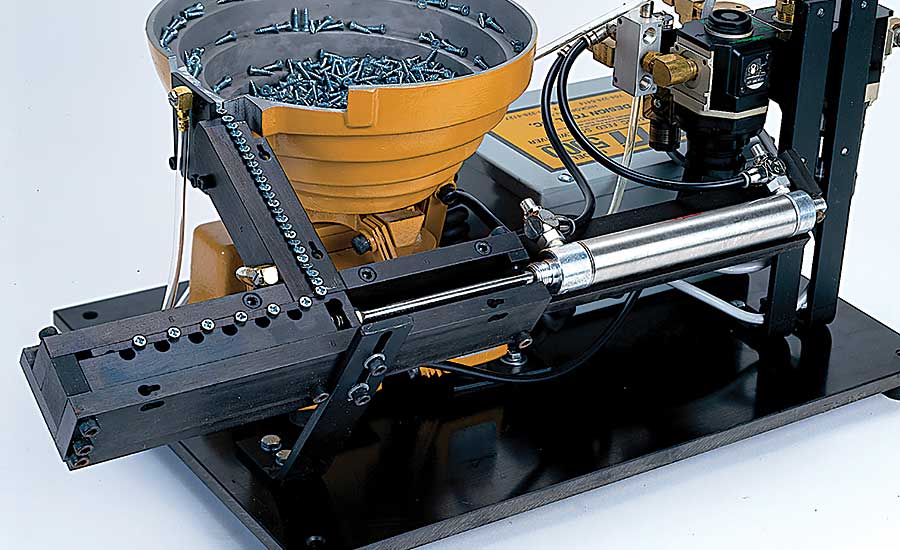

Feeding thread-cutting, thread-rolling and thread-forming screws is often a challenge, especially those with contoured heads and short lengths. Photo courtesy Design Tool Inc.

Movies and TV shows consistently promote lead characters who are able to complete their mission with little or no help from others. In the world of fastening, self-tapping screws fit this role better than any fastener, as they have the ability to create mating threads in metallic and nonmetallic base materials. By eliminating the tapping process, these fasteners (thread-cutting, thread-rolling and thread-forming screws) help manufacturers save money and increase production.

“The performance of self-tapping screws was much less important in the early 20th century, when thread-cutting screws were first introduced, than it is now,” explains Gene Simpson, vice president of quality and engineering at Semblex Corp. “Today’s thread designs provide manufacturers with high-performance joints in every application, including those that involve mating parts made of engineered plastics and light metals, like magnesium.”

Nidec America Corp., one of the world’s largest electric motor manufacturers, has benefitted from self-tapping and self-drilling fasteners for more than a decade. Earlier this century, Nidec engineers were faced with a challenge related to an assembly that involved joining an aluminum heat sink (stamped or extruded) to a thermal transfer pad with a proprietary rivet available from only one supplier worldwide.

Workers loaded the rivet into a mandrel, which was then installed in a special rivet gun. However, the gun required frequent maintenance, and the supplier would often take several weeks to repair and return the gun. Another negative was each rivet cost 11 cents.

Within a few months, Nidec management met with industrial-fastener-specialist Arnold Industries to discuss alternatives. Arnold recommended the use of a #5-40 Taptite II thread-rolling screw for several reasons. The fastener cost only 4 cents, cycle time was identical and installation required the use of a standard pneumatic screwdriver. In addition, the screw’s larger-diameter head provided greater and more uniform clamp load, and more efficient thermal transfer.

Thread-rolling, as well as thread-forming, screws have come a long way in a relatively short time, with OEMs increasingly using self-tapping and self-drilling versions of these fasteners since the early 1990s. One reason for this growth is that fastener suppliers have developed screws specifically for higher-performing plastics and metal. Equally important is the wide range of equipment that assemblers can use to properly install these fasteners. From handheld screwdrivers to automated systems, they always apply the proper torque to create perfect mating threads and tight joints.

Subtle (but Important) Distinctions

Thread-cutting, thread-rolling, and thread-forming screws have a similar composition. They are made of carbon or stainless steel or aluminum, and have tensile strengths of at least 100,000 psi, with relatively high torsional strengths. The screws can feature any drive head design and be used in a wide range of materials.

On each screw shank is an asymmetrical thread that produces opposing forces during installation to create mating threads. Because these threads match the dimensions of the installed screw, there is no play between the material and screw, resulting in a dynamically safe joint. Coarse and fine threads are available, with the former recommended for weak materials.

What differentiates these screws is how they treat the material. A thread-cutting screw has a shank slotted point that cuts the material and forms the thread as it is driven down, producing chips that fall out of the hole. The shank slot minimizes chip production. Some screws feature a drill-like fluted point that is designed to penetrate hard substrates.

These screws are often used in wood, metal and plastic products that need periodic maintenance, such as outdoor bench seating and power tools. For plastic applications, the screws perform best in thermoset materials having a flexural modulus from 500,000 to 2 million psi.

Thread-rolling screws were introduced in the 1960s as a non-chip alternative to thread-cutting screws for sheet-metal applications, according to Simpson. They have a tapered lead and require that the fastener be harder than the mating material. During installation, the fastener roll forms the mating material into the thread shape.

Manufacturers in many industries select these screws because they prevent cross-threading, resist vibration and are reusable. Another appeal is versatility. The screws can be used in aluminum, magnesium and plastic, as well as sheet metal, and some suppliers offer thread-rolling bolts.

Thread-forming screws create threads in a similar manner, although they tend to shape material more quickly and efficiently. These screws feature a blunt end, may or not require a preformed hole, and are generally used in sheet metal, plastic and composite parts that require high clamp loads to resist loosening. Some screws can be removed and reinstalled multiple times, or replaced with standard metric machine screws.

The biggest users of thread-forming screws are manufacturers in industries that use a lot of high-performance thermoplastics, such as electronics, automotive, agriculture and office equipment. In these applications, the material has a flexural modulus from 150,000 to 400,000 psi. White goods and furniture manufacturers also frequently use thread-forming screws.

Both the Rolok thread-rolling and Polyfast thread-forming screws from Semblex are available with and without a cutting edge. The Rolok thread features three asymmetrical lobes that form mating threads in the nut member. This design provides high performance through low drive torque and high strip-out torque in a wide range of materials and configurations, like c-shaped extrusions.

Polyfast screws have 45-degree asymmetrical threads, providing a narrow shank and a 26-degree point. The wide-angle thread slices cleanly through material with minimal material distortion and splitting, while the shank requires low installation torque and high strip out torque, and the point eases installation.

Aware of the increased use of carbon fiber reinforced plastic, EJOT has developed the FLOWpoint Delta PT thread-forming screw that requires no preformed hole. The screw’s thread features 30-degree flanks that produce high tensile strength, torsional strength and clamp loads, but little radial force, ensuring boss integrity. Available in steel, stainless steel, aluminum and titanium, the screw performs well under high-stress vibration conditions in plastic assemblies and allows for easy disassembly and reassembly.

Well-Equipped for any Challenge

In recent years, manufacturers have increased their use of thread-forming and thread-rolling screws because they effectively join dissimilar materials (such as steel and aluminum), eliminating the need for them to be spot-welded. Another reason for this shift is that these screws offer excellent joint performance in lightweight materials.

“With the increased use of newer materials comes the challenge of deciding whether to use thread-cutting or thread-forming fasteners for each application,” notes Jim Graham, president of Weber Screwdriving Systems. “Design engineers need to address four things to ensure proper fastener selection: material properties, joint type, required clamp load and serviceability of parts being joined.”

A common, but too-often ignored problem related to installing thread-forming screws in thermoplastic is plasticization or softening of the material. This is particularly applicable when installing fasteners with systems that run at 1,000 rpm and higher. Plasticization gives the appearance that a torque-controlled system is installing a screw correctly at, say, 20 in-lbs, but a phenomenon called joint relaxation can soon follow. Within a matter of seconds, minutes or hours, it can make initial torque in the joint fall off dramatically; sometimes by up to 50 percent (to 10 in-lbs net, in this example).

Graham says the problem of plasticization is equally challenging for value added molding companies that install screws into parts that are warm and just out of a mold. Aware of this, some manufacturers use fasteners with a double-helix (high-low) thread where the high thread is sharper than a conventional one. This design traps more material between the threads, increasing stripping torque and allowing for a lower prevailing torque during the driving process.

Sometimes it’s not easy to determine the installation problem related to thread-forming or thread-cutting screws. Cecil Morgan, applications engineer at DEPRAG Inc., cites a recent example of a major medical equipment manufacturer that was experiencing a high failure rate of stainless steel thread-forming fasteners used in aluminum parts. The problem was the screws were not fully seated, resulting in reworking the joints.

Initial testing revealed inconsistent friction torque levels. Some joints had a higher level than the specified tightening torque, while others only reached 40 percent of tightening torque. With further analysis, the manufacturer noticed slightly inconsistent hole diameters in the parts and inconsistent amounts of threadlocker on the fasteners.

To overcome these problems, the company began using DEPRAG’s Minimat EC stationary electric screwdrivers with the AST11 Controller. A software routine in the controller, the “Friction Torque Value Procedure,” calculates friction torque during fastener installation and applies consistent clamp load to the joint.

The company also offers the AST40 controller with Clamp Force Control (CFC) for its Minimat EC-Servo screwdrivers. CFC is an adaptive technology that eliminates all frictional influences up until the point of head seating, thereby ensuring the fastener provides consistent clamp force.

“Because these screws often require equal or greater torque for the thread rolling, forming or cutting operation than the final fastening torque, ensuring a secure joint can be difficult,” acknowledges Kevin Buckner, director of engineering at Design Tool Inc., which makes equipment that automatically feeds and drives all types of fasteners. “To overcome this problem, we often use DC screwdrivers equipped with transducers for these types of screws. DC drivers allow multiple tightening steps during screwdriving that verify thread cutting has been completed and that the final required torque value is within tolerance.”

Simpson says that feeding these screws is often a challenge, especially those with contoured heads and short lengths. His recommendation is to use designs with defined side walls, like pan-head screws, whenever possible. Another challenge is convincing customers of the need to focus more on total assembly cost than the component cost—as well as working closely with their fastener supplier throughout the entire fastener selection process, including joint design.

“The legacy fastener approach is too often put in place where we need to consider future cost savings, which isn’t the same as present cost avoidances,” explains Simpson. “Because a fastener has worked fine on many parts in the past, the company immediately wants to use it in new parts as well. But, what if the part is being installed in a new type of plastic they’ve just started using? Maybe a better option is available.”

Graham says screw reject rates and screw reusability are important factors to consider. The installation success rate for thread-forming screws is more than 99 percent, whereas for cutting screws it’s usually around 85 percent. This lower number is due to the possibility of cutting screws damaging parts at the final stages of manufacturing, which is quite expensive.

Regarding reusability, thread forming or rolling screws can be reused many times because they produce a high-quality thread during initial installation that ensures zero play within mating threads. Cutting screws, however, typically are used once or twice due to the possibility of them making another thread in the material each time they are installed. This may permanently damage the assembly, make it nonfunctional for its task or simply make it hard to remove the screw.

“Unlike thread rolling, thread cutting also produces contamination during the cutting phase, which is not always desirable,” notes Graham. “This is why cutting screws are not preferred for parts or assemblies that need to be opened occasionally for service or maintenance, such as the covers or enclosures of vacuum cleaners or other consumer products.”

By pairing Weber’s C30S advanced process controller with motor drive and transducer packages, engineers can install and verify thread-rolling and thread-cutting fasteners in core holes in injection moldings, castings, extrusions, and multimaterial stacks requiring from 0.01 to 60 newton-meters of torque.

The controller allows up to 31 different tightening recipes or strategies to be programmed to best accommodate any given joint configuration. Torque, angle, and native analog depth auditing is possible, and numerous communication or bus interfaces ensure compatibility with most plant communication and MES systems.

Frequently used with the C30S controller is the HET series of handheld electric screwdrivers that provide 0.1 to 30 newton-meters of torque. The screwdrivers can be used for installation and joint auditing, and they have the ability to log and graph joint data when installing and removing fasteners, for higher levels of quality control.

To ensure proper screw installation, Lori Logan, marketing manager at DEPRAG, says it’s essential for assemblers to use professional fastening tools rather than off-the-shelf pneumatic or electric screwdrivers. Equally important is performing regular testing, such as a joint analysis after driving the fastener to failure. This analysis creates a detailed torque graph, enabling assemblers to determine the exact torque levels at which the screw head is seated and the threads are stripped.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!