Rules for Routing Aircraft Wiring

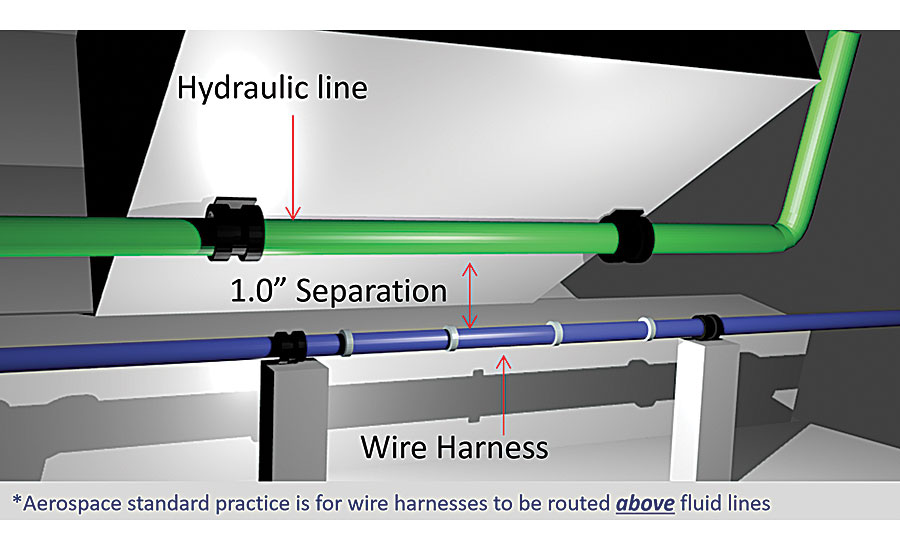

Figure 1 This figure shows a wiring harness routed near a pressurized hydraulic line. Federal regulations require a safe distance between the harness and the line. Illustration courtesy Lectromec

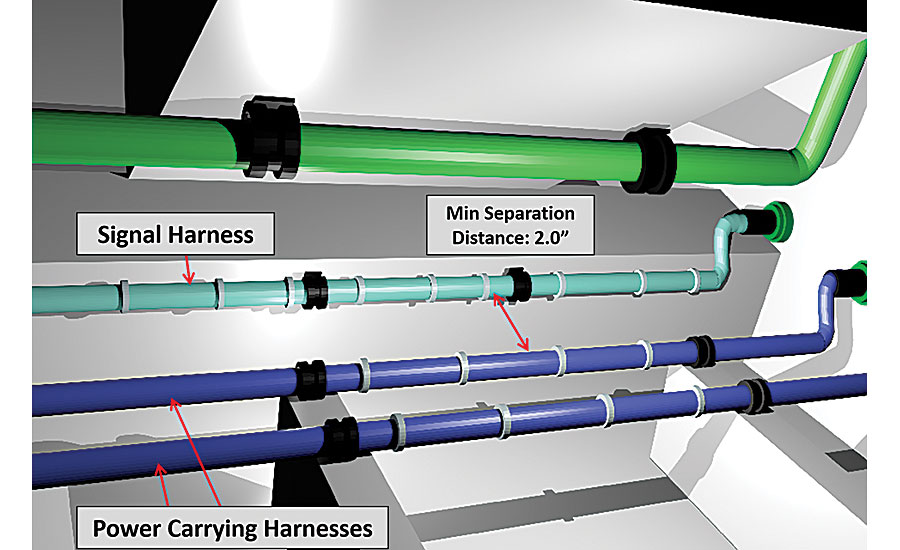

Figure 2 The signal harness (cyan) is within 2 inches of the closest power-carrying harness (blue). Our analysis found that the power cables produced no EMI on the shielded cables in the signal harness. Illustration courtesy Lectromec

Figure 3 Arcing from a cable can adversely affect nearby components. Here, arcing from a breach in the wiring insulation would likely start at the clamps. Illustration courtesy Lectromec

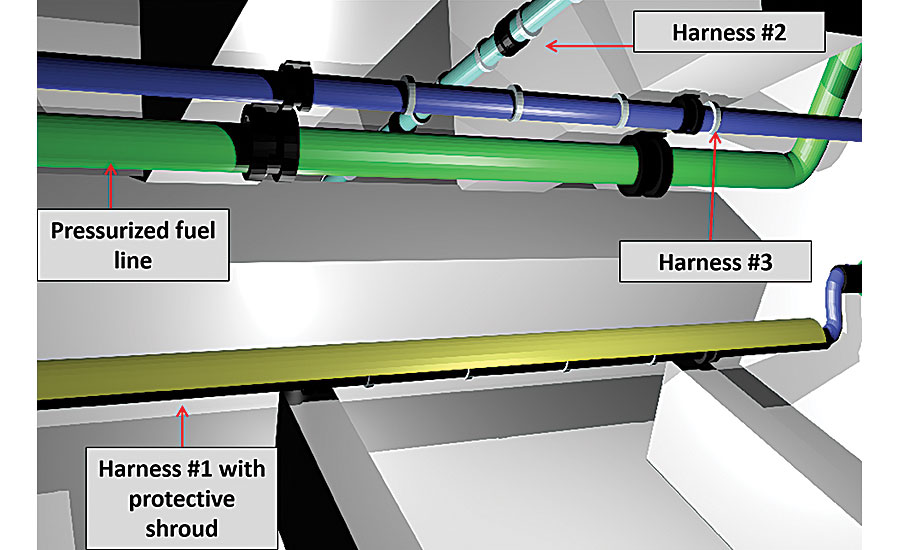

Figure 4 In this example, three wire harnesses are routed near a fuel line. Harness 1 is routed beneath the line, but it is protected by a shroud. Harness 2 is routed above and perpendicular to the fuel line, but the supporting clamps are too far apart to prevent sagging and chaffing on the tube. Harness 3 is routed horizontally, parallel to the line, which is not an issue. However, the separation distance is less than the allowed distance as defined by a damage assessment. Illustration courtesy Lectromec

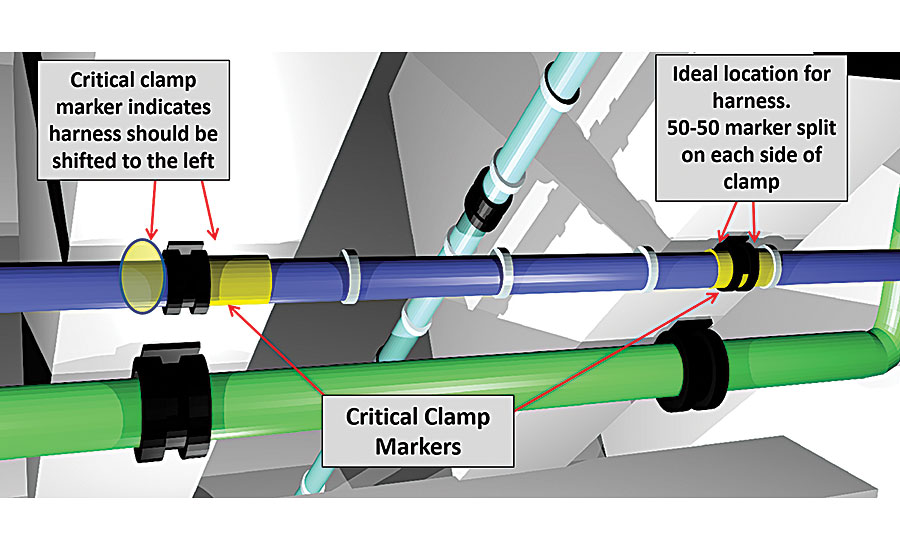

Figure 5 Critical clamp markers indicate where a clamp should be placed on a harness. They provide a quick visual reference to a maintenance technician if there is a misalignment of a harness or a harness has slid from its designed location. Illustration courtesy Lectromec

The performance of an aerospace wiring harness depends as much on its location in the overall assembly as it does on the wires themselves. Photo courtesy ELFON Ltd.

Heat from nearby components can adversely affect the performance of an aerospace wiring harness. Photo courtesy Co-Operative Industries Aerospace & Defense

In the late 1980s, a series of accidents and incidents raised concerns about the safety of electrical wiring in aircraft. Investigations found several common factors that could degrade the electrical wiring interconnection system (EWIS) of an airplane over time.

In response, the Federal Aviation Administration (FAA) issued the 25.1700 series of regulations covering the design, manufacture and routing of aircraft wiring.

One of the regulations, 25.1707, provides ten guidelines for routing and manufacturing electrical wiring so that it’s not adversely affected or damaged by fluid lines, mechanical cables and other electrical wiring. This article will review each of those guidelines, provide options for compliance, and discuss factors that will affect maintenance.

Damage Assessment

Regulation 25.1707 starts with the following: “Each EWIS must be designed and installed with adequate physical separation from other EWIS and airplane systems so that a EWIS component failure will not create a hazardous condition. …Adequate physical separation must be achieved by [an acceptable] distance or by a barrier that provides protection equivalent to that…distance.”

In other words, a hydraulic line should be located far enough away from a wiring harness, so that if the line were to rupture, the harness would not be damaged. Similarly, the harness should be sufficiently far from the hydraulic line so that, if electrical arcing should escape from the harness, the line would not be damaged. If the space between the line and harness can’t be increased, then one or the other should get additional protection.

What are the criteria for determining an acceptable separation distance? To address that, it’s helpful to look at an example. Figure 1 shows a wiring harness routed near a pressurized hydraulic line. The CAD model shows the harness 1 inch from the line. The harness contains four wires: two 16 AWG wires on 15-amp thermal circuit breakers and two 20 AWG wires on 7.5-amp thermal circuit breakers. The wires carry power in different phases.

There are two ways to determine if there might be an issue: physical testing or simulation.

For physical testing, engineers should strive to match system parameters and define safety thresholds, such as the maximum temperature of the hydraulic line. There are many variables to consider, including operating temperature, maximum fluid pressure and minimum tube thickness. An experienced laboratory can be a great resource for performing such tests and providing posttest analysis.

Simulation can be used to supplement test data, or it can be used as a standalone assessment process. With simulation, it’s possible to assess separation distance for a variety of materials. For example, engineers could determine if the hydraulic line would be more susceptible to failure if it’s made from aluminum or composite materials.

Lectromec’s arc damage modeling tool can be used to simulate wire failures and assess the potential for damage to nearby harnesses, structures, fuel lines and hydraulic lines.

The results of tests and simulations should provide a clear indication of a safe separation distance. If the test results are inconclusive (the target was near a failure condition, but did not actually fail), then additional testing should be performed. Alternatively, engineers may act empirically, either increasing the separation distance or adding a protective barrier.

Electromagnetic Interference Compliance

The next section from 25.1707 focuses on electromagnetic interference (EMI). It states: “Each EWIS must be designed and installed so that any electrical interference likely to be present in the airplane will not result in hazardous effects upon the airplane or its systems.”

According to the FAA’s guidance document on this regulation, engineers should look at the following sources of EMI:

- Electrical noise generated from equipment connected to the bus bars.

- Electrical coupling or cross-talk between electrical cables.

- Electrical coupling between cables and aerial feeders.

- Electrical equipment operating out of spec or malfunctions generating EMI.

- Parasitic eddy currents and voltages in the EWIS and grounding systems.

- Lightning currents.

- Static discharge.

Dissimilar frequencies between the electrical generation system and other systems.

Figure 2 shows three harnesses. Two are power-carrying harnesses (blue), and the other is a signal harness (cyan). The signal harness is within 2 inches of the closest power-carrying harness. In this design, the interference from the power cables was investigated and determined to have no effect on the shielded cables in the signal harness.

However, if the cable shielding was insufficient to protect the signals, then additional methods for protection would need to be considered. Engineers would have to increase the separation distance or add shielding to the cables.

Systems that are necessary for continued safe flight, landing, and egress should be given the highest priority when assessing the impact of EMI.

The following methods are commonly used in the aerospace industry to protect against EMI:

- Use of EMI or electromagnetic pulse filter protection connectors.

- Route power and signal wires through separate connectors, if possible.

Shielded cables should be considered for signal cables. Safety-critical systems that depend on clean signals may need this type of shielding for additional noise reduction. When selecting a shielded construction, engineers should ensure that the EMI range suppressed by the cable is enough to protect the wire’s signal.

There are harness protection schemes that offer EMI shielding. As with other shielding techniques, it is important to determine the shield grounding before considering this option.

Separate the power wires from the signal harnesses. This design choice may not be possible in some scenarios, particularly where space is limited.

Heavy-Current Cables

The next section of 25.1707 covers the need to physically separate heavy-current cables from other components. The regulation states: “Wires and cables carrying heavy current, and their associated EWIS components, must be designed and installed to ensure adequate physical separation and electrical isolation so that damage to circuits associated with essential functions will be minimized under fault conditions.”

If testing is necessary, there are a couple of important considerations.

First, are you looking to solve for a particular case or the general? Solving for a particular case can be advantageous for several reasons, but the two most important are cost and compliance. The reason for this is that solving for the general case can require a broad test matrix to address many configurations (physical, electrical and environmental). Furthermore, with regard to compliance and aircraft design, testing for a general case may create recommendations for a boundary that are too large for a given area and are more severe than the particular case.

The other major consideration is what’s in the surrounding area. Consideration of damage to nearby equipment is important. With regard to assessing potential damage to nearby wiring components, these assessments will likely result in separation distances greater than those identified for equipment.

In our earlier example, the minimum distance between a signal cable and a power cable was 2 inches. The heavy power cables include three 4 AWG wires with three different phases. In practice, it is most likely that a breach and arcing would start at the clamps (see Figure 3).

While a general case would examine the 4 AWG cables under various conditions, the particular case will examine the potential damage to the jacketed, shielded, twisted-pair in the signal harness. The signal cable was selected because, based on past assessments, it was deemed to be the most susceptible to arcing damage.

The test results should determine if the arc damage adversely affects the airworthiness of the EWIS. In particular, the following questions must be answered:

- Is the separation sufficient?

- If the separation is sufficient, what is the margin of safety?

- If the separation is not sufficient, what can be done to make the configuration safe?

If additional segregation materials are used, that should be included in the “Instructions for Continued Airworthiness” maintenance document.

Grounding and Power Separation

The fourth section of 25.1707 covers grounding and power separation. It states: “Each EWIS associated with independent airplane power sources or power sources connected in combination must be designed and installed to ensure adequate physical separation and electrical isolation so that a fault in any one airplane power source EWIS will not adversely affect any other independent power sources.

“In addition:

Airplane independent electrical power sources must not share a common ground terminating location.

Airplane system static grounds must not share a common ground terminating location with any of the airplane’s independent electrical power sources.”

To be clear, the “independent airplane power source” is the “general source of power for the whole of the airplane.” This includes the engines, generators driven by the auxiliary power unit, and batteries.

The first bullet point is fairly straightforward. The objective was to ensure that the generating system EWIS components are assessed and examined in the same way as all other EWIS components. In particular, this requires the consideration of power routing through the aircraft and the physical proximity. System components that require multiple input power sources for the purposes of redundancy require special consideration.

Handling of the isolation of separate aircraft power must be considered from a physical and functional aspect. From the physical side, this is addressed by common cause analysis and, if routed in close proximity, potential damage assessment. From the functional viewpoint, the failure of one power source should not adversely affect other power sources.

The regulation on ground terminations is also straightforward. By separating grounding locations for different power systems, the failure of a single grounding point will not damage or disable multiple power sources. Furthermore, by physically separating the grounds, reducing or eliminating interference in the electrical system becomes easier.

For additional information on electrical grounding and bonding requirements, consult aerospace standard AS50881 and aerospace recommended practice ARP1870A from SAE International.

Component Separation Guidance

The next few sections of 25.1707 state: “Except to the extent necessary to provide electrical connection to the fuel/hydraulic/oxygen/water/waste systems components, the EWIS must be designed and installed with adequate physical separation from fuel/hydraulic/oxygen/water/waste lines and other fuel/hydraulic/oxygen/water/waste system components, so that:

An EWIS component failure will not create a hazardous condition.

Any fluid leakage onto EWIS components will not create a hazardous condition.”

To understand the consequences of EWIS component failure, we only have to look back at the loss of a U.S. Air Force F-22 on Nov. 15, 2012. The cause of the crash was revealed to be a chafed generator wire that arced, burned through an adjacent hydraulic line, and caused the generator to go off-line. When the pilot attempted to restart the generator, the ensuing arc ignited the misting hydraulic fluid and started a fire in the jet’s left accessory-drive bay. The fire compromised critical electrical and hydraulic systems that control the flight control surfaces. The pilot ejected safely, but the aircraft was destroyed.

What does this mean from a certification perspective? First, safe separation distances must be defined for all of an aircraft’s fluid-carrying system components. Not all tubes are going to fail under the same conditions. Second, EWIS components should be installed so that they are above fluid- and oxygen-carrying components; this will help to minimize the likelihood of fluid contamination of the EWIS.

In Figure 4, three wire harnesses are routed near a fuel line. Harness 1 is routed beneath the fuel line, but it is protected by a shroud. While this can be used to protect a harness from fluid exposure, it does add weight, and it may need to be checked periodically during airworthiness inspections.

Harness 2 is routed above and perpendicular to the fuel line, but the supporting clamps are too far apart to prevent sagging and chaffing on the tube. Additional clamping could be installed to resolve this issue.

Harness 3 is routed horizontally, parallel to the line, which is not an issue. However, the separation distance is less than the allowed distance as defined by a damage assessment. Redesign, separation or protective sleeves must be considered for harness 3.

This part of the 25.1707 regulation should also be considered in coordination with the recommended practices of AS50881 section 3.11.11 “Gas- and Fluid-Carrying Lines and Tubes.” Whereas the standard suggests that wiring should be routed with “the maximum practicable separation from all fluid-carrying lines,” this regulation allows wiring to be installed in close proximity as long as the failure consequences have been considered.

The support clamps for separation between the EWIS and fluid and oxygen lines should be given additional consideration. AS50881 suggests that supporting clamps for EWIS should not be connected to fluid and oxygen components unless the separation is less than 2 inches.

The AS50881 standard recommends that wiring should “be installed to maintain positive separation [from gas- and fluid-carrying lines and tubes] of at least 0.5 inch.” First, while this separation distance may be fine for some system configurations, it is not an acceptable blanket statement for separation. Lectromec has performed testing to show that tube failure can occur at an even greater distance from the arc plume generated during a wire failure event.

Second, conformity to the regulation takes precedence over industry guidance. Certification relies on data to verify the safety of a design, and the recommendations of AS50881 do not provide sufficient data to support certification.

Control Cable Separation

The eighth section of 25.1707 focuses on separating EWIS from control cables. It states:

“EWIS must be designed and installed with adequate physical separation between the EWIS and flight or other mechanical control systems cables and associated system components, so that:

- Chafing, jamming or other interference are prevented.

- An EWIS component failure will not create a hazardous condition.

Failure of any flight or other mechanical control systems cables or systems components will not damage the EWIS and create a hazardous condition.”

This requirement poses a separate set of challenges. Clearly, moving cables can create a hazardous situation with EWIS, because they can quickly abrade protective insulation. Obvious failure conditions include:

- Electrical arcing that damages or destroys all wires in the cable.

- Damage and loss of functionality of a flight control cable.

- Damage to nearby systems due to arc plume or ejected molten materials.

A popular trend in the EWIS community is the critical clamp marker (see figure 5). These markers indicate where a clamp should be placed on the harness. This provides a quick visual reference to a maintenance technician if there is a misalignment of a harness or a harness has slid from its designed location.

While not necessary, it is recommended that these markers be added to EWIS harnesses in areas with mechanical cables. This will ease inspections and ensure EWIS components that moved during maintenance are reinstalled with the proper clearance.

An additional consideration with the mechanical cables is the jamming of mechanical components, such as a harness jamming a pulley. Cables should have sufficient clamping to prevent this from occurring. In particular, the clamping and EWIS harness support must be designed to prevent a hazardous condition from occurring with the loss of a single clamp. These clamps should be inspected regularly.

The failure of a control cable could adversely affect any EWIS component and create a hazardous condition. Mechanical cable routing and protection mechanisms should be considered in these areas.

Common cause analysis must be done to ensure that the loss of a mechanical cable will not damage an EWIS component that supports a secondary or redundant system.

Heated Equipment Separation

The last section of 25.1707 covers heated equipment. It states: “EWIS must be designed and installed with adequate physical separation between the EWIS components and heated equipment, hot air ducts and lines, so that:

An EWIS component failure will not create a hazardous condition.

Any hot air leakage or heat [applied to] EWIS components will not create a hazardous condition.”

Important aspects to be considered include:

- The heat generated by the local equipment and air ducts.

- The ambient temperature of the zone.

- The heat generated by the harness itself.

Nearby equipment and air ducts may radiate heat that can affect EWIS components. Although the wires may be rated to 150 C or more, supporting components, such as splices, heat-shrink tubing, clamps and sleeves may not be rated to the same temperature.

Local environmental conditions can also affect the harness. Prolonged exposure to heat can degrade performance.

And, while it may seem obvious, it’s important to consider the resistive heating of the wires. A means for estimating a harness’s rated current-carrying capacity (or ampacity) is included in AS50881. The formula is a good way to estimate the maximum current harness wires can carry without exceeding the wires’ rated temperature.

This formula can also be used to account for heating in nearby systems. For example, suppose we have a harness that is rated to 150 C (based on the wire specification). The ambient temperature in the zone during flight is 50 C, which leaves a potential for a 100 C increase during operation. Using the formulas and charts, we find that the ampacity is approximately 40 amps.

Furthermore, suppose this harness is routed near a hot air duct. Testing has shown that the radiant heat will increase the surface temperature of the harness by 20 C. After recalculation, the harness ampacity drops by 10 percent to 36 amps. Based on these calculations, engineers may need to use larger gauge wires, reroute the wires, or add a protective sleeve.

Compliance for Your Organization

The safe and reliable operation of an EWIS is more than just the wires in the harness: It also requires consideration of the nearby systems. Lectromec can help you meet FAA certification requirements by identifying and addressing wiring separation issues. Our systematic analysis starts with understanding the particular needs of your project and working to define tests and parameters to cover both your design and regulatory requirements.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!