|

|

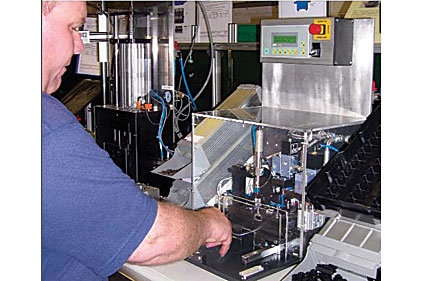

During production, each steering column

module is placed in a sliding fixture and moved to the metering position where thecorrect amount of grease is automatically dispensed. Photo courtesy DOPAG (UK) Ltd.

|

Electromechanical products made by the Group’s Automobile Electrical Division include steering column switches for compact cars and steering column modules for premium class vehicles.

Steering columns are complex assemblies with many moving parts such as mechanical switches to operate direction indicators and windscreen wipers. Electronic components include cruise control switches, gear selector systems, rotary couplers and steering angle sensors.

Rotary couplers transfer electrical signals for the steering wheel air bag and also issue signals via LIN for control functions located on the steering wheel. Coupler options include electrically powered steering wheel heating and a vibration motor to warn the driver if the vehicle begins to stray from the driving lane.

The steering angle sensors are used for active driver safety systems, sleep detection and parking aids. They are low-cost, offer incremental measurement and have up to 0.1 degree resolution.

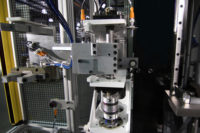

Many of the moving parts in the column module must be greased prior to assembly. These parts require small, but accurately metered, shots of grease. To ensure accuracy, Kostal uses a metering system from DOPAG (UK) Ltd. featuring a P10 or P30 drum pump and chamber-type metering valves.

During production, the part is placed in a sliding fixture and moved to the metering position where the correct amount of grease is automatically dispensed. The pump feeds the grease under precise pressure to the metering valve, which measures and dispenses grease onto the part. For parts that require multiple shots of grease, Kostal uses a metering system with one pump but several metering valves.

The chamber-type metering valves are pneumatically or electrically actuated and handle shot volumes from 0.001 milliliter to 100 milliliters. Progressively adjustable, the valves have a viscosity range from 100 to 1 million millipascal seconds (mPa-s) and can be pressure resistant up to 150 or 250 bar.

The P10 and P30 pumps feed single-component media with viscosity levels up to 5 million mPa-s directly from original containers. Modular and robust, the pumps can be used as central supply systems or to supply single workstations.

The P10 has a flow rate of 290 milliliters per minute and a pressure ratio of 11-to-1 to 37-to-1. Maximum viscosity is 200 to 800,000 mPa-s, and maximum working pressure is 160 to 250 bar. The pump can be equipped with a container that is 86 to 265 millimeters in diameter and features a cartridge 40 to 48 millimeters in diameter.

The P30 has a flow rate of 640 milliliters per minute and a pressure ratio of 33-to-1. Maximum viscosity is 2.5 million mPa-s, and maximum working pressure is 250 bar. The pump can be equipped with a container that is 275 to 400 millimeters in diameter.

For more information on metering systems, call 513-881-6370 or visit www.dopag.com.