Handling High-Mix Harness Assembly

Organization, flexible equipment and standard work are the keys to handling high-mix production.

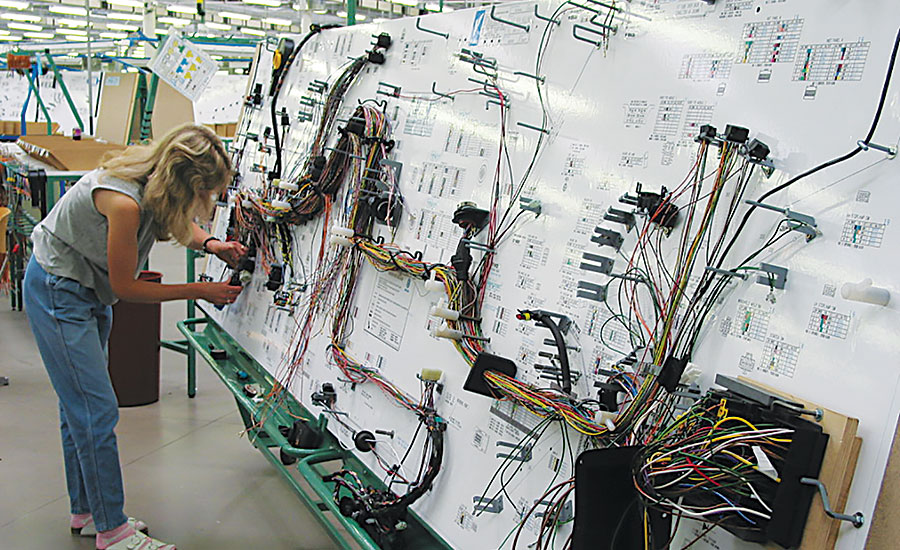

High-mix production is all about hewing to standard operating procedures. Photo courtesy Electri-Cord Manufacturing Co.

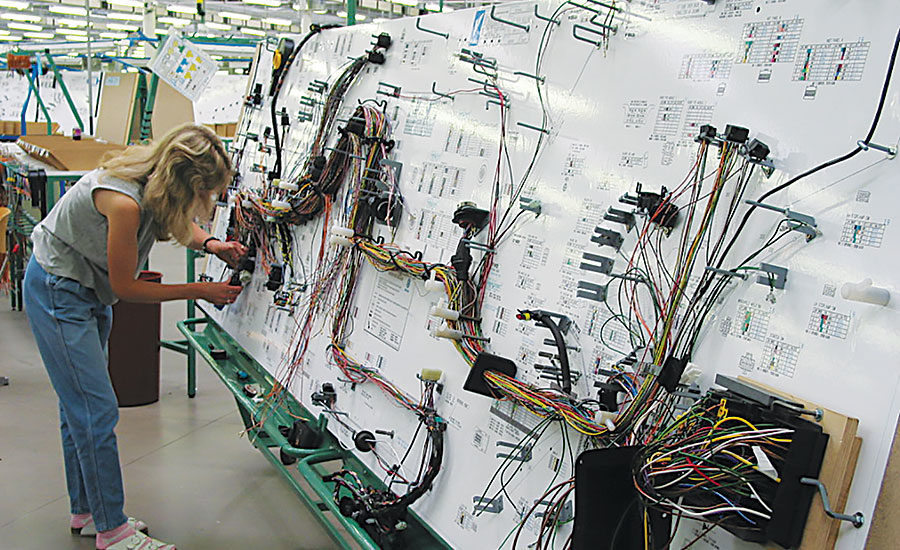

The biggest challenges of high-mix production are managing changeovers and maintaining consistency. Photo courtesy Aucotec AG

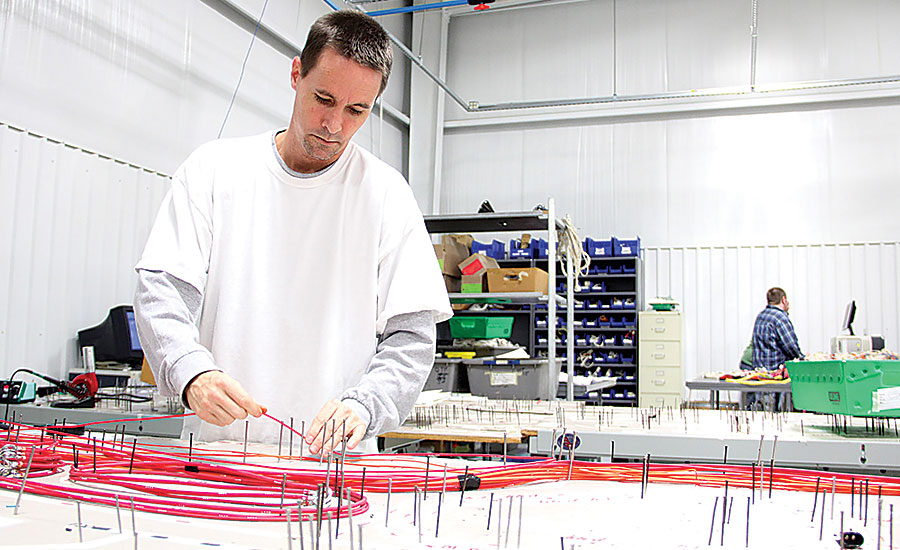

To minimize changeover time, engineers can try to combine like setups whenever possible. Photo courtesy Fero

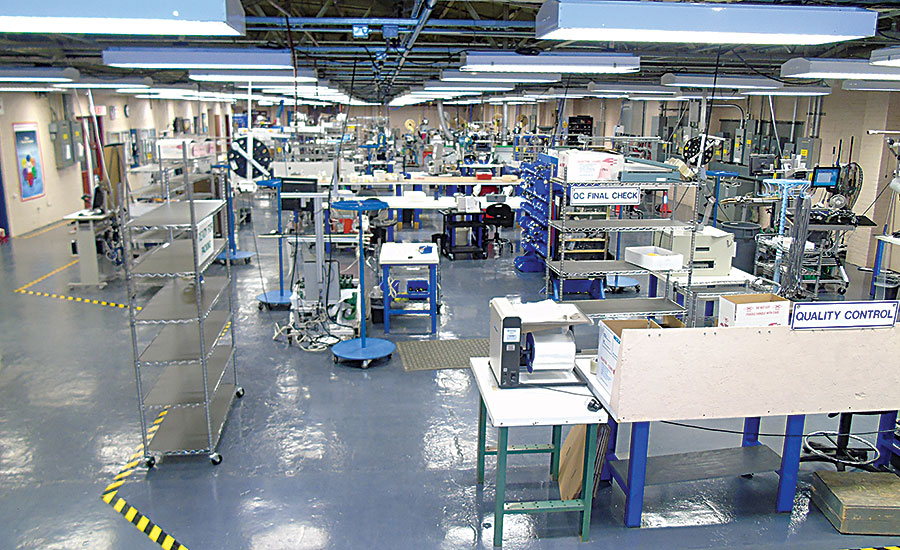

Enterprise resource planning software can help high-mix assemblers schedule jobs, batch setups and manage inventory. Photo courtesy SMC Manufacturing Services

When high-mix assemblers consider new equipment, they look for features to maximize flexibility, such as modular cutter blocks and quickchange applicators. Photo courtesy Schaefer Technologies LLC

Contract manufacturer Electronic Technologies International Inc. (ETI) has been in business for more than 25 years. With approximately 75 employees working in two shifts, the company provides printed circuit board (PCB) assembly, wire harness assembly and box build services at a 32,000-square-foot, ISO 9001 certified manufacturing facility in Fort Atkinson, WI.

“We’re definitely in the high-mix, low-volume realm,” says Ryan McCullough, director of sales and marketing at ETI.

The company has made assemblies for power generation and utility equipment, military and aerospace equipment, agricultural and construction equipment, medical devices, and industrial machinery. On the wire harness side of the business, the company can assemble anything from simple battery cables to complex control harnesses. The shop is equipped with high-speed, fully automated wire lead and cable processing machines, as well as a variety of semiautomatic benchtop equipment.

“We have customers that order three harnesses a year—but it’s a $5,000 harness for a large piece of capital equipment,” says McCullough. “And, we have customers that order 3,000 harnesses a week, but they’re simpler assemblies for the consumer market.”

High-mix production is a way of life at most harness assembly shops. Even operations that only serve a few high-volume automotive customers still have to cope with good deal of product variation. But, as product mix increases, so too, does the opportunity for inefficiency and production errors. Fortunately, with good shop-floor organization, wise technology choices, and a disciplined adherence to standard work, harness assemblers can handle high-mix production without compromising the bottom line.

High-Mix Challenges

The biggest challenges of high-mix production are managing changeovers and maintaining consistency.

“When you’re doing small jobs, sometimes the setup can be longer than the build time,” says Bill Surprenant, operations manager at AssembleTronics LLC, a contract manufacturer in Irving, TX.

