Aerospace Assembly

Robots and other tools are key to mass-producing printed parts

Read More

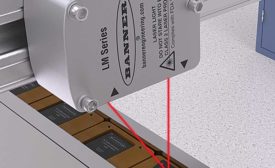

Laser Sensors and Automated Assembly

Very accurate and super fast, these noncontact sensors are ideal for various measurement, inspection and defect-detection applications

June 6, 2019

What’s New With Power Tools

Data collection and ergonomics are driving development of next-gen fastening tools

June 5, 2019

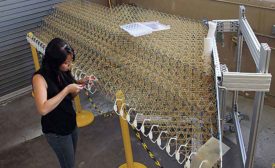

Carbon-Fiber Composites Grow in Popularity

Adhesives and fasteners can be used to assemble many types of composite parts

June 3, 2019

Generative Design Software Is Transforming the Design Process

Aided by cloud computing and artificial intelligence, generative design software is promising to transform the design process

May 13, 2019

IIoT Tech on Assembly Lines

Manufacturers increasingly rely on mobile and stationary technologies to obtain worker- and machine- performance data that optimizes plant productivity

May 8, 2019

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing