Automation and Lean Help Magna Stay Flexible

Magna T.E.A.M. Systems uses automated guided carts to improve flexibility on its assembly line in Toledo, OH. Photo by Austin Weber

Magna Toledo assembles front-end modules for the Jeep Wrangler. Photo courtesy FCA

Magna Toledo assembles front-end modules for the Jeep Cherokee. Photo courtesy FCA

Assemblers use DC electric tools to ensure product quality. Photo by Austin Weber

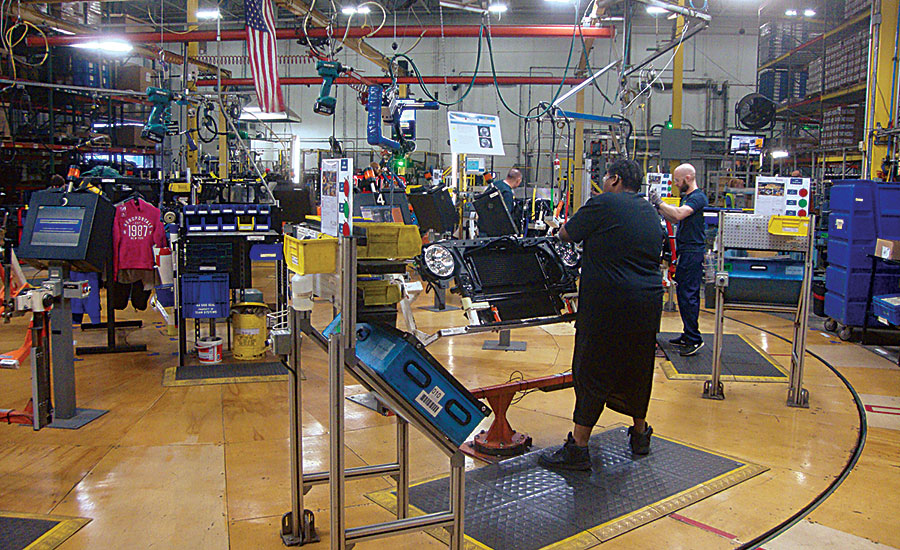

An eight-position carousel is used to assemble front-end modules for the Jeep Wrangler. Photo by Austin Weber

A key tool in Magna T.E.A.M. Systems’ lean manufacturing effort is a series of P.R.I.D.E. boards located in all corners of the plant. Photo by Austin Weber

Parts kitting (blue tote) ensures that assemblers get the right part at the right time at the right workstation. Photo by Austin Weber

Magna T.E.A.M. Systems operates four assembly lines at its Toledo plant. Photo by Austin Weber

An error-proofing station uses seven cameras to confirm that parts are sequenced correctly. Photo by Austin Weber

Front-end modules are robotically loaded onto semitrailers in the sequence that they will be unloaded and used at the Jeep assembly plant. Photo by Austin Weber

Front-end modules are multipiece assemblies that integrate a number of components, such as bumpers, engine cooling modules, headlamps and wiring harnesses. Photo courtesy FCA

If cars and trucks had a “face,” it would be the front-end module and fascia system. The subassemblies comprise everything on a vehicle from the bumper to the front of the engine compartment, including engine cooling modules, headlamps, fog lamps and wiring harnesses. The all-in-one assembly concept is becoming more popular with automakers.

One of the best examples of the modular production method is used to build the Jeep Cherokee and the Jeep Wrangler. The popular vehicles use front-end modules and fascia systems produced on a just-in-time basis by Magna T.E.A. M. Systems Inc., a division of Magna International Inc.

Magna, the world’s second-largest Tier One supplier, provides automakers with a wide variety of subassemblies, including closures, electronics, exteriors, mirrors, power trains and seating. It also offers contract manufacturing services in Europe.

Magna T.E.A.M. (Toledo Engineered Automotive Modular) Systems operates flexible assembly lines that supply FCA’s Toledo, OH, factory that builds the Cherokee and the Wrangler. In addition, a “sister” plant in Brownstown, MI, services Ford’s Flat Rock Assembly Plant and GM’s Detroit-Hamtramck Assembly Plant.

“Our assembly processes are flexible so that we can better support our customer requirements,” says Josh Gasaway, general manager. “We have an enthusiastic continuous improvement culture which gets all employees involved. Through innovation, employee focus, leadership and great employees, our facilities are becoming a benchmark in the industry.”

“We try to keep both plants standardized,” says Gasaway. “Department managers in Toledo also have the same ownership areas at the Brownstown plant, which is only 45 minutes away.”

Big Demand

The Jeep brand is celebrating its 75th anniversary this year. And, its lineup of sport utility vehicles (SUVs) is more popular than ever. Thanks to low gas prices and pent-up consumer demand, the SUV segment is booming.

Jeep recorded sales of more than 1.2 million units worldwide in 2015—the highest total in its history—setting a global sales record for the fourth consecutive year. Sales of 1,237,583 vehicles improved upon 2014 levels by 22 percent.

FCA is pinning its future on the profitable Jeep brand. In fact, the company plans to stop building small and midsize sedans to free up production capacity to make more SUVs and pickup trucks.

Over the next three years, FCA intends to double the number of Jeeps sold worldwide, pushing production beyond 2 million units. It hopes to accomplish that goal by offering new editions of the Wrangler, such as a pickup truck version and vehicles equipped with diesel and hybrid power trains.

To keep up with booming demand, Jeep’s flagship factory in Toledo is running near peak capacity. That’s good news for Magna T.E.A.M. Systems, which is located a short drive away.

By combining lean manufacturing principles and state-of-the-art production tools and equipment, the 10-year-old facility builds front-end modules for the Jeep Cherokee and Wrangler, and front and rear fascias for the Cherokee. The parts are delivered in sequence just a few hours before they are installed on vehicles at FCA’s nearby assembly plant.

Magna touts its “designed for assembly and assembled to design” modular production concept as a way for automakers to streamline production, reduce floor space and improve quality.

Front-end modules (FEMs) are not something that most people think about when buying a new car or truck. It’s also not something that they see, because the FEM is covered by a fascia, which is a large molded plastic part that includes the bumper and the front grille.

FEMs are multipiece assemblies that integrate a number of components, such as air ducts, bumpers, engine cooling modules, headlamps, hood latches, horns and wiring harnesses.

The parts are typically inserted into a plastic injection-molded carrier that’s attached to a ready-to-install structural frame made out of lightweight hydroformed components and stamped metal brackets, which is equipped with self-locating fasteners. FEMs and fascias are assembled and shipped in sequence to a customer’s assembly plant.

Traditionally, FEMs used structural carriers comprised of multiple stamped steel assemblies that were welded together. Headlamps and other individual components were attached on trim lines at an automaker’s final assembly plant.

Thermoplastics now allow engineers to mold in features and locators. They can also integrate a number of previously separate subsystems and functions into a single component that saves money, reduces weight and provides for faster, more accurate and less costly assembly.

Modular subassemblies also help improve fit and finish on the front end of a vehicle by locating bumpers, headlamps, hood latches and other components to the vehicle’s datum scheme. In addition, FEMs can be added late in the build sequence, which improves ergonomics and allows operators on OEM final assembly lines easier access to engine compartments.

Lean Thinking

Lean manufacturing principles form the backbone of Magna T.EA.M. Systems’ operation. The Brownstown and Toledo plants use a world-class lean manufacturing system. It consists of more than 25 measurables and key performance indicators that support pillars, such as customer service, employee satisfaction, manufacturing excellence, quality and supply chain. Each of the pillars is “owned” by a cross-functional team at each plant.

“Our drive for continuous improvement reflects on everything that we do here,” says Gasaway. “We do that by having everyone on the plant floor and in the office fully engaged by constantly teaching and preaching lean concepts. We encourage each team member to try and eliminate waste out of their daily jobs.

“Good training and development is essential to our success,” adds Gasaway. Before new employees are hired, they must participate in an extensive two-day testing process. Candidates are exposed to basic assembly tasks and put through a variety of aptitude and skill tests.

A key tool in Magna T.E.A.M. Systems’ lean manufacturing effort is a series of P.R.I.D.E. (Platform for Resolving Issues and Driving Excellence) boards located in all corners of the plant. “They show both lead and lag measurables, along with corresponding open issues,” says Gasaway. “Every team has a board in their area and they use it for daily stand-up meetings, walk-about reviews and problem-solving sessions.”

Another continuous improvement tool in the plant is an incentive program called Lean Thinker, which consists of a small slip of paper that employees can fill out and turn in.

“This is our employee suggestion program,” explains Gasaway. “All team members are encouraged to fill out these forms that support the removal of the seven types of waste, or identify a safety or ergonomic concern. Each form is reviewed and sorted according to its feasibility and potential cost saving. All employees receive feedback on each submission.”

Flexible Assembly Lines

Magna T.E.A.M. Systems operates six high-mix, high-volume assembly lines at its Brownstown and Toledo plants. The typical front-end module comprises up to 50 components, depending on the vehicle make, model and optional features.

As consumers demand vehicles with more features, the manufacturing process is becoming more complex. In fact, there are 15,000 assembly variations on the Cherokee front-end module alone.

The fascia is not as complex as a FEM, but it also has many different part options, including different safety sensors, structural brackets, surface colors and wiring harnesses.

“Managing the part variation—from inventory to how we present it to the operator to error proofing— is the biggest challenge that we face on a daily basis,” says Gasaway. “Every time new features and options are introduced by our OEM customers, it presents more of a challenge.”

The 177,000-square-foot Toledo plant produces more than 1,000 FEMs a day for the Jeep Cherokee and and more than 800 for the Wrangler.

“There are also more variations, ranging from headlamps to wiring harnesses,” says Gasaway. “For instance, there are different bumper beams, headlamps and wiring harnesses.”

Parts kitting ensures that assemblers get the right part at the right time at the right workstation. Employees scan components when selecting parts, which are put into reusable totes that are delivered just in time to the assembly lines.

“This eliminates wasted motion and allows operators to concentrate on the value-add assembly process,” says Gasaway. “Another big benefit of parts kitting is the ability to clearly see the shop floor. It’s hard to line balance when there’s a hundred racks of parts sitting around a workstation and you can’t see the process.”

Magna T.E.A.M. Systems uses flexible workstations and workcells that can be changed in less than an hour, if necessary.

“The biggest challenge of flexible, just-in-time manufacturing is identifying the correct equipment to use to minimize downtime,” claims Gasaway. “We can’t afford to be down for 30 minutes, because that would shut down our customer’s assembly line. Back-up systems, such as emergency generators, and good contingency plans are essential.

“There has to be a sense of urgency on the part of everyone on the plant floor, including management,” notes Gasaway. “A solid IT structure and a qualified technical group is a must in order to react quickly and break down barriers if there’s a problem on the assembly line.”

New Technology

Balancing lean manufacturing and state-of-the-art production technology is critical to Magna T.E.A.M. Systems’ success. “They both go hand in hand,” says Gasaway. “But, lean manufacturing typically drives technology. You must have a continuous pursuit to be innovative on the plant floor.”

Four years ago, the Toledo plant invested in an automated guided cart (AGC) system on the Jeep Cherokee front-end module and front fascia assembly lines. AGCs are smaller, cheaper and easier to install than traditional automated guided vehicles. The AGCs also allowed Magna more flexibility over conventional conveyor systems.

They are designed for applications where lighter loads and flexibility are required. The carts are guided by floor-mounted magnetic tape that can be easily reconfigured on an assembly line.

Magna T.E.A.M. Systems uses more than 30 AGCs in the Toledo plant. Two-thirds of them are used on the assembly line that builds front-end modules for the Jeep Cherokee. The remainder of the carts are used on the line that assembles front fascias for the Cherokee.

Each cart holds a fixture and a kitted parts bin. One of the AGC lines is laid out in a straight-line configuration, while the other one is S-shaped.

“The carts give us the ability to create different line shapes, because we’re limited on space,” says Gasaway. “Those changes would be very difficult and expensive to do with a traditional in-line or power-and-free conveyor.”

The plant also uses an eight-position carousel conveyor to build FEMs for the Jeep Wrangler, which uses less complex assemblies than the Cherokee.

Unlike traditional assembly lines, operators perform all production tasks. They face inward as the floor revolves slowly in a counter-clockwise direction. Fastening tools are suspended from the ceiling, while part bins remain stationary and surround the carousel, which makes a complete revolution every 8 minutes.

“The carousel system allows us to flex our labor and not have to change standardized work,” says Gasaway. “When necessary, we can build at a slower rate and minimize our cost impact.”

To improve productivity and reduce defects, operators throughout the plant use DC electric fastening tools. That allows Magna to achieve impressive delivery and quality statistics, without sacrificing safety.

A wide variety of angle, straight and pistol-grip tools are used on the assembly lines. The plant also uses some battery-powered tools that are Bluetooth-equipped and interact with a manufacturing execution system (MES).

All tools are tied into networked controllers so that run-down information can be accessed, torque values can be analyzed, and predictive maintenance can be performed by engineers.

“We keep a ‘birth certificate’ for each product that we build,” says Gasaway. “The multipage history report contains a variety of information. In addition to torque values, it tells us things such as who built the item, when it was built, how long it sat in the workstation and what parts were added to it.”

Error Proofing

Magna T.E.A.M. Systems makes widespread use of bar coding technology to eliminate human error and production mistakes. Operators scan bar codes wrapped around their wrists to ensure that they’re assembling the correct product on the high-mix production line.

“All operators use bar codes to log into their workstation so that we have a record of who’s building what part,” says Gasaway. Electronic work instructions displayed at every workstation address error proofing and serve as a visual aid to operators.

“The paperless system is a way for team members to interact while building a part,” explains Gasaway. “Because of all the nuances involved in high-mix assembly, assemblers must constantly look at the screen to ensure that they’re using the correct component while correctly building to standardized work and validating torque values.”

In 2009, Magna T.E.A.M. Systems became vertically integrated when it added a plastic injection-molding operation. The Toledo plant currently operates 10 machines on three shifts so that it can produce 90 percent of the plastic parts it needs in-house.

Robots are used in the molding department for post-production applications, such as deburring and deflashing. The plant also uses robots for rivet insertion, adhesive bonding and ultrasonic welding applications.

Magna T.E.A.M. Systems prides itself on timely delivery and sequenced delivery, which helps reduce parts inventory, reduces waste and increases efficiency.

The Brownstown and Toledo plants ship sets of front-end modules and fascias based on a live broadcast received from OEM assembly plants. The parts arrive on semitrailers, are unloaded and delivered directly to the line, where they are attached to vehicles.

“We receive the broadcast information from the OEM after the body shop paints a car,” says Gasaway. “It’s usually a three- to five-hour window.”

Process control operation and monitoring in the Magna plant is handled by the MES system. “It drives standardized work throughout our workcells,” explains Gasaway.

The entire sequencing process is automated, including everything from receiving the build-order broadcast to shipping the bill of lading. In addition, electric fastening tools, bar code scanners and RFID tags are tied into the system for error proofing.

Fully assembled FEMs and fascias are delivered to a quality inspection station where electrical systems are tested for continuity and functionality. In the Toledo plant, subassemblies that pass are automatically transported to the shipping dock via a pallet conveyor system. An error-proofing station built in-house uses seven cameras to confirm that parts are assembled and sequenced correctly.

All shipping racks have RFID tags on them that interact with the outbound shipping sequence control system. A reader ensures that racks are inserted into a semitrailer in the right order. Each semitrailer holds more than 40 pallets, which are automatically loaded using six-axis robots.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!