Functional Testing Moves Upstream

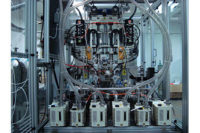

State-of-the-art sensors and feedback technology allow engineers to monitor and control the assembly process. Illustration courtesy Promess Inc.

It is now possible to track individual components and assemblies through the entire manufacturing process, which improves product quality. Photo courtesy Kistler Instrument Corp.

Increasing demand for turbochargers has generated a spike in functional testing in the auto industry. Photo courtesy Napier Turbochargers Ltd.

This turbocharger test system incorporates multiple tests into one cell, including leak testing, flow testing and vibration analysis. Photo courtesy Cincinnati Test Systems

On this axle spin test station, the drive rotates the differential in both directions at 500 RPM, while the test system performs torque and vibration evaluations. Photo courtesy Sciemetric Instruments Inc.

Functional testing traditionally occurs at the end of an assembly line, before products are packaged and shipped. Today, new tools allow manufacturers of mechanical and electromechanical assemblies to conduct in-process testing and verification.

A growing number of automated assembly lines are incorporating technology that allows engineers to know if a product works the way that it was intended. That enables them to improve product quality and enhance process uptime.

Vision systems can tell engineers if all the parts are present in an assembly. Leak detectors can tell you if a part is gas-tight or water-tight. However, functional testing involves challenging the performance of an assembly against a set of predefined performance criteria.

“Assembling to a functional requirement means directly measuring the functionality of the part during the assembly operation and using this information to control the process,” says Glenn Nausley, president of Promess Inc. “It allows you to know that every assembly will function correctly as soon as it comes off the line.”

State-of-the-art sensors and feedback technology let engineers monitor and control an entire assembly process. By using servo-controlled mechanics, along with a closed-loop control system, they can measure functional characteristics in-process and use that feedback to make real-time adjustments to an assembly.

“The availability of precise motion control and more advanced sensor data collection and analysis technology has [revolutionized functional testing],” explains Nausley. “New technologies have opened the door for testing of individual components at a higher level than was possible in the past.

“End user expectation of quality and product feel has also been a driving force behind the growth in function testing,” adds Nausley. “Many years ago, no one would complain if a knob [on a dashboard] turned a little rough or a switch had a heavy click to it. Now, customers expect smooth, ‘nice feeling’ operation of every aspect of a vehicle, from the light switches and sun visor to the steering wheel and pedals.”

“Functional testing is required in every industry, from consumer electronics to medical devices,” notes David Golembiewski, joining systems engineer and key account manager at Kistler Instrument Corp. “By performing a functional end-of-line test on produced products, companies are able to mitigate risk and improve perceived product quality.

“In the age of Big Data, every department wants hard numbers on measured product parameters, from design teams to product release engineers,” Golembiewski points out. “[A] significant change [in recent years] is the expectation and requirement for complete data about every part being manufactured.

“It is now possible to track individual components and assemblies through the entire manufacturing process, which improves product quality and permits isolation of suspect parts,” claims Golembiewski. “In a worst-case scenario, [manufacturers] can now limit the scope of recalls to only isolated batches of product, based on this powerful production data.”

Process traceability systems allow manufacturers to keep more detailed records than ever. “Now, if an engine has a loose hose clamp or is missing an O-ring, engineers have the scientific means to go back and fix it,” says Nathan Sheaff, CEO of Sciemetric Instruments Inc. “It’s not a guessing game anymore. You can go back in time, like a flight recorder.

“Today, manufacturers can collect and store a vast amount of information that’s pertinent to quality and process improvement,” explains Sheaff. “No one worries about data storage anymore, like they did 10 years ago. In addition, software tools make it easy to analyze and display data.”

“High quality of the products [being assembled] is no longer a competitive advantage, but mandatory,” adds Ville Wallenius, product manager at JOT Automation Ltd. “This means that quality must be assured before releasing products to market. Functional testing is one good way to do it.”

Diverse Applications

Functional testers are used to produce medical valves, engine turbochargers, electric motors, thermostats, electronic and mechanical control devices, plumbing fixtures and a wide variety of other products.

Many types of applications can benefit from assembling to a functional requirement. For instance, consumer products where the customer can feel resistance, such a hinges, pliers and steering systems, are good candidates. Products where a standard dimensional measurement is not feasible or will not ensure correct operation, such as ball joints and valves, can also benefit from functional testing technology.

“The automotive and appliance industries are big users,” says Gordon Splete, marketing director at Cincinnati Test Systems (CTS). “The medical industry also conducts simple function testing, such as flow or back pressure measurements, to verify if a part has occlusions to prove that it will flow properly.”

“Function testing is really a very old idea,” claims Nausley. “All industries that make assemblies probably use it in some form or another. What is new is the higher level of testing on individual mechanical components.

“In the old days, it was done on the final assembly,” explains Nausley. “You built a car and you took it for a test drive. Even in aerospace, you would build a plane and some brave guy would take it for a test flight. Technically, this is function testing.

“In the automotive industry, complete engines and transmissions are end-of-line tested and have been for a long time,” Nausley points out. “However, many more type of components and subcomponents are now being functionally tested.”

A wide variety of automotive components are produced with functional testing systems. In addition to engines and transmissions, electronics, seats, safety components and infotainment systems are all functionally tested before reaching a consumer.

Functional testing ensures that fuel injectors control the correct amount of fuel they inject. Fuel, water and power steering pumps are checked to ensure that they work efficiently.

“Engines are spun cold to check for nominal resistances to torque, and for subtle vibrations,” says Golembiewski. “Both serve as indicators of problematic components long before the engine is started as a car rolls off the assembly line.

“Even earlier in the production process, electromechanical servo press systems that assemble engines are able to control and monitor forces and positions of components during the assembly process, and compare them to nominal force and displacement profiles,” explains Golembiewski. “This means that only nominal components pass downstream in the production process, reducing assembly time wasted on imperfect parts.”

“The list is almost endless on what can be tested,” adds Nausley. Promess equipment is used for all kinds of functional testing applications, but the company specializes in anything having to do with torque and force.

“Does it turn, twist or slide?” says Nausley. “Anything and everything that moves is a candidate for function testing, including adjustable steering, floor pedals, power windows, seat mechanisms and sun visors.”

For instance, assembly monitoring equipment is used to test six-way power seat motor systems, using functional relationships such as force and distance. A freeness and effort test moves the seat recliner mechanism through all axes of programmed motion. The test also measures motor current and duty cycle throughout a full range of motion.

Increasing demand for turbochargers has generated a spike in functional testing in the auto industry. In fact, engineers at CTS recently developed a function test system specifically for turbochargers. It uses room-temperature air to charge the turbo instead of hot gases from a combustion engine.

“Cold testing turbochargers increases throughput, because the part is cool enough to handle immediately after test completion,” says Splete. “[Our] test system incorporates multiple tests into one cell, including leak testing, flow testing and vibration analysis.” The system controls oil flow through the hydraulic bearings, runs the turbo up to a selected speed and collects measurement data, such as speed, pressure, temperature, noise and vibration.

Assembly Line Integration

The shift away from end-of-line testing is allowing manufacturers to reduce the complexity and cost of functional testing, while simultaneously improving quality and throughput. By measuring the functionality of a component as it is being assembled, engineers can also improve process reliability.

“End-of-line testing has gradually been moving upstream,” says Sciemetric’s Sheaff. “The trouble with the traditional ‘build it, then test it’ philosophy is that it isn’t a lean strategy. It doesn’t identify process problems. The goal of functional testing is to make sure you make it right the first time by integrating testing and measurement right inside the assembly process.

“The move away from end-of-line to upstream, in-process testing has been a big trend,” adds Sheaff. “It means the complexity of the functional test can be reduced. You don’t need an expensive, complex apparatus sitting at the end of the line, like in the past. If you test a product little by little at each subassembly stage, by the time it gets to the end of the line, it’s virtually perfect and you can fix any problems faster.”

Instead of spending several million dollars for an end-of-line tester, Sheaff says many auto part suppliers are now buying several $50,000 testers and inserting them at the end of various subassembly stations.

“Traditionally, function testing means end-of-line testing,” adds Promess’s Nausley. “This does not catch a problem until the part is at its most expensive and it is too late to use the data for anything more than recognizing rejects.”

According to Nausley, it’s much better to incorporate functional testing as early in the production process as possible. But, testing the function of subcomponents requires a lot of thought and planning in the early stages of process development.

“This can only be done with management’s push,” warns Nausley. “Management has to give engineers time and financial resources for process development. But, the payoff is big.

“Functional testing is interesting, but more exciting is combining function testing with the assembly station and using the functional data in real time to control the process,” adds Nausley. “This is the ultimate dream of the assembly engineer: to be able to compensate for variability in the subcomponents and make the assembly to its perfect function every time.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!