The company produces cable assemblies, wire harnesses, electromechanical assemblies, control panels and compressor systems. On the harness and cable side of the business, AssembleTronics completes some 25 to 30 jobs per week in quantities from 10 to 100 pieces.

“We do a lot of work with customers looking for prototypes and quick-turn [jobs],” says Surprenant. “They want stuff in two to three weeks, so if it takes a week to get material, it puts some crunch on us to get it through the production floor.”

To manage that kind of variation, AssembleTronics depends on process documentation and industry standards, like IPC-WHMA-A-620 and SAE/AS9100C, the quality management system standard for aerospace manufacturing.

“Whether we’re building one piece or 10,000, it’s the same process,” says Surprenant.

T.R. Schilb agrees. The vice president of business development at contract manufacturer Electri-Cord Manufacturing Co. in Northborough, MA, Schilb says high-mix production is all about hewing to standard operating procedures.

“It’s all about following our process. It’s blocking and tackling. Making sure everything is documented,” he says.

At TCS Electronics Inc. in Farmington, NY, high-mix, low-volume is the norm. The ISO 9000 certified contract manufacturer assembles PCBs, cables and wire harnesses, and electromechanical products. The company also offers engineering and prototyping services.

“We run small jobs,” says Jeremy Jumper, manager of engineering and quality at TCS Electronics. “The last harness job we shipped was 100 pieces, and that’s pretty sizeable for us. Most of our jobs are 10 to 20 pieces.”

To minimize changeover time, engineers look to combine like setups whenever possible. The bills of material for orders are entered into a proprietary data base system that determines the most efficient order for production based on each day’s demand for various wires, terminals, tooling and setup parameters.

“Once we set a combination up, we want to run all of the opportunities requiring that combination before we switch over to something different,” explains Jumper. “We clearly spell out to assemblers the equipment, tools and documentation that they need, so they’re not searching for stuff. All the tooling and materials are readily available.

“Following their process documentation, assemblers will do a setup and then they’ll get their first pieces validated. That validation could be a crimp height measurement or a pull test—it all depends on the product and the workmanship class it’s being built to. Once that’s validated, they can run the job. Quality assurance personnel are readily available.”

To speed changeover on the lead-making equipment, TCS engineers load tooling and terminals on carts. While one job is running, a cart for the next job is set up.

“That way, the assembler just wheels the cart to the machine, swaps everything out, selects the correct program, and goes,” says Jumper.

At ETI, the shop floor is segregated by product type. Simple cables and harnesses are assembled in their own small, modular cell. Larger, more complex harnesses are assembled in another area with a skilled workforce.

ETI assigns highly trained “product experts” to shepherd complex projects from start to finish. These experts will be involved in the quote, the first build, and the production run. They are responsible for documenting the process and flagging potential problems.

“We’re an ISO-9001 certified facility, but there’s some tribal knowledge involved with wire harness manufacturing,” says McCullough. “You can follow the documentation, and it will get you there, but to get it done quickly and correctly requires tribal knowledge.

“I wish all my customers had perfect drawings, but a lot of times, you’ll find there’s a wire that’s an inch short. Our experts identify that sort of thing on the first build.”

To avoid mix-ups, ETI tries to minimize the amount of unfinished work on the shop floor. “For instance, an order won’t hit the floor, if inventory shows we’re a couple of pieces short,” McCullough says. “In addition, every order has a ‘traveler,’ a document in a very visible folder, that moves with the order from department to department, so you can tell where it is in the process.”

Gearing up for High Mix

Most high-mix shops have a mix of semiautomatic and fully automatic machines. Either way, flexibility, error-proofing and easy changeovers are key equipment characteristics.

“When we look at a machine, we want to see quick changeovers,” says McCullough. “We want to see modular tooling that allows us to go from 4/0 wire down to 20 gauge quickly without changing the guts of the machine. We’re looking for products that will help us reduce setup time and that are designed to be multifunctional.”

For example, ETI is considering investing in flexible, reusable harness layout boards that can be reconfigured quickly and that guide assemblers as they route wires from connector to connector.

“When you’re dealing with high-mix assembly—in this industry especially—it comes down to your labor costs,” adds McCullough.

Jumper agrees. “Whenever we look at equipment, we look for features that will maximize flexibility—things like modular cutter blocks and quick-change applicators,” he says. “We want equipment capable of processing the widest range of wires and terminals. We’re always looking for fast setup and changeover and quality controls.

“For example, our lead maker has built in crimp height and force monitoring, as well as length encoding, so we know the wires coming out of there are the right length, have the right terminals on them, and are crimped to the right specs. That way, we don’t have to spend as much time on inspection. It’s much more of a closed-loop process.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!