Workstations: Drawers vs. Shelving

Tysinger Motor Co. uses drawer storage to conveniently hold irregularly shaped items. Photo courtesy Lista International

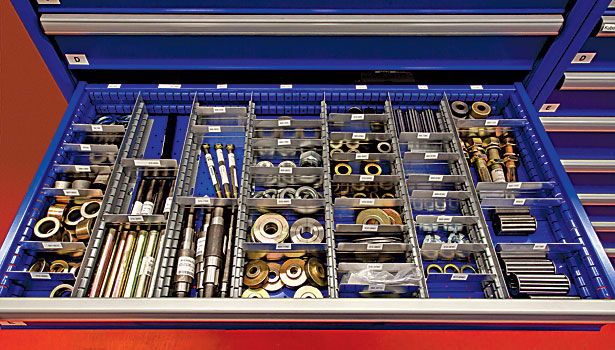

Drawers can ideally organize and store small parts and tools. Photo courtesy Lista International

High-density storage cabinets helped equipment dealer Ahearn save valuable floor space in its parts department. Photo courtesy Lista International

Drawer storage units can play a key role in 5S initiatives. Photo courtesy Lista International

Shelving units can divide a room into a series of dark, uninviting corridors. Drawer cabinets allow for a better-lit storage area and improved ventilation. Photo courtesy Lista International

Drawer storage doesn’t necessarily have to be located off by itself. Drawers can also be integrated into workstations. Photo courtesy Lista International

Many factors come into play when selecting storage equipment, but one important decision is whether to opt for drawer storage cabinets or traditional industrial shelving. While bulky items are well-served by standard industrial shelves, in most situations the best option is high-density drawer storage cabinets. This type of storage makes the best use of every square inch of valuable square footage, improves safety and ergonomics, facilitates inventory management, and is more aesthetically appealing.

Not all drawers are made alike, however. The best high-density drawers make the most use of full cubic capacity while providing easy, direct access to tools, parts and other stored items. Be sure to look for drawers with full-height sidewalls and full-extension capabilities, so the entire three-dimensional drawer space can be used—front-to-back, side-to-side, and top-to-bottom. The drawers should be able to handle a lot of weight, even at 100 percent full extension. Some cabinets have drawers that can carry 440 pounds.

Giving each part a “home” is essential for efficiency. Drawers that are easily subdivided into compartments allow separation of individual parts. The most preferable drawer dividers allow easy identification of compartment contents, including bar code labeling.

Other useful features in drawers include:

- Partitioning slots on all four sides, enabling flexible subdivision for better item organization and faster retrieval.

- Convenient drawer dividers with angled top edges to allow fast, accurate identification of compartment contents and accommodate most bar code labels.

- Drawer handles that are flush with the cabinet housing when closed so nothing protrudes, improving safety and appearance and allowing easy access and passage without snagging clothing.

- A good locking system for secure, safe storage.

- The ability to integrate an inventory management system with the drawer storage, so items are easy to find, pick, replenish and track.

Better Lighting and Aesthetics

Rows of shelving units can divide a room into a series of dark, uninviting corridors, blocking out light and inhibiting airflow. Drawer cabinets are much more attractive, keeping stored items out of sight until the drawer is open. In addition, their dimensions allow for a much better-lit storage area and improved ventilation. Better lighting and improved aesthetics can do wonders for a company’s professional image, and can also boost employee morale, creating a safe, pleasant and productivity-enhancing workspace.

Most facilities have limitations on the amount of space that can be devoted to storage, so facility managers need to make the most of the space available. Drawer storage cabinets are much better at making full use of the available cubic space than shelves, particularly if small-to-medium size items of irregular shape and size are being stored.

Shelving is fine for big, bulky, regularly shaped items—anything larger than a shoebox. For example, stackable rectangular boxes can often be a nice fit for shelf space. But irregularly shaped boxes, or items with irregular surfaces (such as most instruments), usually cannot be easily stacked. Even if they are stacked, cubic space is almost always wasted, because most people do not use the full cubic air space available with shelving. Another factor is that people typically store popular items along the front edge of the shelf, hiding and inhibiting access to items at the back of the shelf.

By contrast, drawer cabinets allow storage in right-height drawers that can be filled to the top, using all available cubic space.

Removing fixed shelves spaced 10 to 15 inches apart saves a considerable amount of air. One rule of thumb is that three to five sections of shelving (about 9 to 15 linear feet) can be condensed down to a single eye-level cabinet measuring about 28 inches by 28 inches. Another way of looking at it is that shelving 18 inches deep and 84 inches tall uses no more than 50 percent of its capacity, and sometimes as low as 30 percent. Using the complete cubic storage capacity of each drawer ensures that the correct size parts are stored in the correct sized drawers.

Full use of cubic space with high-density modular drawer storage maximizes overall available floor space. That’s a great benefit, considering what companies might be paying for every square foot of storage space. Space equals money, and switching to drawer cabinet storage can reduce needed square footage by 100 to 400 percent.

For example, Tysinger Motor Co. of Hampton, Virginia, used high-density parts storage provided by Lista International, a Stanley Black & Decker company, to lop off about 5,000 square feet in its parts department area, bringing construction costs for a new addition down to an acceptable level. To make the new facility work, Lista spent more than a week inventorying the parts on hand so they could accurately lay out the new facility with cabinets of the proper height, drawer depth, and size.

While the original goal of installing high-density storage was to be able to carry more parts in a smaller building footprint, an additional benefit turned out to be increased productivity with the same manpower, due to faster part retrieval time.

Safety and Efficiency

With easily customizable compartments, drawer interiors are ideally suited for storing small loose items like nuts, bolts, washers, spark plugs, electrical components and small instruments. These drawer compartments protect the items stored within them, can precisely match stored items by height, width and depth, are easily labeled with bar codes, and provide direct access and viewing.

Compare that to the industry standard way of storing these smaller items on shelves using bins, plastic boxes, or cardboard boxes. Considering how inefficiently they work, plastic boxes and bins are relatively expensive. Ten or 20 boxes can equal the cost of the shelving unit itself, doubling storage equipment costs.

The boxes and bins are also impractical in terms of seeing and gaining access to the items you’re storing. The standard industrial shelf is typically 87 inches high. The top one or two shelves are typically above the head of a standing individual. Seeing what is stored in the upper shelves is impossible without a ladder, and accessing the items is at best difficult, and at worst, dangerous. A half-opened cardboard box can easily spill its contents from a precarious upper shelf.

There are distinct ergonomic advantages for employees working with modular drawer storage. Just as there is no reaching high for items on upper shelves, access to items stored near the floor is also much improved. When items are stored on the bottom shelf of a shelving unit, employees can find themselves on their hands and knees, awkwardly reaching for items and potentially straining backs and shoulders. With full extension drawers, all items in all drawers are within easy reach.

When your inventory is spread out right in front of you, as is the case with modular drawer storage, inventorying items becomes a much easier and more accurate task. On shelves, items will get moved around and shifted from their originally assigned homes. Items are much more likely to get lost on shelves, which leads to wasted inventory and stock-outs. Within a highly organized modular drawer, each individual item has its own compartment and items are much less likely to get lost or misidentified. Because items can be viewed from the front of the drawer to the farthest back corners, visual accounting is easy, and order picking takes much less time.

For added organization and easier inventory management, some manufacturers’ drawers have built-in label holders. Each compartment can be labeled with stock-keeping units, text, illustrations or bar codes. Shelving usually does not provide for this type of efficient parts location system.

Take the example of Ahearn Equipment Inc., a busy outdoor equipment dealership located in central Massachusetts. The company had tripled in size and simply run out of space to stock the inventory it needed to support the increasing number of lines it carried. In addition to being cramped for space, the existing storage system was inefficient and unorganized.

“We frequently were losing parts that would fall out of the bins or were oddly sized and would not fit well into the bins,” says Jeremy Ahearn, general manager of the dealership. The shelves were 36 inches wide by 12 inches deep and spaced about 12 inches apart vertically, leaving a tremendous amount of space between the top of the bin and the shelf above it.

Seeking to reduce the square footage of the parts department, Ahearn also wanted to find parts more efficiently and reduce lost sales due to missing parts. “We had been plagued by the fact that a customer would come in, our inventory system would indicate that we had a particular part, but we couldn’t find it when we went in the back to look,” says Ahearn. “It may have fallen out of one bin and ended up in a different one, and we really wanted to eliminate this issue.”

The company opted to replace 300 existing storage shelves with 14 new high-density drawer storage units, which reduced the parts department footprint by 50 percent while increasing the number of parts stored. The freed-up space allowed Ahearn to expand showroom space to accommodate its expanding inventory, without adding new buildings.

Improved Security

Modular drawer storage cabinets protect valuable tools, parts and other assets from environmental wear and tear. Items come out of the drawer looking as clean as when they went in. This is far from the case with shelving. Items left out in the open collect coatings of dirt, dust and grime.

Drawer storage can also provide much greater security for valuable items. Whereas shelving is by nature open and unlockable, cabinets are available with a range of locking options. Even within a locked storage room, additional locking systems on drawers can improve security and reduce shrinkage.

From space and cost savings to security, inventory control, lighting and aesthetics, drawer storage cabinets are the more efficient and productive option for storing small and medium sized items.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!