Cloud-Based CAD Software Aids Wire Harness Design

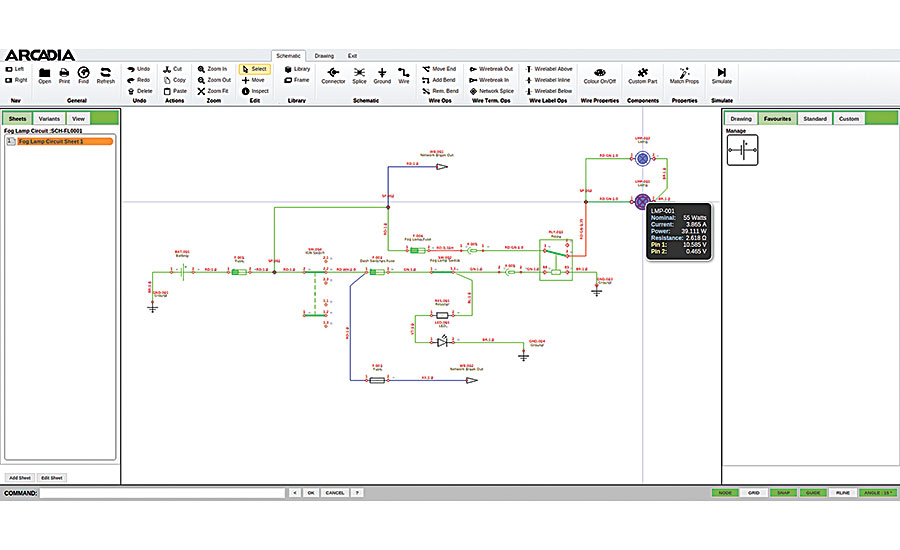

Arcadia Schematic lets engineers interactively place and connect electrical components to create schematic drawings, enabling real-time simulation and analysis. Engineers can draw, evaluate and test large full-vehicle schematics spread over more than 100 sheets. Illustration courtesy Cadonix

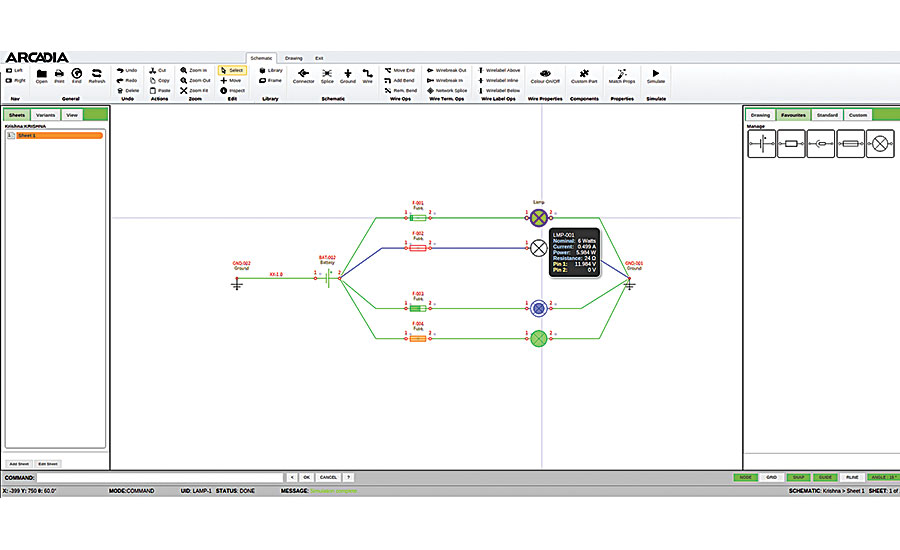

With Arcadia Schematic, engineers can evaluate wire sizing, voltage drops, fuse-blow currents and times, signal flow, short circuits, and cross-page connectivity. Illustration courtesy Cadonix

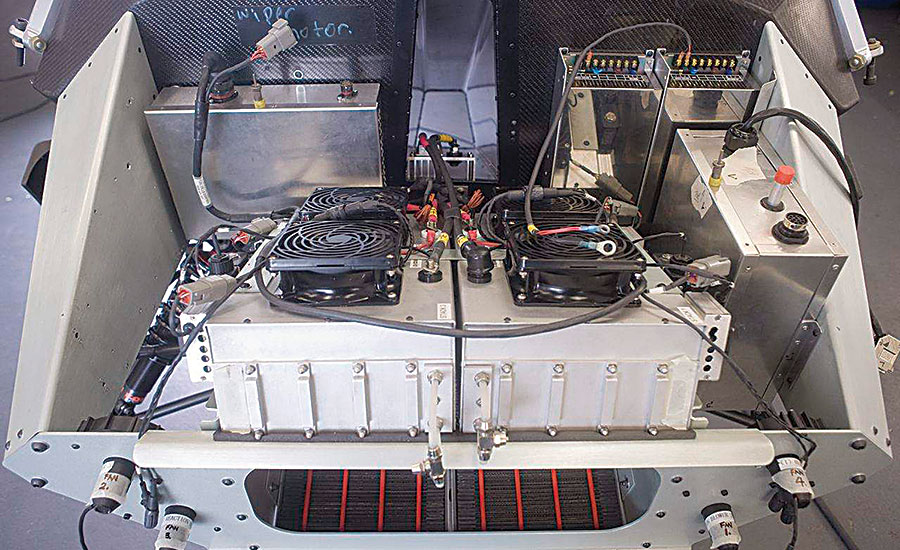

U.K. start-up Riversimple will soon introduce a new, environmentally friendly vehicle powered by fuel cells. Arcadia CAD software was instrumental for designing the vehicle’s electrical system. Photos courtesy Riversimple

U.K. start-up Riversimple will soon introduce a new, environmentally friendly vehicle powered by fuel cells. Arcadia CAD software was instrumental for designing the vehicle’s electrical system. Photos courtesy Riversimple

MasterMover’s ability to customize tugs to suit individual customers gives it an edge on the competition. Arcadia CAD software allows engineers to quickly modify wiring harnesses to accommodate design changes. Photo courtesy MasterMover

In the automotive industry, design, test and manufacturing functions can be geographically remote from each other and are often outsourced. The traditional model of CAD, in which companies buy ‘seats’ of a design tool that are assigned to specific workstations, isn’t aligned with this reality. Photo courtesy Garddian UK Ltd.

With Arcadia software, harness protection elements, such convoluted tube and heat shrink materials, can be rendered in different levels of detail. Photo courtesy Pacific Insight Electronics Corp.

Early next year, U.K. automotive start-up Riversimple will introduce a radically new, environmentally friendly vehicle. With a body made of lightweight composites, the two-seat electric vehicle will be powered by hydrogen fuel cells. The company is aiming for fuel efficiency of more than 200 mpg, a range of 300 miles, acceleration from 0 to 30 mph in 5.5 seconds, and a cruising speed of 55 mph.

“It emits nothing but a tiny amount of water,” says David Rothera, vehicle electronic engineer at Riversimple.

The vehicle will be driven by four electric motors, one in each wheel. When the car is braking, the motors generate electricity, a concept known as regenerative braking. Super-capacitors store this energy to provide 80 percent of the power for acceleration. Power for cruising comes from the fuel cells.

Decoupling the power for acceleration and cruising means that the fuel cells need only be sized to meet the maximum steady demand when cruising. This is usually only about 20 percent of the maximum power required when accelerating. In a conventional car, the engine provides the power for both acceleration and cruising. Since a car is only accelerating for 5 percent of the time, and the power needed for acceleration is five times what it is needed for cruising, that means that for 95 percent of the time, the car is carrying around a power train five times larger than necessary.

The vehicle’s design isn’t the only thing that’s innovative. Riversimple also wants to operate differently, believing in broad corporate ownership, open source development and design, leasing instead of selling the cars, and distributing manufacturing among many small companies. R&D is done at the company’s U.K. headquarters by an engineering team drawn from automotive, aerospace and motor racing firms; design is led by Chris Reitz, former design chief for the Fiat 500, at a studio in Barcelona, Spain.

Given the distributed nature of the organization and the complexity of the vehicle’s electrical system, Riversimple uses Arcadia wire harness design software from Cadonix Ltd. in Long Crendon, U.K., to ensure everyone is on the same page. Because Arcadia is cloud-based, engineers can access the software and design files from anywhere.

“Cloud-based design is new for us,” says Rothera, “but even at this early stage we’ve come to appreciate the flexibility of being able to access the design from anywhere. Arcadia is a flexible and intuitive tool, which will be fully able to address the need [for an electrical] return path and other issues specific to the design of this unusual vehicle.”

Suite Software

Arcadia is a cloud-based suite of CAD programs for electrical wiring design, analysis and report documentation.

The suite consists of two programs: Arcadia Harness and Arcadia Schematic. Arcadia Harness can be used as a stand-alone wire harness design and layout tool, or it can be used in conjunction with Arcadia Schematic.

Arcadia Harness includes a 2D drafting package, enabling the creation of a harness bundle layout. Connectivity data can be entered manually, imported from a structured wire list, or transferred directly from Arcadia Schematic. In the latter case, wire data will populate the harness bundles automatically.

Connector tables can be placed at the end of the bundle runs, and these tables are automatically annotated from the data brought in from Arcadia Schematic or a structured list. Graphical representations of the connectors can be shown either from a wire entry view, a face view, or isometric views.

Terminals, seals and plugs are selected automatically based on the wire and cavity size. Bundle diameters are automatically calculated based on the number and size of wires in each bundle segment. Splices can be positioned according to rules, and splice loadings can be optimized based on entry from the left or right side.

Wires can be moved from one cavity to another by simply picking up the end and relocating it. Any changes made during the layout of the harness are automatically back-annotated to the schematic.

Harnesses can be drawn 1-to-1 or not to scale (NTS). Various bundle finishes, such as tape or heat-shrink tubing, can be rendered in different levels of detail.

Mechanical components, including clips, grommets and brackets, can also be pictured. NTS drawings can be automatically converted to 1-to-1 at the touch of a button to create a full-scale form board. Harness segments and branches can be manipulated to fit into a form board of a specific size with branches being folded into position manually.

Arcadia Schematic lets engineers interactively place and connect electrical components to create schematic drawings that can then be used for real-time simulation and analysis. Engineers select components from a comprehensive library of intelligent symbols. The database includes wires, motors, lamps, in-line connectors, splices, terminals, switches, relays, fuses, diodes, LEDs, resistors, batteries, electronic control units and ground points.

The software provides interactive feedback on the entire circuit through tool tips, and animated views provide instant feedback on electrical behavior. Engineers can draw, evaluate and test large, full-vehicle schematics spread across more than 100 sheets.

Real-time animated simulation paints a clear virtual picture of the electrical system and how it will behave under deployment. Engineers can confirm circuit loading, component function and error conditions through an animated graphical interface. The simulation can provide information on wire sizing, voltage drops, signal flow, short circuits, and the currents and times needed to blow fuses.

The benefit of simulation is that engineers can work on the electrical design simultaneously with the mechanical design. Physical prototypes are not necessary.

Arcadia can automatically generate a range of reports, including bills of material, connectivity lists, wire usage, and analysis reports. The software supports a variety of output formats, including IsoView-compatible SVG, linked PDF reports, and XML data. Using the document publishing tool, engineers can create custom PDF versions of the schematics ready to print, plot or publish. The PDFs are text-searchable, so it’s easy to find a particular component or signal of interest.

User Experience

AQ Wiring Systems is a global wire harness manufacturer with assembly plants in Poland, China, Lithuania, Mexico and India. With 1,300 employees worldwide and annual turnover $73.5 million, the company counts ABB, Bombardier, Deutz, Linde and Volvo among its customers. Its manufacturing systems are standardized to ensure that customers receive the same high-quality and delivery performance everywhere. With common technology and processes, transfer of production between plants can be executed smoothly.

AQ recently purchased Arcadia for use at its site in Lodz, Poland.

“We need…design flows that are fast, flexible and adaptable,” says Mikael Alvarsson, managing director of AQ Wiring Systems Poland. “From the first demonstration, we were impressed by Arcadia, and see it as an environment that raises the bar in automotive wiring harness design.

“Cadonix has been able to create an environment that is significantly more flexible and intuitive, while retaining a lot of similarities to simplify the learning process for our design team. The ability to import databases and designs seamlessly from our existing design environment further speeds the adoption process. The interfaces to other systems are a particular strong point of Arcadia, helping us integrate the new tool smoothly into both our existing flows and our customer’s systems.”

Jankel, a manufacturer of armored vehicles, also uses Arcadia. The company has assembly plants in the U.K., U.S. and Jordan. Its products range from lightweight military vehicles to blast-mitigating vehicle seats. Many of its products are based on production SUVs, like the Jeep J8 or the Toyota 200 Landcruiser, which it equips with armor and other protective gear. Although most of the company’s electrical design is associated with vehicles, Jankel expects that its seats will include more electric features in the future.

The company’s design challenges include converting stock vehicles to 24-volt operation and designing a complete and fully sealed military wiring harness. In other cases, engineers just need to provide extra protection to the existing harness or add wiring for accessories such as infrared lighting, “blues and twos,” and power management systems.

“Jankel requires a…CAD environment that fully supports our careful test and release procedures,” says Matt Smith, senior electrical engineer. “Arcadia stood out in terms of ease of use and flexibility, offering full electrical systems analysis, and supporting design for manufacture.

“A key requirement for us was interfacing the tool to our SAP purchasing environment and SolidWorks Enterprise Product Data Management, which we use to store and manage our engineering data. Cadonix worked with us to implement this functionality.”

“Each wiring harness design team [at Jankel] works in a different way, and we adapted Arcadia to suit each customer’s individual needs,” adds Jon Collins, sales director for Cadonix.

MasterMover, a manufacturer of electric tugs, was an early adopter of Arcadia. MasterMover purchased Arcadia for use at its assembly plant in Derbyshire, U.K.

“MasterMover electric tugs are becoming increasingly sophisticated. We are introducing CANbus to support the introduction of new features, such as wireless control and more advanced steering systems,” says Dan Evans, electrical design engineer at MasterMover. “We need to bring more complex wiring harnesses to market more quickly, and Arcadia is exactly the design environment that we need to achieve this.

“MasterMover’s ability to customize tugs to suit individual customers is an important differentiator,” he continues. “The Arcadia environment makes it quick and easy to adapt the wiring harness to accommodate design changes. The real time simulation feature allows us to see very quickly what impact changes will have before a prototype is built. …The cloud based model allows us to work live from customer sites if we need to.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!