Lasers Remove Polymer Wire Insulation Quickly, Precisely

This polyimide wire was stripped using a CO2 laser. Photo courtesy Amada Miyachi Inc.

This laser ablation system includes high-speed galvanometers for beam steering and a custom feeding and rotating mechanism to accurately and repeatably position the wire. Photo courtesy Amada Miyachi Inc.

Femtosecond lasers produce extremely short pulses of light—10-15 second in duration. The pulses are so short that the material does not have time to conduct heat from the process area into the surrounding material. Photo courtesy Amada Miyachi Inc.

This table shows the lasers most commonly used for wire stripping, listed by suggested order of consideration, from top to bottom. There is a suitable laser for any combination of material, wire diameter and stripping requirements. Photo courtesy Amada Miyachi Inc.

Many medical device applications require stripping the outer layers of polymers from small diameter wire, and the laser is well suited for this task.

Laser stripping is a noncontact process that is very repeatable and easily automated. Lasers can selectively remove layers of insulation or areas of insulation. Compared with chemical-based stripping methods, laser stripping is safer, cleaner, less expensive and more sustainable.

Thin-diameter wire is used in various devices for cardiac rhythm management, neurological stimulation and radio frequency ablation. This wire is typically coated with an insulating polymer that must be removed in sections to expose the underlying metal conductor. The diameter of these wires is decreasing, making other stripping methods impractical. At the same time, stripping requirements are getting more complex. In some cases, insulation must be selectively removed from both ends of the wire, as well as sections in the middle.

The laser process imparts no physical force on the wire during the stripping process, so delicate wires with diameters as small as 50 microns can be stripped. The insulation is removed with a focused laser beam (approximately 25 microns in diameter) directed by small mirror galvanometer systems. With the galvanometers, the position of the laser point is fully programmable in both the X and Y axes.

This enables highly tailored material removal, so parts or sections of insulation can be removed as needed. Changes to the size and location of the areas to be stripped can be made on the fly by calling up preprogrammed recipes.

The material is removed by one of two methods: ablation or cut and peel. The ablation method simply removes all the material from the wire as the polymer absorbs the light energy and is vaporized. The laser does not affect the wire beneath the insulation, because the power levels needed to remove the insulation are much lower than those that would damage the metal wire. This advantage can be augmented by selecting a laser wavelength that is readily absorbed by the polymer, but reflected by the wire.

The cut-and-peel method is not always possible. With this method, the laser makes a series of helical cuts in the insulation that mechanically free it from the wire. The insulation can then be removed by automated or manual means. This is typically done if the cycle time is critical and post-process material removal is acceptable.

Laser vs. Manual

Compared with manual processes for removing insulation, laser stripping offers numerous advantages.

The most common manual process involves dipping each wire into a solvent for a certain amount of time, and then scraping off any remaining material with a sharp knife. Quality and repeatability are hardly assured using this process.

Moving from a manual process to an automated one increases process control, ensures quality and increases throughput.

For example, one large medical device company recently transitioned from a manual process to a laser process for producing stainless steel guide wires used in intravascular interventional devices. About as thin as a human hair, the wire is coated with an organic material that makes it compatible for use in people. This organic coating must be stripped away from the microscopic metal core wire to enable connection to the guide wire’s distal end.

The laser process consistently and precisely strips the coating away from the wire. The laser is far less operator-dependent than the manual method. In addition, the laser takes only seconds to complete, whereas the previous process took approximately 8 minutes. Throughput rose by 250 percent, with an additional increase in yield.

The Right Laser for the Job

A number of different lasers can be used for wire stripping, depending upon the particular wire diameter, insulation material (polyimide, Pebax, polyethylene terephthalate, nylon and fluoropolymers), and feature requirements. There is a suitable laser for each combination of material, wire diameter and stripping requirements.

The sealed CO2 laser should always be considered first. With a wavelength of 10,604 nanometers, the CO2 laser is readily absorbed by every polymer, so it will work to a certain degree no matter what insulation material is used. Also, the CO2 laser is not readily absorbed by metals, so when all the insulation is removed and the laser hits the exposed wire, it has little effect for a relatively long time. This provides a large processing window and ensures the stripping process will be completed to established tolerances regardless of insulation thickness. In addition, the CO2 laser is the most cost-effective in terms of dollars per watt of power.

However, because the material is removed through thermal degradation, heat input can be an issue if the wire diameter is small. This may distort or even cut the wire, or the insulation can be overheated, causing discoloration and burr formation. (A burr develops when the material bulges or is raised. A burr can significantly increase the overall outer diameter of the wire.)

If a CO2 laser cannot be used for reasons of heat input control, the nanosecond laser should be considered next, specifically those at wavelengths of 355 or 532 nanometers. Nanosecond lasers produce light pulses of around 20 nanoseconds, removing insulation with much less heat than a CO2 laser. It can be used on smaller diameter wires, or where the removal edge must be well-defined with little or no burr.

The choice between 355- or 532---nanometer wavelengths is based on the insulation material. The 355-nanometer wavelength is better absorbed by more polymers. If the CO2 laser is likened to a large oxyacetylene blow torch, the nanosecond laser would be analogous to a smaller, more delicate torch that might be used for finishing off a crème brûlée. (The fiber laser operating at a wavelength of 1,070 nanometers, while popular for marking, welding and micromachining, is not well-absorbed by most wire insulation materials, and so is rarely used for stripping applications.)

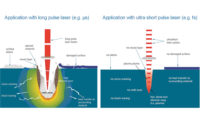

When extreme quality or minimal heat input is needed, the options to consider are the ultra-short pulse picosecond and femtosecond lasers. These two laser families produce pulse widths that are extremely short—picoseconds (10-12 second) and femtoseconds (10-15 second). The pulses are so short that the material does not have time to conduct any heat from the process area into the surrounding material.

This so-called “cold processing” enables the best quality results, but such a high quality level comes at a steep price. Ultra-short-pulse lasers cost about 25 times more than CO2 lasers and about five times more than 355- or 532-nanometer wavelength lasers. They may be appropriate for very high value products or for those with extremely thin wires (50 microns diameter), for which very fine control is needed.

Laser Stripping Systems

In medical device manufacturing, wires are not usually processed in reel to reel machines. Rather, they are processed with either a manually or automatically loaded machine that handles the wire pieces one at a time at the required length.

Essentially the wire stripper can either rotate the wire or use multiple heads to remove the insulation from the stationary wire. Sometimes the process, rather than the manufacturing environment, dictates which technique is used.

Amada Miyachi recently developed a laser ablation system that includes high-speed galvanometers for beam steering and a custom feeding and rotating mechanism to accurately and repeatably position the wire. Also included are features to manage heat balance in the part during ablation and facilitate clean removal of the insulation material.

A self-cleaning mechanism removes sticky debris from the ablation process area, which might contaminate tooling. The system takes a two-pronged approach to cleaning. A vacuum on the laser itself quickly removes smoke and airborne particulates. In addition, a high-tech brush mechanically cleans the tooling after every operation. This self-cleaning feature allows tens of thousands of wires to be run with minimal scheduled maintenance.

The key to success for any wire stripping application is development of the process itself. To make the right decision on which laser source and removal methodology works best, it is essential to test various options in an application laboratory with a range of lasers.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!