Sensing Solutions

sponsored content

Tackling the Most Demanding Applications With Precision Sensors

March 14, 2023

sponsored content

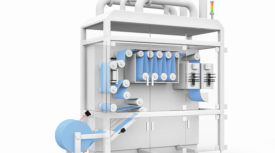

Gain Machine Condition Data with Plug-and-Play System from Balluff

February 13, 2023

sponsored content

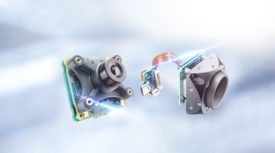

New Balluff Code Reader Offers IO-Link, Condition Monitoring

February 13, 2023

sponsored content

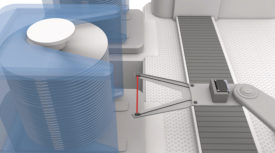

Using Guided Changeover to Reduce Maintenance Costs, Downtime

February 13, 2023

sponsored content

Sensor Selection Suitable for Automation Welding Environments

December 7, 2022

sponsored content

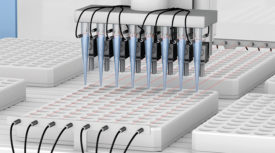

Reducing Assembly Line Mistakes With the Error Proofing Platform Station

December 7, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing