|

|

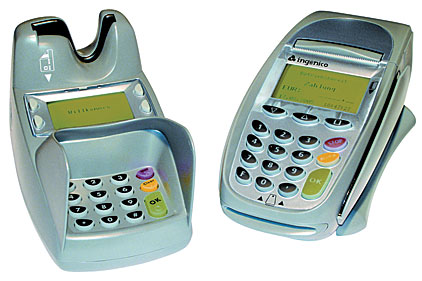

A PIN pad terminal without a shroud (right) offers no protection from attempts to observe someone’s PIN. Photo courtesy Fabrico

|

Ingenico is the leading manufacturer of PIN pad terminals, with more than 15 million deployed in 125 countries. The company’s terminals are used worldwide in medical offices, restaurants, stores, gas stations, banks and vending machines.

The terminals support RSA, DES, and 3DES encryption standards to ensure data integrity. They also incorporate a 32-bit processing architecture that quickly processes powerful cryptographic algorithms.

Recently, regulatory agencies required Ingenico to create a privacy shroud for all PIN pad terminals. The shroud provides merchants and consumers with an additional security measure to reduce fraud and identity theft.

Engineers at Ingenico designed a shroud and were confident it was strong enough to withstand the abuse of consumer and merchant handling. They turned to materials and adhesive supplier Fabrico to find the best adhesive to securely bond the shroud to the terminal.

Fabrico selected VHB 5925 tape, made by 3M Corp., because it offers high performance characteristics, moisture and chemical resistance, and durability. It also has a nice appearance. Equally important, it allows easy retrofit of the shroud to existing terminals.

A modified acrylic foam tape, VHB 5925 is viscoelastic—meaning the foam has energy-absorbing and

stress-relaxing properties. The tape’s acrylic chemistry provides excellent durability when bonded to plastics having medium to low surface energy.

The tape provides a high level of conformability while maintaining high internal strength. It is double-coated and pressure-sensitive with closed-cell construction. The tape is 0.025-inch thick with a tolerance of ±15 percent.

|

|

The shroud is adhered to the PIN pad terminal

with VHB 5925 tape made by 3M Corp. VHB 5925 is a double-coated modified acrylic foam tape. Photo courtesy Fabrico

|

Peel adhesion is 17 pounds per inch width. Dynamic shear is 90 pounds per inch, and static shear at 72 F is 1,500 grams per 0.5 square inch. The tape’s effective temperature range is -31 F to 194 F, making it suitable for many interior and exterior bonding applications.

In the field, a pair of die-cut tape sections are adhered to the bottom of the shroud, and the shroud is adhered to the terminal.

Over the past several months, more than 100,000 tape-section pairs have been use to retrofit thousands of terminals. To maximize production, Ingenico redesigned its die-cut tool to use multiple dies. This has enabled Ingenico to cost-effectively install the shroud on assembled terminals not yet

installed and terminals being

assembled.

For more information on materials and adhesives, call 800-351-8273 or visit www.fabrico.com.