Electrification

New Technology Boosts EV Batteries

Charging Lithium-Ion Cells at Different Rates Boosts Battery Packs

January 4, 2023

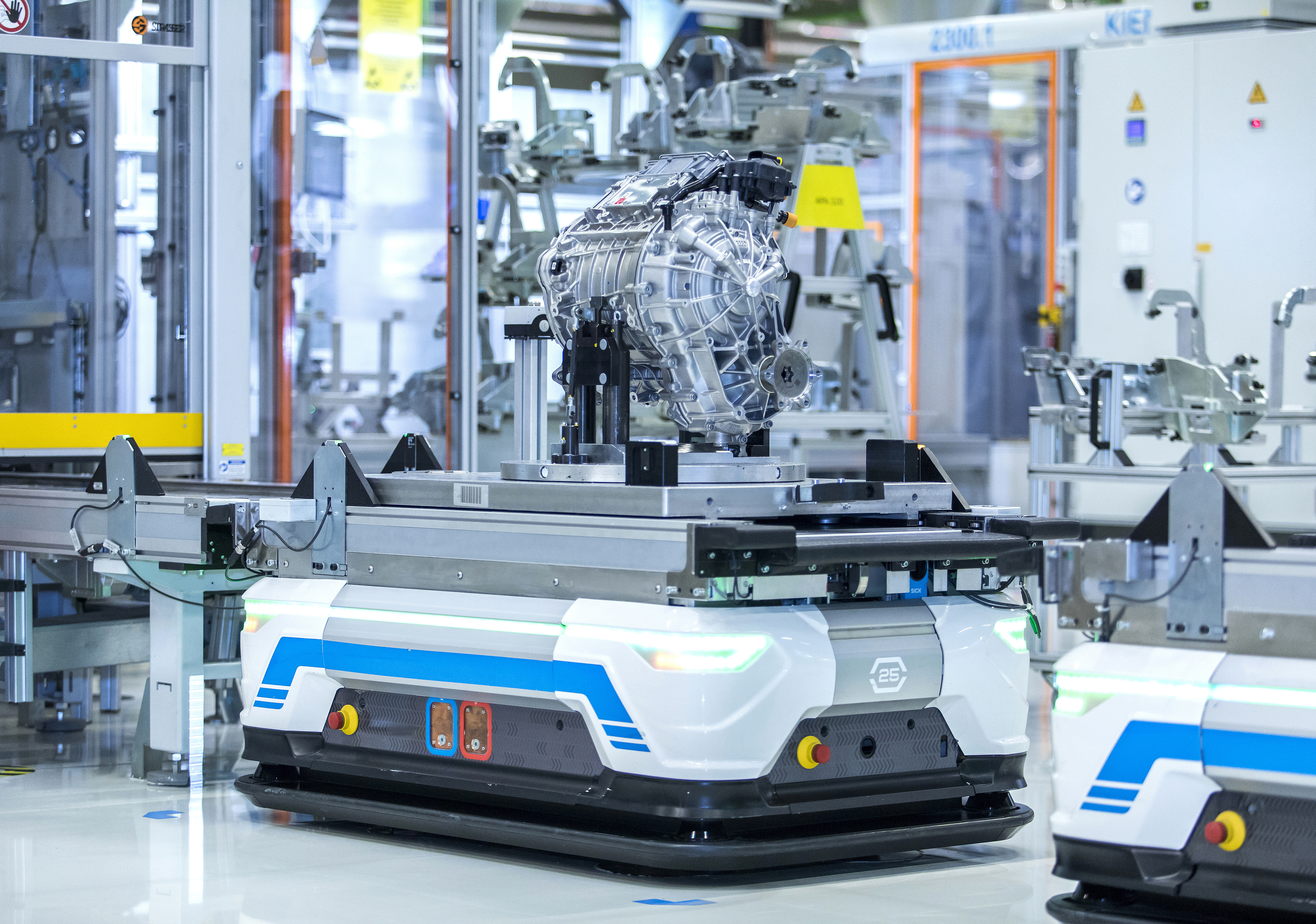

Robots Assemble Electric Vehicles

Automakers need to be flexible and adopt new automation.

December 21, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing