Does 3D Printing Work with Wiring?

Additive manufacturing can be used to produce connectors and terminals.

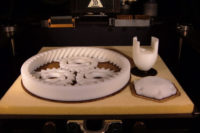

Additive manufacturing “prints” an object from a digital file by depositing one layer of material on top of another. Photo courtesy Stratasys Ltd.

According to many experts, 3D printing promises to revolutionize the way numerous products are designed and mass-produced. Among other things, the technology can be used to create connectors, terminals and other wiring harness components. And, some day not too far down the road, 3D-printed parts may even eliminate the need for traditional wire and cable assemblies.

Additive manufacturing “prints” an object from a digital file by depositing one layer of material on top of another. It allows companies to more easily manufacture complex shapes and structures that have been traditionally been difficult to make with plastic-injection molding and other old-school processes.

While 3D printing holds tremendous promise, it’s not about to be used in mass-production any time soon. That’s because electrical wiring systems are different than other types of products where the technology is being used, such as creating custom jigs and fixtures.

“The systems are more complex in terms of having multiple materials and a need for electrical and mechanical function,” says Gary Fedder, head of the Institute for Complex Engineered Systems at Carnegie Mellon University. “[However, additive manufacturing allows engineers to use] a lower number of components in assemblies, better long-term reliability and on-demand customization.”

“[Creating wire assemblies is] more difficult than current 3D printing applications because of the required flexibility cables offer,” adds Leon Wong, director of PARC Inc., a technology innovation center that has been working with NASA engineers to develop a printable spacecraft, including electrical systems.

“[But], there is certainly interest for these sorts of things from aerospace and automotive manufacturers, due to weight savings—particularly in aerospace,” notes Wong. “[Automakers are intrigued by 3D printing because] they love smoothly integrated components and curved surfaces.”

Delphi, Molex, TE Connectivity and other leading electrical component suppliers are currently using 3D printing for a wide range of prototyping applications. For instance, they’re creating electrical connectors to functionally test new designs.

To speed product testing with usable parts, wiring harness engineers are eager for an alternative process to plastic injection molding. They’re also interested in low-volume applications that allow them to easily produce one-off designs or custom components.

“[Additive manufacturing] looks promising for much of our product portfolio, from all varieties of electrical signal connectors to enclosures,” says Rob Shaddock, executive vice president and chief technology officer at TE Connectivity. “There is still work to be done in terms of increasing the range of plastics that can be used and improving the resolution to create fine details, but there are applications where this technology is suitable today.

“There are already applications where we use this technology, such as connector housings and enclosures.” adds Shaddock. “That includes wiring organizers, patch panel frames and fiber-optic splice trays.”

According to Shaddock, 3D printing technology isn’t advanced enough for most terminal designs. “It could be done and finished with some polishing for larger terminals, but many of our signal terminals are complex designs with fine features,” he explains. “We have other ways of prototyping them.

“For the moment, the most notable benefit is prototyping during the development stage, but we have been using the technology to create tooling,” says Shaddock. “In that application, we can speed up the development of tools, but we can also make tools with integrated cooling [features] that were either impossible or very expensive to make in the past.

“It gives our [engineers] more freedom to experiment with different ideas for our customers,” Shaddock points out. “We do a lot of customer-specific engineering and 3D printing is an important component of that creative process.”

Engineers at Molex have been using 3D printing to create one-of-a-kind assembly aides and fixtures. “This is a very practical use of 3D printing,” claims Harry Etters, vice president of product development for the transportation products business unit of Molex.

“New ideas for these tools can quickly and inexpensively be created to aid in the manufacture of our products,” notes Etters. “The process is inexpensive and prompt. Good designs can be replicated immediately or, if needed, design modification can be readily prepared and tried.

“We are also looking into using 3D printing to create mold tooling inserts,” adds Etters. “Existing mold construction technology is limited in the ability to where and how cooling lines are created. 3D printing allows for the creation of conformal cooling—complex cooling channels within the tool that target cooling into specific hot-spots.”

Etters believes that 3D printing for mass production of electrical components is still in its infancy. “The technology is not yet mature enough to be placed in most applications, primarily because of dimensional or structural performance requirements of our products,” he explains.

Keith Huber, president of Coho Designs LLC, a product development and design consulting firm, is more bullish on the potential of 3D printing for electrical wiring applications. The company was an early adopter of additive manufacturing. Recently, one of its customers needed to encapsulate an electrical connector making it waterproof and pressure capable.

“Compounding the problem, the customer requested a three-day turn around and was unable to spare a sample connector, due to cost and availability,” says Huber. “[In addition], our customer insisted we verify our method of encapsulation. Voids, air-bubbles or imperfections in the encapsulation would negatively impact the connector’s water-proof capability.”

Due to the reduced timeline, Huber and his colleagues turned to 3D printing, using fused deposition modeling (FDM). “It was the only option available that even had a chance of meeting our customer’s expectations,” claims Huber.

With no model available to work with, Coho Designs asked its customer to have the connector laser scanned. Using a CAD model, along with the customer’s design input, a desired overmold shape was created and 3D modeled.

“To overcome the challenge of encapsulation verification, we decided to use the laser-scanned model of the connector to 3D print a copy for encapsulation, as if it were the real connector assembly,” says Huber. “The 3D-printed tools were used to create left- and right-hand silicon molds.”

In addition to silicon molds, other FDM parts were designed to hold the connectors and silicon molds stationary during the potting process. These parts, which were also 3D printed, were designed to be held together with fasteners and threaded inserts.

“I believe the use of 3D printing will only expand in the future for similar applications, due to ever shortening design cycles, budgets and delivered product quantities,” says Huber. “If you think about it, 3D printing a wire harness should be less technical challenging than printing human tissue or body parts, and that capability already exists.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!