Pull production is a basic tenet of lean manufacturing. In a pull environment, downstream activities, such as assembly, signal their needs to upstream activities, such as material handling. The same principles apply to a lean workstation; operators pull parts and access assembly tools when and where they need them on a just-in-time basis.

At first glance, lean workstations may appear to be similar to traditional workstations, but they are inherently different. For instance, lean workstations must be designed for minimal wasted motion, which refers to any unnecessary time and effort required to assemble a product. Excessive twists or turns, uncomfortable reaches or pickups, and unnecessary walking all contribute to wasted motion.

"With a lean workstation, everything must be choreographed like an orchestra, so that every movement has a purpose," says Rick Harris, president of Harris Lean Systems Inc. "It requires a new way of thinking. Traditionally, most workstations were laid out for the material handler's convenience, not for the value-adding operator."

Lean workstations should focus on critical operator issues and concerns, such as safety, ergonomics, getting parts efficiently and finding tools quickly. A lean workstation puts all the assembly materials required at the operator's fingertips. They are strategically positioned so assemblers can reach for tools or parts without even looking.

In addition, a lean workstation must be takt time-centered. Takt time is a common lean manufacturing term that refers to a reference number that is used to match the rate of production to the rate at which customers require finished units. Takt time is determined by dividing the total available production time per shift by the customer demand per shift.

"A lean workstation is a work area that is set up to perform a task that has been deemed an essential step in the manufacturing process," says John O'Kelly, president of Newcastle Systems. "It must be comfortable for the operator, and include the tools and supplies necessary to complete the current task safely, while integrated into the manufacturing process. Workstations can function independently and be lean, but some of the effort is lost if the other workstations, processes and facility layout are not in sync."

In a traditional workstation, parts and tools are spread out horizontally across the work surface. "There's not a lot of thought put into it," explains Eric Dotson, former vice president and general manager of Treston Inc. "However, a lean workstation has more vertical presentation, so tools and parts are closer to the operator. This reduces space and wasted time spent looking for materials."

"Workstations achieve various degrees of lean depending on how they support the principles of lean manufacturing through their inherent design," adds Ray Gottsleben, president of Working Space. "Typically, workstations that are broadly adaptable to changing tasks, can be reconfigured quickly, and can help achieve maximum agility through unlimited layout possibilities are the leanest workstations."

Most experts consider Toyota Motor Corp. to be the benchmark for all lean manufacturing efforts. According to Art Smalley, president of the Art of Lean Inc., Toyota engineers strive to create workstations that follow standardized work and are flexible.

Four preconditions and three pure work elements are necessary to achieve standardized work, says Smalley, a former Toyota engineer. The four preconditions are:

- The workstation must adhere to all safety regulations.

- The process uptime must he high.

- The incoming and outgoing quality of products must be secure and confirmed to build quality into the process.

- The work pattern must be cyclical and repeatable.

The three pure work elements are:

- Design the operator work load close to takt time.

- Designate and maintain only the correct amount of work-in-process inventory.

- Create workstations where the easiest thing to do is follow the ideal work sequence.

"Flexible means, ‘Can the work content of the operator be changed as customer demand changes and the mix of the product changes?'" says Smalley. "As volume changes, [you should be able] to change the number of operators in the area in correspondence with this change. In a lean environment, you must always keep flexibility in mind and be ready with A, B and C workstation variants to produce different [items] with minimal changeover times."

Unfortunately, Smalley says workstations sometimes get overlooked when engineers focus on lean manufacturing initiatives. "There are a lot of variations on lean workstations," he points out. "Lean is very subjective. I see huge variations."

Wasted Motion

Eliminating wasted motion is a critical component of any lean manufacturing initiative. Unfortunately, workstations are notorious sources of waste.

According to O'Kelly, the most common wasted motion is reaching. "It has an enormous impact on the productivity at the workstation and can be easily avoided with the correct workstation size, height and configuration," he claims.

"Reaching is a time waster, as no value is added when reaching," adds Gottsleben. "Excessive reaches are probably the most common type of wasted motion and usually the easiest to address. Reaching, combined with standing, stretching or bending, compounds the problem through excess large-muscle usage and additional wasted time."

When muscle strain is coupled with excessive reaches, such as when bending to lift heavy objects or locate tools, then productivity declines further as fatigue mounts during the shift. "Excessive walking is another indicator of a suboptimized workstation," says Gottsleben, "except in cases of cellular manufacturing where an operator circulates between adjacent stations."

Wasted motion in an assembly workstation can vary with the type of production and the associated volume. "In a low-volume, custom-build situation, the typical waste is having to look for tools, parts and information to complete the job," explains Art Smalley. "In high-volume production, the waste is typically related to turns, twists, reaching or walking to get parts."

Quarterman Lee, president of Strategos Inc., believes it may be time for engineers to resurrect the "principles of motion economy." Ralph Barnes, a professor of business administration at the University of California - Los Angeles, codified the principles in the 1930s and they were successfully applied during World War II. In the 1950s, Toyota incorporated motion economy into its famous production system, which forms the foundation of most lean manufacturing efforts today.

"Then, in its fascination with computers, American industry pretty much forgot about motion economy during the 1960s," Lee points out. "When lean manufacturing was re-imported from Japan, motion economy was left behind.

"The principles of motion economy reduce waste at the workstation or micro-level," explains Lee. "They make repetitive tasks easier, more efficient and more effective. They also reduce cumulative trauma, such as tendonitis and carpal tunnel syndrome.

"At first glance, they seem simple, self-evident and merely common sense," adds Lee. "But, if motion economy is common sense, common sense is not very common."

However, Lee warns that motion economy has limitations. For instance, it does not account for physical limitations or differences in operators.

"A movement that appears ineffective from a motion economy perspective actually may prevent fatigue and possible injury from static posture loading," Lee points out. "However, using them alongside principles of ergonomics and a rationalized design procedure will ensure a productive, safe and optimum workstation."

What to Look For

To be truly effective lean tools, manufacturing engineers must devote more time and effort up front before specifying a workstation.

"Most workstations just happen," says Lee. "No one takes much time to design them." When evaluating a workstation, he recommends focusing on specific areas, such as handling of product or materials; tool documentation and parts presentation; and organization and storage.

"It's especially important to analyze the frequency of reach for parts," adds Lee. "The most commonly used parts should always be placed closest to the operator."

Other experts believe that adaptability to changing processes and tasks is most important. "The only certainty is the inevitability of change in the products and the processes and tools used to build them," notes Gottsleben. "Workstations must not be a barrier to change, but a complement and an aid to change.

"Workstations must be easily and affordably adaptable to changing processes and tasks, and of course, easily tailored to the physical attributes and work habits of those using them," argues Gottsleben. "As production tools, the ultimate goal of the workstation is to increase the productivity of the people who use them, while providing ongoing flexibility and agility for the engineers who define the assembly processes."

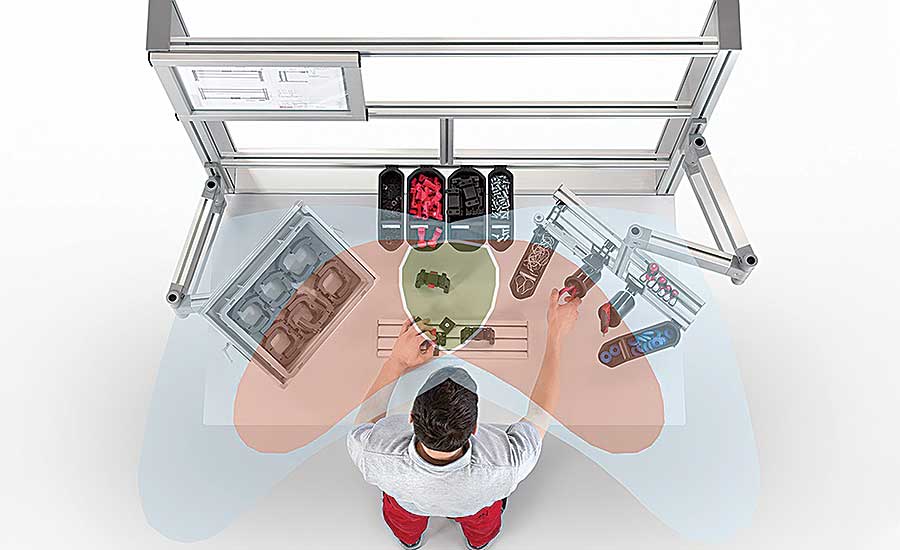

Gottsleben urges manufacturing engineers to become familiar with the basic principles of ergonomics. For example, he says it's important to have an understanding of the three primary ergonomic operating zones: Optimum work zone, optimum grab zone and maximum grab zone.

"Assembly sequence, parts presentation, and organization of tools and equipment should all be considered in light of these three zones," claims Gottsleben. "And [engineers should make] an effort to limit all work to them, with an emphasis on the two optimum zones."

"When designing workstations, it's important to remember that people move in arcs, not straight lines," says Chris McIntyre, vice president of product management at XSensor Technology Corp. "Too many workstations tend to be designed as a rectangular desk. As you move parts and tools further out from the side of the body, they become harder to reach."

Ergonomic reach zones extend both vertically and horizontally. Reaches below shoulder height are less fatiguing. Routinely used tools and parts should be placed within horizontal reach and work zones whenever possible. If reaches become excessive, engineers should consider splitting the assembly operation into two separate tasks.

Engineers should also choose workstations that comply with the principles of lean manufacturing. For instance, engineers should incorporate the 5Ss into every workstation they design.

The Lean Enterprise Institute defines the 5Ss as five related terms, each beginning with an S, that describe workplace practices conducive to visual control and lean production. For example, a 5S approach should be used to label and mark tools. A simple outline of a tool would serve as a visual reference and help ensure easy recognition and quick access.

The 5Ss are based on Japanese words and translated into English as sifting, sorting, sweeping clean, spic and span, and sustain. However, Toyota traditionally refers to just four Ss:

- Sifting-go through everything in the work area, separating and eliminating what isn't needed.

- Sorting-arrange items that are needed in a neat and easy-to-use manner.

- Sweeping clean-clean up the work area, equipment and tools.

- Spic and span-the overall cleanliness and order that result from disciplined practice of the first three Ss.

The fifth S, sustain, is not used at Toyota, because it becomes redundant under the company's system of daily, weekly and monthly audits to check standardized work.

Smalley says Toyota emphasizes safety first, quality assurance second, and standardized work third. When planning an assembly operation, Toyota engineers fill out detailed forms to think through the motions that the operator must perform. "It is a reality-based check system that is very rigorous, but it leads to safe, repeatable assembly processes," notes Smalley.

"When I ask an operator ‘What makes for a good day?' the typical answer I get is: ‘My machine ran fine today; I had the parts I needed on time; and I had no quality problems,'" adds Smalley. "Toyota [makes sure that happens through] standardized work and by creating a safe, repeatable work pattern balanced close to takt time. When people can find a rhythm without disruption, then the day goes by quicker, and quality and productivity tend to be better."

Operator Concerns

Observing the operator at work is an important part of the workstation selection process. "They know better than anyone how products are made and processed," says O'Kelly. He suggests asking operators a series of questions, such as: What are your pains or annoyances? How does the workstation fit within the facility environment? What happens before and after the product arrives at the workstation? What do you want to change about the work area? What do you like about it?

"These factors affect the workstation size, shape, accessory choice and placement, and whether it should be mobile or stationary," says O'Kelly. "Document the different tasks that need to be performed at the workstation and the accessories that may be able to provide relief. Use the information from the operator to find modular workstations that provide variety in surfaces, configurations or sizes, such as height, depth and width."

For instance, O'Kelly says engineers can add adjustable components, such as articulating arms, that allow tools to be moved within the operator's optimal work zone. "Height-adjustable worktables are the best way to address multi-user workspaces," he points out. "Using a crank handle or electric push-button, operators can adjust the height of the work surface easily. These factors contribute to a lean workstation, eliminating unnecessary motion and increasing operator productivity."

According to Gottsleben, addressing ergonomic issues as part of the assembly workstation design process will avoid many long-term costs. "Operators need to feel that they have some control over their immediate work environment and can adjust the workstation to suit them best without compromising the assembly process," he points out.

But, manufacturing engineers should do more than just watch people do a task. "Engineers need to step in and do the task to get a better perspective," says McIntyre. "Try it yourself. Try working at the workstations you design. Ask questions such as: How much force do I have to use? What position do I have to use?"

"Most engineers talk to the operator, but don't actually sit down and do the work," adds Ken McCormick, flow cell product manager at Unex Manufacturing Inc.

"Many engineers also fail to do a mockup of the workstation, using cardboard, styrofoam and PVC pipe," says Harris. "We always invite the operator in during this simulation. He becomes the king. We put him in his work envelope and let him evaluate it."

Parts vs. Tools

When designing a lean workstation, engineers must determine whether it's more important for operators to be able to get to parts efficiently or to find tools quickly. The answer depends on numerous factors, such as the type of product being assembled.

"Engineers must consider the tradeoffs between parts efficiency vs. finding tools quickly," says Dotson. For some applications, a successful workstation starts with the tools in a central location where they're going to be used. The rest of the workstation can be designed around that, putting parts where they are needed. In other cases, parts are a more important consideration than tools.

"They are both needed to get the job done," explains O'Kelly. "The ideal workstation allows parts and tools to co-exist peacefully." He says workstations can be designed to accommodate all the necessary parts and tools for the workday incorporating modular drawers, shelving, racks and carts.

While parts and tools are equally critical, Harris believes there must be some give and take. "The tools an operator is going to use every cycle should be located the closest," he points out. "Many engineers focus too heavily on tool placement and not enough on the interface with the operator. They fail to get input from the operator."

The parts vs. tools dilemma should be determined by the nature of the work being done. "If it is a parts-intensive task with the need to incorporate many parts having short assembly cycle times, then it's probably more important to have efficient access to parts," notes Gottsleben. "If it is a tool-intensive task, where just a few parts are worked on, but where a number and variety of tools are required to assemble, adjust or calibrate the assembly, then it may be best to focus on tool retrieval.

"In any case, the engineer designing the process should categorize the assembly operation into a ‘parts' or ‘tool' dominant activity, and then optimize the process by placing the most-used items within the optimal grab and work zones," adds Gottsleben.

Volume also affects whether parts or tools are more important for a workstation. Typically, with lower volumes, tool placement becomes more important, especially if there is special tooling required to assemble the product. In high-volume production environments that use standard parts, getting parts to the operator efficiently becomes a more important consideration.

"It depends on the type of product flowing through," concludes Smalley "With low volumes, there is typically more operator motion, such as more walking. Flexibility may be more important to accommodate more product changeover. In a high-volume assembly environment, the operator may rarely move around during a shift."

Principles of Motion Economy:

- The two hands should begin and end their motions at the same time.

- The two hands should not be idle at the same time except during rest periods.

- Motions of the arms should be made in opposite and symmetrical directions and should be made simultaneously.

- Hand motions should be confined to the lowest classification with which it is possible to perform the work satisfactorily.

- Momentum should be employed to assist the worker whenever possible, and it should be minimized if it must be overcome by muscular effort.

- Smooth, continuous motions of the hands are preferable to zigzag motions or straight-line motions involving sudden and sharp changes in direction.

- Ballistic movements are faster, easier and more accurate than restricted or controlled movements.

- Rhythm assists smooth and automatic performance. Arrange the work to permit an easy and natural rhythm.

- There should be a definite and fixed place for all tools and materials.

- Tools, materials and controls should be located close to and directly in front of the operator.

- Gravity feed bins and containers should be used whenever possible.

- Drop deliveries should be used whenever possible.

- Materials and tools should be located to permit the best sequence of motions.

- Relieve hands of work that can be done more advantageously by a jig, fixture or foot-operated device.

- Combine tools whenever possible.

- Pre-position tools and materials.

- Where each finger performs some specific movement, the load should be distributed in accordance with the inherent capacities of the fingers.

- Levers, crossbars and hand wheels should be located in such positions that the operator can manipulate them with the least amount of change in body position and with the greatest mechanical advantage.

Source: Strategos Inc.