Automotive Assembly

Robots and other tools are key to mass-producing printed parts

Read More

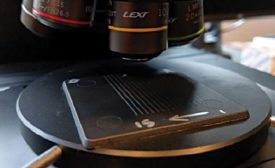

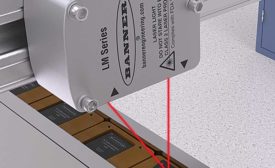

Laser Sensors and Automated Assembly

Very accurate and super fast, these noncontact sensors are ideal for various measurement, inspection and defect-detection applications

June 6, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing