Collaborative Robots Enter the Mainstream

After decades of hiding behind safety barriers and protective cages, robots are starting to work alongside humans on assembly lines. Photo courtesy Audi AG

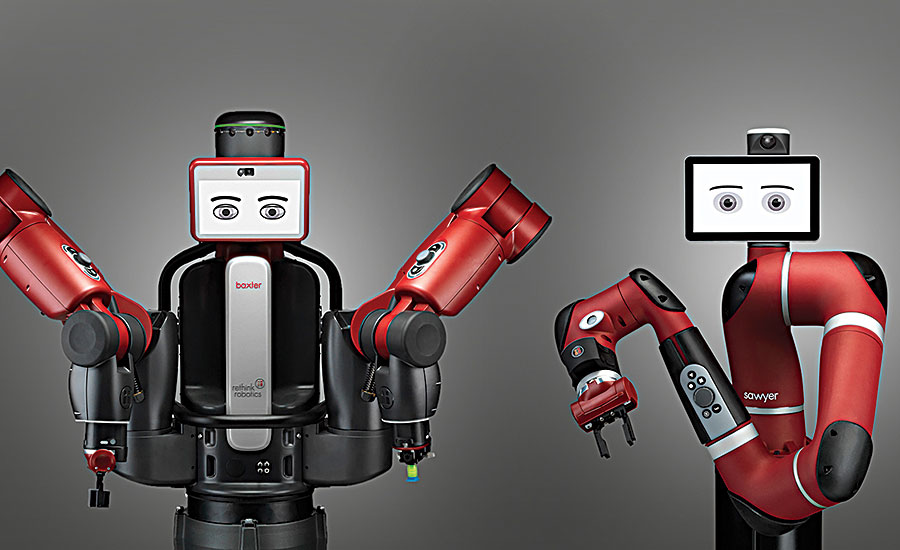

Next-generation machines equipped with state-of-the-art sensor technology allow robots to operate side-by-side with humans. Photo courtesy Rethink Robotics Inc.

This robot was designed to meet the flexible and agile production needs of the consumer electronics industry and other assembly applications that require small parts. Photo courtesy ABB Robotics

Promises of safety, flexibility and increased productivity are luring engineers to consider the new generation of power- and force-limited machines. Photo courtesy KUKA Robotics Corp.

This collaborative robot helps manufacturers solve ergonomic challenges by handling applications that are physically demanding for humans, such as heavy lifting. Photo courtesy Fanuc America Corp

Collaborative technology promises to transform robots from dangerous machines to safe tools. Photo by Austin Weber

This SCARA robot relies on sensors that constantly limit collision forces and permit humans to safely access the robot’s active workspace while the machine is operating at full speed. Photo courtesy Precise Automation Inc.

Collaborative robots are the hottest segment of the robotics industry. Photo courtesy ABB Robotics

"Just like me, they long to be close to you.” That’s the refrain from a popular 1970s song by the late Karen Carpenter.

Those lyrics also apply to robots today. After decades of hiding behind safety barriers and protective cages, robots are ready to work alongside humans on assembly lines.

If they live up to all the hype, collaborative robots will transform manufacturing. However, the technology is clouded by several myths and misperceptions. There are also challenges and limitations, such as parts feeding and payload capacity. But, once those issues and concerns are resolved, human-robot interaction will become more common in factories.

Collaborative robots are the hottest segment of the robotics industry. Many engineers are intrigued by the potential of next-generation machines equipped with state-of-the-art sensor technology that allows robots to operate side-by-side with humans.

Technology pioneers Rethink Robotics and Universal Robots recently rolled out new models, while industry stalwarts like ABB and Fanuc have also entered the game and introduced collaborative robots of their own.

Rethink Robotics Inc. helped coin the term “collaborative” and spawned the new class of robots several years ago when it launched Baxter. Earlier this year, it unveiled a smaller machine called Sawyer.

“We have always considered a truly ‘collaborative’ robot to be one with power- and force-limited motion control, with internal sensors and inherent safety mechanisms that enable its safe operation among humans on production lines,” says Eric Foellmer, marketing manager at Rethink Robotics. “Hand-guided programming is another important element of the category.

“The net effect of that is a robot that can work safely next to people in production environments without safety guarding; can be trained by hand to do a task; and is inherently designed to modify its behavior to work around humans,” explains Foellmer.

“Unlike traditional industrial robots, collaborative robots are lightweight, flexible and can easily be moved and reprogrammed to solve new tasks,” notes Scott Mabie, general manager for Universal Robots’ Americas division. “[They meet] the short-run production challenge faced by companies adjusting to ever more advanced processing in smaller batch sizes.”

“With traditional robots, the capital costs for the [machines] themselves account for only 25 percent to 30 percent of the total system costs,” claims Mabie. “The remaining costs are associated with robot programming, setup and dedicated, shielded workcells. The ‘out of box experience’ with a collaborative robot is typically less than an hour. That’s the time it takes to unpack the robot, mount it and program the first simple task.”

“Safety barriers are expensive, consume a great deal of bench and floor space, obstruct access to equipment and reduce productivity,” adds Brian Carlisle, president and CEO of Precise Automation Inc., which recently unveiled a line of robots for benchtop assembly applications, such as adhesive dispensing and screwdriving. The company’s PP100 Cartesian robot relies on sensors that constantly limit collision forces and permit humans to safely access the robot’s active workspace while the machine is operating at full speed.

Carlisle, a robotics industry veteran, believes that collaborative machines are not a fad. “It is [now possible to deploy] inherently safe robots with limited force and inertia that cannot hurt people,” he explains. “These robots can be less expensive than heavier payload machines. Low-cost, safe robots open up new application areas and reduce assembly costs below offshore costs.

“These robots are now cheaper than the cost of labor in China,” claims Carlisle. “That’s driving a lot of new interest in automation.”

According to Carlisle, collaborative robots are ideal for small-part assembly applications common in the consumer electronics and medical device industry. In particular, he says there’s a big need for automated driving of M1 screws.

“Collaboration” Defined

The term “collaborative robot” is defined broadly. Every supplier has a different spin on the topic.

Generically, it refers to “systems capable of independent movement that share a workspace simultaneously with humans; that work interactively with them; and that assume there will be some mutual physical contact,” explains Dan Kara, robotics practice director at ABI Research Inc.

However, Kara says it’s important to separate the hype from reality. “The biggest myth is that collaborative robots are inherently safe,” he warns. “In the broad definition, they’re not as safe as advertised and require some safety measures. Also, some degree of programming and systems integration is required.”

Kara claims that the technology is characterized by four capabilities:

- Sharing a workspace—robot and human share a common workspace simultaneously.

- Interactive collaboration—robot and human work together interactively.

- Independent movement—robot and human move independently of each other.

- Physical contact assumed—there is some physical contact between a robot and a human, either directly or through an intermediary object.

According to Jeremy Marvel, Ph.D., a computer scientist at the National Institute of Standards and Technology (NIST), there are several levels of collaboration. “The current state of the art is sequentialcollaboration, which involves robots and humans working together discretely to complete various steps in a production process,” explains Marvel, who is involved in a multiyear project studying the performance of collaborative robot systems, including assembly applications.

“The new types of robots emerging today are capable of simultaneous collaboration, in which two or more parties are performing separate tasks on a shared workpiece at the same time,” says Marvel. “The next step will be supportive collaboration, in which two robots or a robot and a human are working simultaneously on the same task on the same product. That future-forward scenario is still at least five years down the road.”

On the outside, today’s state-of-the-art machines look similar to traditional Cartesian, SCARA and six-axis robots, but they’re actually much different. They are typically lighter and slower, and they have smaller payload capacities. Their mass and momentum are effectively reduced.

“Collaborative robots offer many advantages over traditional industrial robots for certain applications,” claims Foellmer. “They’re safe to operate next to people without cages, so they can be utilized in highly manual production lines that have historically been off-limits to traditional robotic systems.

“Most robots in the category are also significantly easier to program than their industrial counterparts,” says Foellmer. “With our robots, line workers and other nonengineers can easily train the robot to do a meaningful task.

“[Collaborative robots] are also extremely flexible, meaning they can be repurposed quickly and easily to work on different tasks in a facility,” adds Foellmer. “And, because they require less physical infrastructure to operate, they can fit more readily into workspaces designed for humans. This helps to maximize their return on investment, since you’re able to utilize them across multiple lines in a plant.”

“Collaborative technology promises to transform robots from dangerous machines to safe tools,” claims Enrico Iversen, CEO of Universal Robots, which recently unveiled its third robot, the UR3, a tabletop machine that’s designed for assembly applications, such as adhesive bonding and screwdriving. “Traditional training is not required to program and use them.”

Growing Demand

Collaborative robots are not just a passing fad. As the technology matures, they will become a key segment of the manufacturing automation market.

More than one-quarter (27 percent) of respondents in ASSEMBLY’s 2015 State of the Profession study expect to deploy collaborative robotic technology during the next 12 months. Not surprisingly, more than one-third (34 percent) of assemblers that plan to invest in next-generation robots claim that it’s because they are having trouble finding skilled workers. The next biggest reason is to improve productivity.

Almost one-half (44 percent) of manufacturers in the transportation equipment sector, which includes automakers and suppliers, plan to invest in collaborative robots. Other industries eager to allow humans and robots to work in close proximity on assembly lines include computer and electronic products (39 percent) and contract manufacturers (32 percent).

According to a recent study conducted by ABI Research, the collaborative robotics sector will increase tenfold between 2015 and 2020, reaching more than $1 billion.

“That growth will be fueled by three key markets: electronics manufacturers and electronics manufacturing services companies; small- to medium-sized manufacturers; and manufacturers seeking robotic solutions optimized to support agile production methodologies,” says Kara.

“This new class of robots was developed in response to a number of pressing social drivers and business imperatives, and aided by ongoing technological innovation and dropping prices for powerful enabling technology,” explains Kara. “The sector is very dynamic and is expanding rapidly, with new product offerings being released into the market from both established companies and smaller, emerging firms.”

Promises of safety, flexibility and increased productivity are luring engineers to consider the new generation of power- and force-limited machines.

“We are on the cusp of the next level of robotic applications,” proclaims Claude Dinsmoor, general manager of material handling robotsat Fanuc America Corp., which recently unveiled the CR-35iA collaborative robot, which boasts a 35-kilogram payload capacity. The machine is currently in use at General Motors for heavy-lifting applications, such as inserting spare tires into vehicles moving down the assembly line.

“In this new [era], we can unlock more productivity by opening up workspaces and eliminating some hard guarding,” explains Dinsmoor. “This was not possible until the latest robot safety standards were released in the last few years.”

“The ability to deploy a collaborative robot in close proximity to a person without having to install safety guarding or reconfiguring the workspace is a big advantage for companies with limited space and budgets,” adds Rethink Robotics’ Foellmer. “Another reason for so much interest today is the ability for these robots to be deployed in environments where conventional automation cannot be, [due to] concerns over safety, high cost, programming complexity or lack of flexibility.

“The ability to deploy a safe, affordable, easily programmed, flexible automation solution represents an unprecedented opportunity for manufacturers to automate repetitive tasks that could only be done with human labor previously,” Foellmer points out.

Manufacturers of products such as cameras, laptop computers, smartphones, toys and watches have been early adopters of collaborative robots.

“Few production arenas are changing as quickly as small-parts assembly,” notes Phil Crowther, global product manager for small robots at ABB Robotics. “The electronics industry, in particular, has seen demand for products skyrocket past the supply of skilled labor. As conventional assembly methods diminish in value, manufacturers are finding it strategically and economically imperative to invest in new solutions.

“Small parts assembly is a huge market for collaborative robots,” claims Crowther. “This is an emerging market that’s still just in its infancy stage.”

Earlier this year, ABB unveiled a dual-arm collaborative robot called YUMI. It features a magnesium skeleton covered with a floating plastic casing wrapped in soft padding to absorb impacts.

“While YuMi was specifically designed to meet the flexible and agile production needs of the consumer

electronics industry, it has equal application in any small parts assembly environment,” says Crowther. Features include dual arms, flexible hands, a universal parts-feeding system, camera-based part location, lead-through programming and a state-of-the-art motion control system.

“The main interest in collaborative technology today is driven by the ability for these new robots to complete tasks that were difficult or impossible for standard articulated robots to complete before,” says Mike Beaupre, director of new market sales at KUKA Robotics Corp., which offers a collaborative, seven-axis robot called the LBR iiwa (intelligent industrial work assistant). “The highest demand is coming from the consumer electronics industry, especially for [assembling smartphones, tablet computers and other products that use small components].

“Collaborative robots are more accepted and used by European manufactures, mainly due to the application of standards already published and in effect, such as ISO 10218, and opinion papers such as that from VDMA in Germany,” adds Beaupre. “But, ease of use and portability is [generating] much attention from small- and medium-sized companies that need more flexible automation solutions, due to lower production volumes and shorter lot runs.”

“We’ve experienced significant demand across many different industries,” claims Rethink Robotics’ Foellmer. “Typical applications include pick-and-place, line loading, material handling and machine tending. If you walk around a plant and see lightweight parts being moved around repetitively and in close proximity to people, you’ve likely found a great job for [collaborative] robots.”

Assembly Applications

Manufacturers that have already adopted collaborative robots include automakers such as BMW, GM and Volkswagen. The machines are also in use on assembly lines at STIHL Inc. (the recipient of ASSEMBLY’s 2014 Assembly Plant of the Year award).

One manufacturer that has benefitted from closer human-robot interaction on its assembly lines is Audi AG. Engineers recently deployed collaborative robots as part of the PART4you initiative at Audi’s main factory in Ingolstadt, Germany, which produces the A4 sedan, the A5 coupe and the Q5 sport utility vehicle.

“The new, direct cooperation between humans and robots is an enormous help,” says Johann Hegel, head of assembly technology development. “Until now, [assemblers] had to bend over material boxes to take out coolant expansion tanks.

“At first glance, this seems like a simple task, but with frequent repetitions, it can lead to back problems,” explains Hegel. That task is now handled by a robot that works hand-in-hand with [humans] and is fitted with a camera and an integrated suction cup. This enables it to pick up the components from the boxes and pass them to assemblers without any safety barrier, at the right time and in an ergonomically optimal position.

“In a production process with increasing diversity of model versions, PART4you provides [our] employees with important assistance,” claims Hegel. “It selects the correct component and holds it ready to be taken. This means that the employees no longer have to reach over long distances or bend down repeatedly. The robot becomes an assembly assistant operating at the same speed as the assembly

worker—not the other way around.”

Employees in the A4 body shop in Ingolstadt have been working with the same type of robot equipped with an adhesive nozzle instead of a suction cup. “In the body shop, the robots support the employees by applying adhesive to bonded seams,” says Hegel. “Instead of applying the adhesive to the body parts themselves, [assemblers] only have to put them in place and start the automatic procedure.”

Another company that’s bullish on collaborative robots is Jabil Circuit Inc. The world’s third largest contract manufacturer is partnering with Rethink Robotics as an early adopter and field tester of Sawyer, a single-armed collaborative robot designed to assemble and test printed-circuit boards and other electronic components.

“Flexible automation that addresses shrinking product lifecycles and helps companies align with consumer trends is a critical technology initiative for manufacturers,” says John Dulchinos, vice president of digital manufacturing at Jabil.

According to Dulchinos, the former president and CEO of robotics pioneer Adept Technology Inc., the factory of the future will be predictive and collaborative. He believes collaborative robots will enable manufacturers to address speed and customization challenges in a high-mix production environment.

New Safety Standards

Before the collaborative robot market can really take off, manufacturers must continue addressing risk assessment issues and developing industrywide safety standards, such as ANSI R15.06:2012, ISO 10218:2011 and RIA TR R15.306:2014.

More guidance will be provided in TS 15066, which is expected to be published by the end of this year by the International Standards Organization. It will focus on power- and force-limiting robots, including the tools, fixtures, parts, end effectors and machinery within a robotic workcell.

“Until TS 15066 is published, manufacturers are using common sense and their own internal risk assessment standards to determine and mitigate risk levels provided by hazards in the robotic workcell,” says Rethink Robotics’ Foellmer.

“TS 15066 will greatly elaborate on the existing language and fill in a lot of the existing gaps,” adds Pat Davison, director of standards development at the Robotic Industries Association (RIA). “It will provide more than 40 pages of guidance.”

Next month, RIA will address the latest developments on the topic at the National Robot Safety Conference in Pittsburgh. And after the event, it’s hosting the International Collaborative Robots Workshop on Oct. 15.

The robotics industry is also in the process of developing standards for payload capacity and end-of-arm-tooling associated with collaborative machines.

“Starting in December, ISO will be embarking on a two-year project focusing on grippers and end effectors,” says Davison. “That’s important, because the gripper is the primary interface mechanism for human-robot interaction. If incidental contact occurs, that’s likely the place where it will occur. As a result, we’re starting to see some innovative end-of-arm tooling that looks radically different from traditional end effectors.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!