Insulation, Jacketing and Shielding

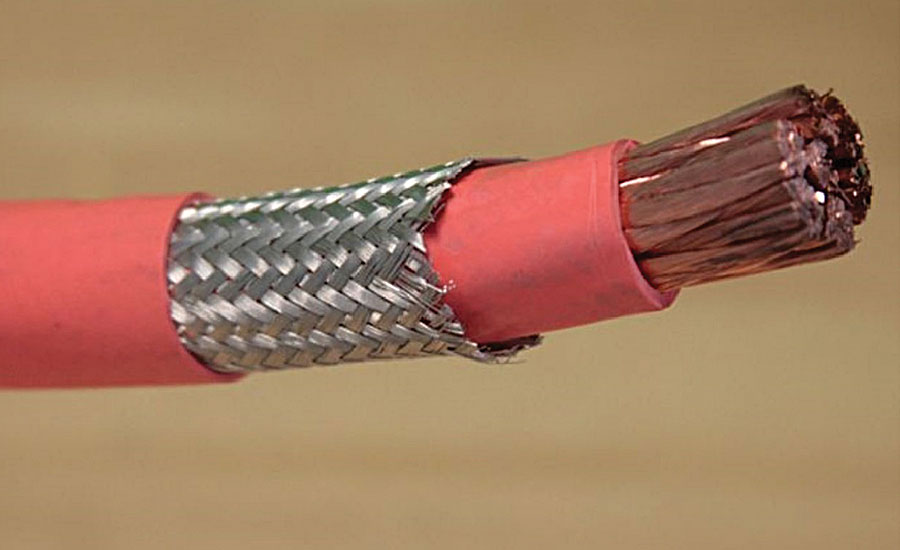

EXRAD 4/0 AWG cable measures nearly 1 inch in diameter and weighs 0.876 pound per foot. The 1,000-volt cable features a bright orange irradiated cross-linked elastomer (XLE) jacket, tinned copper braided shielding, and thin inner XLE insulation that surrounds 30 strands of bare copper wire. Photo courtesy Champlain Cable Corp.

The outer jacket of these various cables were slit with the JackStrip 8310 slitter. It handles 0.1- to 1-inch OD cable up to 19.7 inches long. Photo courtesy Schleuniger Inc.

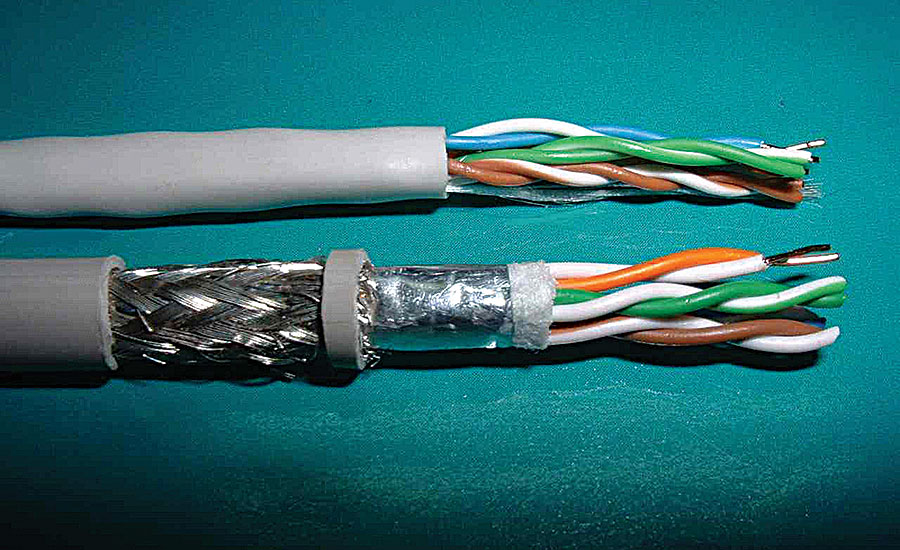

Twisted pairs is a type of spiral cable shielding. The two insulated conductors are uniformly twisted around each other the full length of the harness to minimize electromagnetic interference from other twisted pairs in the cable. Photo courtesy www.ecvv.com

Within every hybrid and electric-powered vehicle, there is a plethora of wire and cable. All of it is essential, but only a small portion stands out because of size, appearance or high-voltage capabilities.

The EXRAD 1,000-volt (UL 758 rated) battery cable is notable for all three reasons. Made by Champlain Cable Corp., the 4/0 AWG cable measures nearly 1 inch in diameter and weighs 0.876 pound per foot. Its irradiated cross-linked elastomer (XLE) jacket is only 0.08-inch thick yet strong enough to isolate any stray current. The jacket’s bright orange color means EXRAD meets EU standards for high-voltage cables.

Beneath the jacket is a tinned copper braid shielding. It provides 95 percent coverage of the cable’s thin inner XLE insulation (0.12-inch thick), which surrounds 30 strands of bare copper wire. More importantly, the shielding simultaneously prevents emission of electromagnetic pulse (EMP) waves and protects data and signal conductors from external electromagnetic interference (EMI).

Not every cable that harness manufacturers handle is as thick or complex as the EXRAD. But, every cable—and wire—requires the proper jacket, shielding and insulation if it is to achieve optimum performance.

Frequently, harness makers have no say in the final selection of these protective materials. In those situations, they focus on making sure the delivered product complies with the order form, and properly cutting, stripping or terminating the wire or cable.

Sometimes, however, a harness manufacturer is provided the OEM specs and required to pick a wire or cable supplier. By fully understanding the various materials used for insulating wire and jacketing and shielding cable, the manufacturer is better prepared to select the best wire or cable for any application.

Insulation and Jacketing

Because insulation and jackets are usually made of the same materials, the two terms are often used interchangeably. This is a mistake, as the words have distinct meanings.

“Insulation refers to the material in direct contact with the conductor, be it solid or stranded,” explains Rich Goyette, engineering and quality manager for EIS Wire & Cable. “Its purpose is electrical, that is, to keep the heat and electricity within the wire.

“The cable jacket, or outer sheath, is the thin material that covers insulated conductors. Its two purposes are mechanical: to hold the cable together, and to protect insulated wires from flame, oil, gas or water, depending on where the finished cable harness is installed.”

Back in the early part of the 20th century, wire and cable manufacturers insulated wire by wrapping it in cloth and lacquering the cloth to make it flame and heat resistant, notes Goyette. Soon after, other materials were used for insulation, including paper tape and oil-based materials.

With the development of fire safety standards for manufacturing after WWII, wires began to be insulated with either thermoplastic or thermoset materials. All insulation and jackets continue to be made of either of these two types of materials.

Thermoplastics can be melted and remolded repeatedly because they are composed of linear molecular chains that separate once heat is applied. The most common thermoplastic insulation materials include polyvinyl chloride (PVC), polyethylene (solid or foam), polypropylene, polyurethane, nylon, polyvinylidene difluoride (PVDF), fluorinated ethylene propylene (FEP), PTFE (Teflon), FEP Teflon, tetrafluoroethylene (TFE) andthermoplastic elastomer (TPE), which is processed like plastic but has the properties and performance of rubber.

Thermoset materials are molded once, and will burn if heat is continually applied. During the curing process, a thermoset’s polymer chains cross-link with other molecules to become a natural or synthetic rubber material. This is why a thermoset material sometimes has an XL (for cross-link) in its name, such as XLPE for cross-linked polyethylene. Other common thermoset materials are styrene-butadiene rubber (SBR) and silicone rubber.

“Where size and weight are not critical, PVC is the most popular insulation material because it’s cheap, bonds well, doesn’t fall apart and is easy to strip and terminate,” claims Scott Ziegler, product manager for Lapp Group USA. “Polypropylene and polyethylene are much stronger than PVC and don’t stretch very much. Polyurethane is very abrasive resistant, and Teflon offers excellent thermal stability and electrical properties.”

As for thermoset materials, rubber is frequently used in cable jackets and sometimes in wire insulation where the harness is exposed to intense heat for a long time. Neoprene (a synthetic rubber) is very soft and hard to cut.

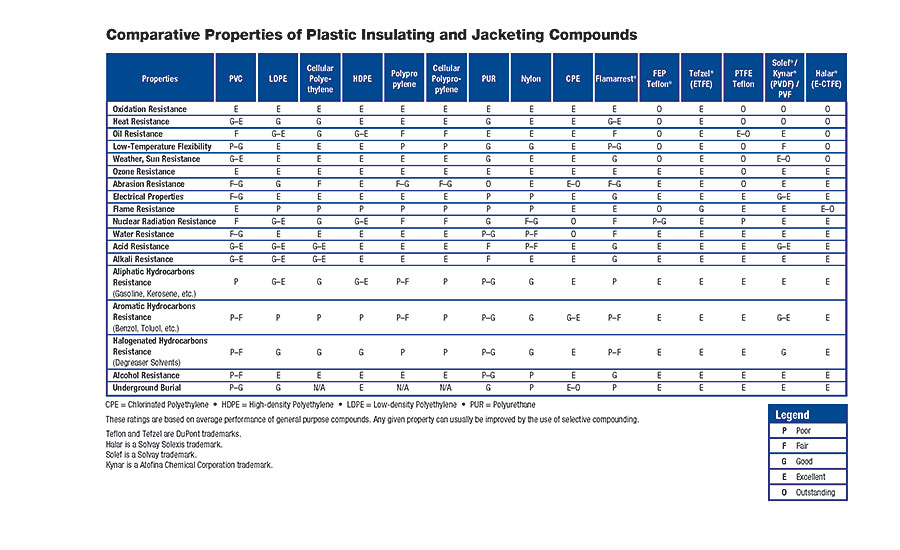

OEMs focus on two key factors when selecting insulation and jacketing material. The first is environmental conditions. If a cable or wire harness is subject to extreme heat, cold, dampness, chemicals or abrasion, it requires a rugged insulation material. Taken together, the most common thermoplastic and thermoset materials provide good to excellent abrasion resistance, and are effective within a temperature range from -67 to 392 F.

Another factor is the amount and speed of the current or voltage the wire or cable needs to carry. Not all materials are able to handle high currents for extended periods of time. For higher speed signals, foamed material (like polyethylene) is preferred. By injecting a chemical or gas into the material, a supplier creates air bubbles in the insulation. These bubbles enable the passage of high speed signals without being impeded.

Insulation and jacket thickness can range from 0.5 mil to several hundred mils, and is determined by the specified voltage. As a general rule, thicker wire carries a higher voltage and requires thicker insulation.

Insulation and jacketing come in many colors. The coloring process involves mixing a colorant with the resin compound during the primary extrusion stage. Colorant does not negatively impact cutting or stripping. However, because colorant is a contaminant, too much of it can cause weak spots and electrical failures in the insulation or jacket, says Goyette.

“Consistent insulation and jacketing are critical to the harness manufacturer’s ability to cut and strip wire and cable,” notes Linda White, product line manager for industrial cables at Belden Inc. “Changing suppliers frequently or using those known to change dimensions to cut costs without warning can create unanticipated havoc on an automated production line. It’s always easier to process a quality cable because its outer jacket has consistent dimensions and is round, not convoluted.”

Insulation adhesion to conductors can also cause stripping problems, says Frank Koditek, field applications engineer for industrial cables at Belden. This is especially true for rubber insulation.

To ease stripping, suppliers may place a very thin, clear-polyester separator tape between the insulation and conductor. Another option is to have a release agent applied to the conductor. The agent dries quickly, leaving a trace residue on the wire.

Shielding

The history of cable shielding stretches back to the early 20th

century and the need for telephone users to block out radio broadcasts being overheard on the telephone line. To eliminate this radio frequency interference (RFI), phone engineers tried wrapping the line with grounding wires. This worked for fixed installations, but when the line was subjected to flexing, the wrapped wires separated and interference returned.

Eventually, engineers began braiding tinsel wire, and then simple wire strands, over the conductors in the phone’s earpiece cords to reduce RFI. This process is known as served shielding.

Today, cable design engineers must still contend with RFI, as well as EMI and EMP. To block out these interferences and optimize cable performance, engineers rely on several types of shielding.

“Shielding has a different primary purpose for electronic cable than for power cable,” says Eric Wall, engineering manager for U.S. wire and cable at Anixter Inc. “In electronic cable, you’re typically trying to protect low-level signals at a wide range of frequencies, up into the gigahertz range. For power cable, you’re creating a ground plane for a single-frequency power sine wave (e.g., 60 hertz). The shielding equalizes the stress on the insulation and gives the fault current a path back to equipment, which can isolate the circuit if a fault occurs. This improves safety and also extends cable life.”

Served shielding is still used today and flexibility is its main appeal. The shielding is easy to unwind and terminate, but prone to be relatively inductive because it’s wrapped around the conductor. Typically, the shielding is crimped to a lug or termination post. It is often used in audio applications.

Another type of spiral shielding is twisted pairs, which was invented and patented by Alexander Graham Bell in 1881. The two insulated conductors are uniformly twisted around each other the full length of the harness to minimize interference from other twisted pairs in the cable.

Conductors can be solid or stranded. A solid conductor has less attenuation and spans longer distances, but a stranded conductor is very flexible for bending around corners.

Braided shielding is tight but flexible, according to Goyette. The braid shield is formed of groups of small-gauge wires on bobbins. These are laid side-by-side in the braiding machine, then woven over and under one another. Braided shielding usually covers 95 percent of insulated wire.

Strip braids are made of solid ribbons of conducting material to provide a more-uniform surface. This is an advantage at very high frequencies, and when combined with other types of shielding, forms a very effective EMI barrier.

Harness manufacturers often need to unbraid and cut the braided shield from shielded cable as part of the termination process. Pete Doyon, vice president of product management for Schleuniger Inc., says his company has developed a prototype machine (ShieldCut 8100) to quickly unbraid the braided shield and cut it to a preprogrammed length. Its targeted end-users include the military and aerospace manufacturers.

Currently available from Schleuniger is the JacketStrip 8310 slitter. This machine features rotating blades that axially and radially slit the outer jacket of out-of-round and multiconductor cables without damaging the shielding or inner conductors. It handles 0.1- to 1-inch OD cable up to 19.7 inches long. The semiautomatic slitting machine offers simple operation and short cycle times.

Foil shields consist of a very thin (0.0003 inch) metalized flexible plastic film that is spiral wrapped around the insulated wire. Because it is aluminum, the film needs to be crimped and is often combined with a noninsulated drain wire (current diverter) wrapped within a cable. The drain wire contacts the foil and is connected to ground at the harness source end to negate EMI.

To achieve 100 percent shielding effectiveness, a loose braid may be placed over the foil. This method works well as long as the cables are flexed only during installation and maintenance.

Twisted pairs also are available shielded (STP) with a metallic foil to further protect against excessive EMI. Another variation, called foil twisted pairs, features no insulation but relies solely on the foil for shielding.

A final option is solid shielding. This rigid or semirigid metal tube is made of copper or aluminum and surrounds the insulated conductor. It offers 100 percent protection from EMI. Larger cables may incorporate corrugated-like tubing.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!