Aerospace Assembly

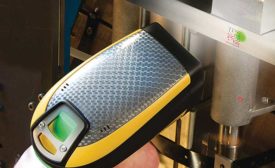

Many assembly operations begin with the scanning of a 1D or 2D bar code.

Read More

Securing Bolted Joints With Threadlockers

Whether pre-applied or applied on the assembly line, threadlockers keep fasteners tight, and immune to vibration and failure

August 4, 2020

Analyzers Aid Automotive Lightweighting Efforts

The adoption of advanced materials is creating challenges for materials analysis and quality control across the automotive supply chain.

July 16, 2020

Health and Safety in Post-Pandemic Manufacturing

A comprehensive approach will ensure safety and productivity.

July 15, 2020

What’s New With Cordless Tools

Today’s industrial-grade cordless tools combine higher torque and greater accuracy with advanced data-gathering capabilities

June 10, 2020

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing