Industries

Accelerated Life Testing

Accelerated life testing helps manufacturers accurately determine how, when and why a product will fail.

July 9, 2021

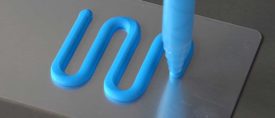

Dispensing Filled Materials

Robust equipment is required to accurately dispense filled adhesives, sealants and encapsulants.

July 7, 2021

New Materials, New Fasteners

As automakers replace steel with lightweight materials, new fasteners will replace conventional screws.

June 11, 2021

Cavity Pressure Is the Key to Molding Consistent, Quality Parts

Pressure conditions in certain phases of the molding process correlate to specific attributes of the part.

June 9, 2021

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing