John Sprovieri

John has been with ASSEMBLY magazine since February 1997. John was formerly with a national medical news magazine, and has written for Pathology Today and the Green Bay Press-Gazette. John holds a B.A. in journalism from Northwestern University, Medill School of Journalism.

ARTICLES

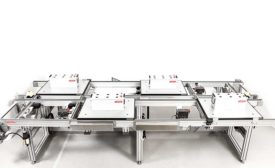

Heavy duty rollers accommodate large and small totes.

Read More

What’s New With Conveyors

Conveyors remain essential for getting parts to the right spot at the right time. Here’s a look at the state of the art.

May 5, 2023

Fastening Tools for EV Assembly

Special fastening tools are need to ensure safety and quality when assembling battery packs for EVs.

May 4, 2023

Assembly With Stainless Steel Screws

Stainless fasteners are ideal for applications that require strength, durability and corrosion resistance.

April 14, 2023

Device Removes Toxic Welding Fumes

A high-vacuum extraction unit integrates directly with the welding torch, instead of operating as a stand-alone device near the weld area.

April 13, 2023

Vision System Inspects Bearing Assemblies

High-speed cameras met cycle time requirement of less than one second.

April 12, 2023

Robots, People Collaborate on Product Assembly

A cobot with a special gripper from the Zimmer Group improves ergonomics and productivity on Weidmüller’s assembly line.

April 11, 2023

Cobots Perform Screwdriving and Packaging for Tool Manufacturing Company

Cobots optimize assembly and packaging by 30 percent.

April 7, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing