Photo Galleries

Lenze Americas Opens Assembly and Logistics Center in Illinois

On September 25, 2012, Lenze Americas held a grand opening at its new mechanical product assembly and logistics center in Glendale Heights, IL. The facility supports electromechanical product manufacturing operations for the Americas region.

Behind the Scenes at Ford's Michigan Assembly Plant

People are the heart and soul of the 2012 Assembly Plant of the Year. This slideshow shows some of the men and women who build three different types of electrified vehicles alongside traditional gas-powered cars on the auto industry’s most flexible assembly line—Ford’s Michigan Assembly Plant in Wayne, MI. Photos courtesy Ford Motor Co.

Presses for Medical Device Assembly

Senior Editor Jim Camillo writes about case histories that explain why medical device manufacturers are using presses to solve diverse assembly challenges.

Accommodating Older Workers

Check out feature images from Assembly's June cover story about the challenges older workers face in the auto industry.

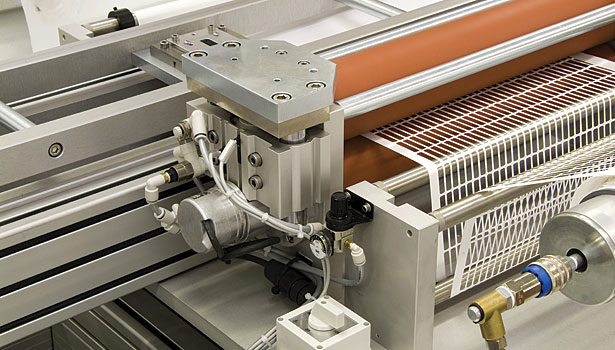

Hot Crimping

In 2010, Strunk Connect Automated Solutions GmbH & CoKG introduced hot crimping after years of improvement. The technology is based on the company’s resistance welding process, which has been used by manufacturers in the automotive, medical and solar industries since 1984. Listed here some images of hot crimping technology.

Wire Harness

AssemTech Inc. is a busy and growing harness assembly shop in West Chicago, IL. The company has a 12,000-square-foot assembly area and employs 20 full-time harness assemblers - far cry from its early days back in 1986, when founder Chuck Hall and various family members assembled harnesses in his garage.

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing