Leak Testing Auto Parts

The latest automotive systems require innovative leak test methods and fixturing.

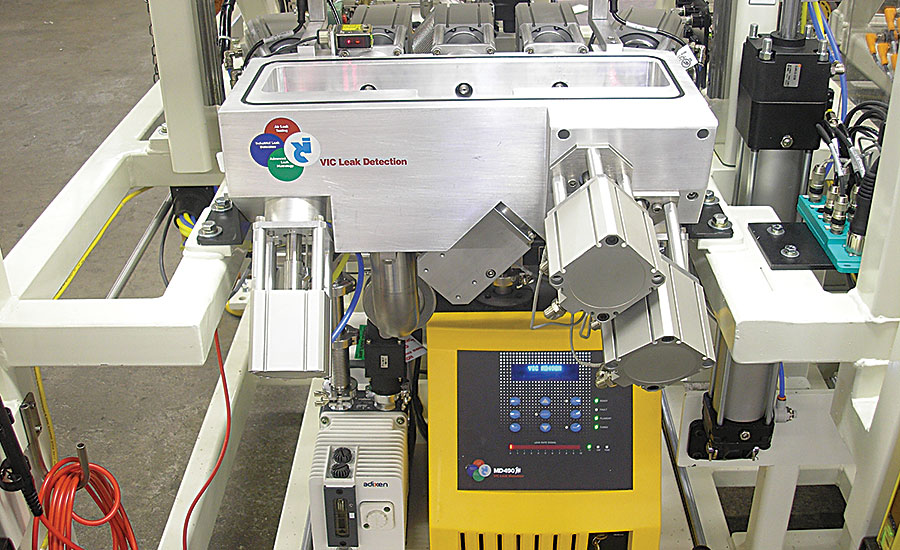

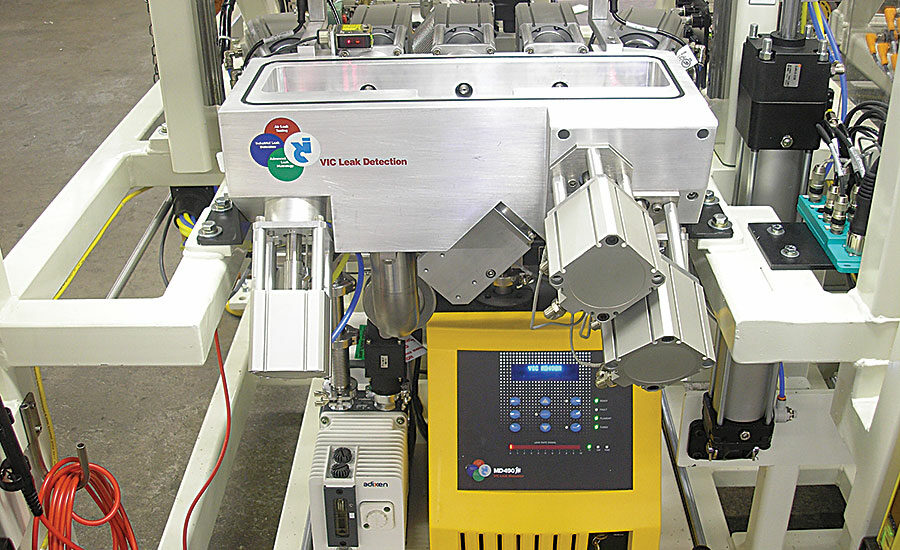

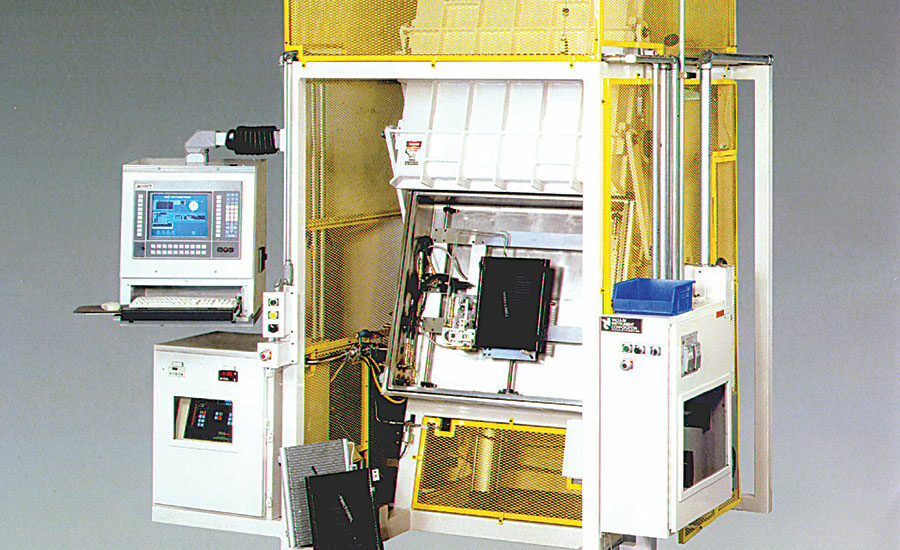

This leak test system for fuel rails includes a hard-vacuum test chamber, vacuum pump and helium mass spectrometer. Photo courtesy Vacuum Instrument Corp.

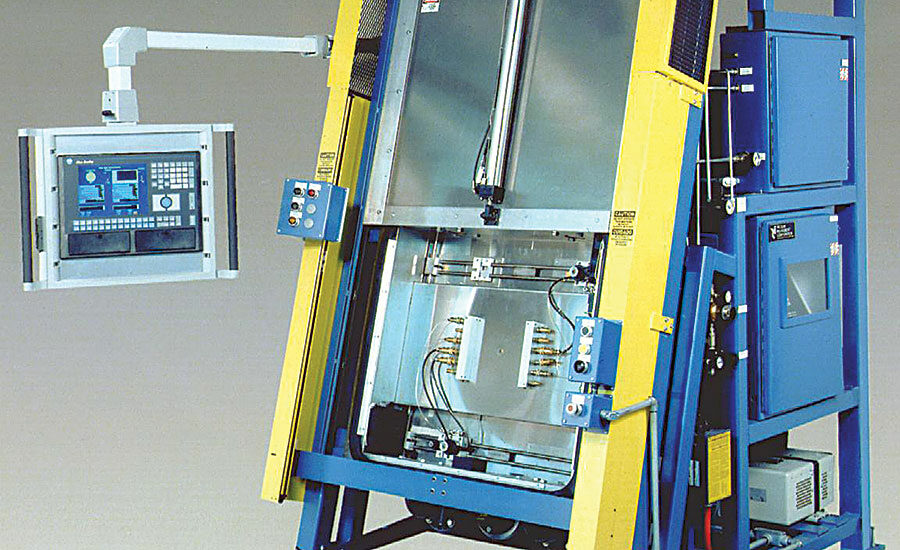

High-pressure, direct-injection fuel rails have a leak rate spec of 10-4 atmospheric cubic centimeters per second. Photo courtesy Vacuum Instrument Corp.

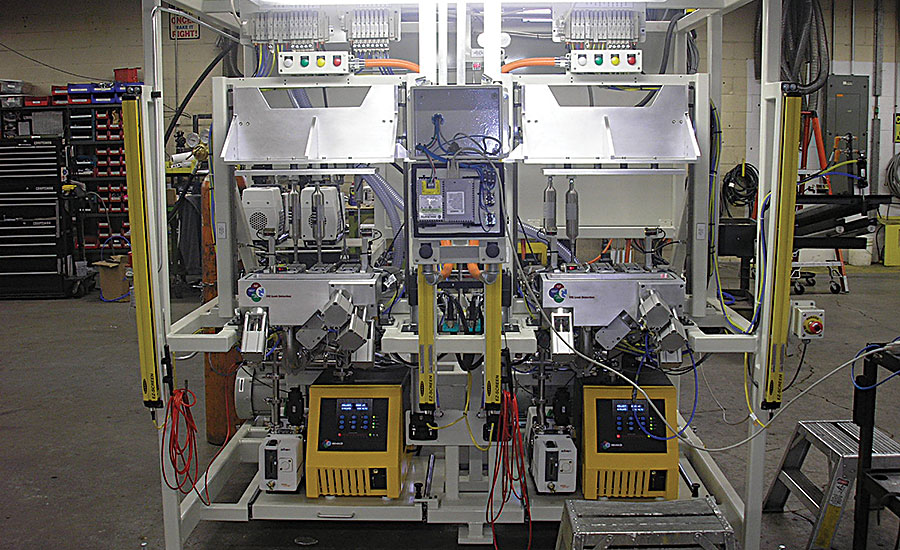

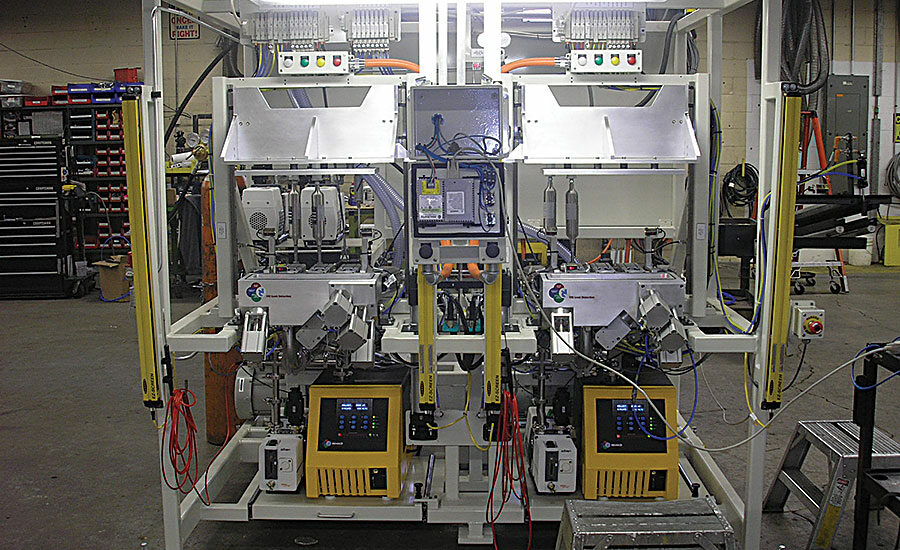

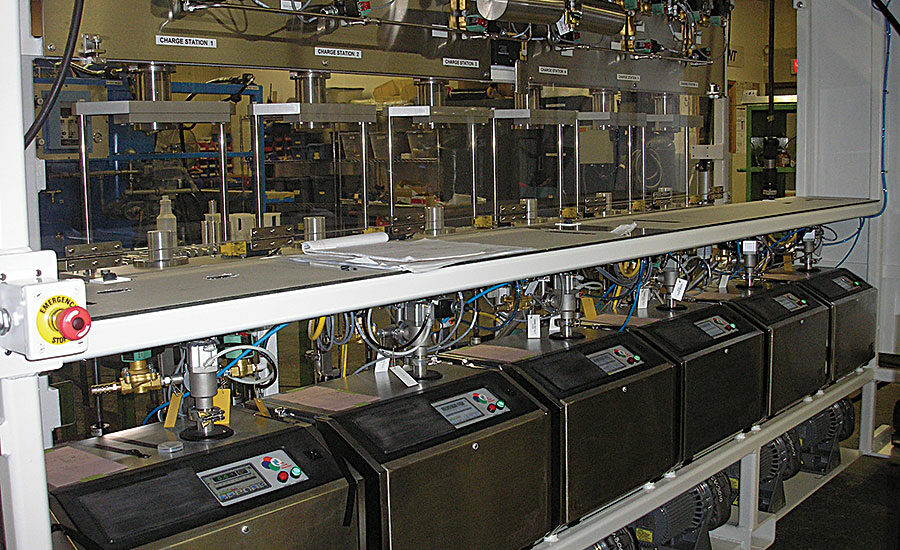

This six-station, hard-vacuum system was built to check lithium-ion batteries for leaks. Photo courtesy Vacuum Instrument Corp.

An air-conditioner condenser is in position to be leak-tested in a helium hard-vacuum system. Photo courtesy Vacuum Instrument Corp.

An operator loads an air-conditioner condenser into a hard-vacuum test chamber. Photo courtesy Vacuum Instrument Corp.

In the accumulation test method, helium escaping the part is allowed to accumulate in an enclosure that surrounds the part at atmospheric pressure. The accumulated helium is then mixed and sampled by a mass spectrometer. Photo courtesy Vacuum Instrument Corp.

Implementing a leak test system is much easier if engineers begin thinking about testing before the rest of the assembly process is in place. Photo courtesy Vacuum Instrument Corp.

Fixturing is critical for accurate leak testing. This fixture was built for high-pressure fuel rails. Photo courtesy Vacuum Instrument Corp.

In the past, automobile manufacturers only required basic forms of leak testing to check standard subassemblies, such as, air conditioning, power train and cooling system components. Traditional hard-vacuum and accumulation methods were—and still are—used to test components such as radiators, evaporators, condensers, air-conditioner hoses, torque converters and valve bodies.

However, test requirements for today’s automobiles are a little different. With advances in fuel delivery technology, engine monitoring and even power sources, the need for innovative leak detection techniques has become essential.

High-Pressure Fuel Rails

High-pressure, direct-injection fuel rails have a leak rate spec of 10-4 atmospheric cubic centimeters per second (atm-cc/sec). Leak testing these parts with helium in a vacuum chamber is a complex process.

A fuel rail is essentially a tube (usually resembling a rail) to deliver gasoline to individual fuel injectors in an internal combustion engine. In the past, vehicle manufacturers designed fuel rails to withstand pressures of only 30 to 60 psig, a minimum requirement for port injection.

Now, to meet more stringent standards for fuel economy and efficiency, fuel rails have been redesigned to withstand much higher pressures—up to 5,000 psig and beyond. Greater test pressures mean greater helium usage, warranting the need for a helium recovery system.

Leak Testing Batteries

Whether it’s in response to soaring gas prices or global warming, more and more people are looking into fuel-efficient, cleaner-running cars, such as hybrid electric vehicles and fully electric vehicles.

Lithium-ion batteries play a key role in these vehicles, having the greatest charge capacity over competing battery technologies. Just like with fuel rails, these batteries are tested with a helium hard-vacuum system.

Each chamber is provided with its own product evacuation, charging, venting and valve scheme. A common dry vacuum pump with vacuum ballast provides the vacuum source. During the initial chamber evacuation, the system will perform a fitting-in-place check using a pressure transducer. This check is a pretest of seal integrity prior to evacuating the product and charging it with helium. After a successful vacuum decay test, the part is back-filled with helium to a specified pressure. After completion of all tests, the test part is vented to atmospheric pressure and re-evacuated to remove all residual helium before the part is unloaded.

Helium Hard-Vacuum Test Method

The hard-vacuum method can detect leaks as small as 1 x 10-9 atm-cc/sec. Any leaks in the test part can be measured from the inside-out or outside-in.

For inside-out leak detection, the test part can be filled with helium and sealed; it can be “bombed” with helium after it is sealed; or it can be pressurized with helium during the actual test. Then, the part is placed in a vacuum chamber; the chamber is evacuated; and the test instrument (a mass spectrometer) looks for helium escaping from the part into the chamber.

For outside-in leak detection, the test part is evacuated and connected to the mass spectrometer. Then, helium is sprayed around suspected areas outside of the part. If the part has a leak, helium will be drawn into the test part and be detected by the mass spectrometer.

The inside-out method with a vacuum chamber has some advantages. A sniffer is not used. Testing is automatic and not dependent on the operator. The sensitivity achievable with this test is very high.

Even with these advantages, however, cost is a consideration with the vacuum chamber inside-out method. While the sniffing test requires only the leak detector and the ability of the operator, the hard-vacuum test requires more complex and expensive equipment.

Ultimately, the best method to use comes down to the application. The hard-vacuum method vastly reduces the incidence of human error, which makes it appealing in many industrial applications. The sniffing test is better for maintenance applications and for identifying the location of leaks in defective parts.

Production rates vary with the hard-vacuum test method. Rates range from 100 parts per hour to more than 700 parts per hour, depending on the configuration of the system (single chamber, dual independent chambers, dual alternating chambers, or even multiple test stations).

Systems differ in complexity, from manual loading and unloading by an operator to automatic loading and unloading with a robot. Depending upon the size and weight of the test part, various cranes might even be used to load and unload parts.

Some systems include modular vacuum chambers with wheels and quick connects for ease of changeover. In addition, some models even provide a charge-head tooling feature for changeover to accommodate various test part shapes, sizes, and configurations.

Battery-Powered Electric Vehicles

Lithium-ion batteries aren’t the only part of an electric vehicle that gets checked for leaks. The compartments where these batteries are stored are also tested for leaks. For example, one electric vehicle manufacturer specifies the leak rate for battery storage compartments at 9 standard cubic centimeters per minute at 0.5 psig using 10 percent helium in an atmospheric accumulation test system.

The accumulation method is comparable to a sniffing leak test. Helium escaping the test part is allowed to accumulate in an enclosure that surrounds the part at atmospheric pressure. The accumulated helium is then mixed and sampled by a mass spectrometer.

The accumulation test has advantages in that it does not require expensive vacuum chambers or vacuum pumps. It also tests for overall part leakage, unlike the sniffing method. This test method can detect leaks as small as 1 x 10-5 atm-cc/sec, depending on the size of the part and requisite cycle time.

As with the hard-vacuum method, production rates vary with the helium accumulation method, from 25 seconds per part to 600 parts per seven-hour shift, depending on the configuration of the system (single chamber, dual chamber, etc.). And, as with the hard-vacuum method, parts can be loaded and unloaded manually or robotically, depending upon the size and weight of the test part. Automatic tooling features are also available to facilitate connection and sealing.

For testing automotive radiators, the chamber is typically box-shaped, with a pair of gear-driven, vertically mounted, double-tooled stainless steel doors. Torque converters require a bell-type, stainless steel upper chamber.

Traceability

All leak test systems employ a programmable logic controller (PLC), which records all test records and data. The PLC is equipped with a USB port to which the operator can connect a computer or flash drive to download and record data.

In some cases, an auto-calibration sequence is used to establish background and calibration scale factors. It also provides variable leak rate data for each part tested. Upon conclusion of the leak test, results will be available for transmission to the customer’s data acquisition system.

The system can record and store variable leak test data, such as leak rate, cycle time and test-part pressure. Also, the system can have user-programmable intervals for calibration routines based on the total number of machine cycles or specific times during a given work shift. Ethernet communication of test results can be provided for integration with a customer’s bar code data acquisition system.

Fixturing for Leak Testing

Fixturing is often the weak link in any leak-test system. In many instances, when a customer believes a leak detector is not working, the true culprit lies elsewhere in the process.

Implementing a leak test system is a lot easier if manufacturing engineers begin thinking about how they are going to test for leaks before the rest of the assembly process is in place.

Many assemblers are surprised to find that the same pallets and fixturing they use to build their products may not work when it comes time to perform their leak-testing operations. But, the requirements of, say, an automotive exhaust system test stand are much different than those of a helium-based, multi-site hard-vacuum leak detection system.

There’s no doubt that leak detection criteria is getting more complex. However, thanks to innovative developments in test-system design, automotive component manufacturers can meet tighter leak-rate specifications.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!