Industries

Understanding and selecting the right process for plastic part assembly, Part II

Once you’ve had an opportunity to review plastic part assembly and joining options, you can finish out the selection process with some guidelines in mind.

July 1, 2017

Refrigeration Design

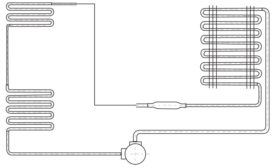

The simplest approach from a refrigeration system design perspective is to use a single evaporator coil.

July 1, 2017

Kitchen Appliances Go Colorful, Matte, and Retro

Learn more about current trends, from colors and textures to touches of nostalgia.

July 1, 2017

Behind the Scenes at DeWALT

DEWALT’s assembly plant in Charlotte, NC, produces high-quality tools while beating overseas competition.

June 7, 2017

Adhesives Aid Truck and Trailer Assembly

High-strength adhesives and sealants can improve the durability and appearance of trailers and truck bodies, while enhancing throughput.

June 7, 2017

Plastic Machine Components Can Boost System Speed

By upgrading gears, cam followers, track rollers and other components, engineers can improve the speed of a machine by 15 to 20 percent or more.

June 7, 2017

Assembling Thermoplastic Composites

Joining thermoplastic composites—either to each other or to other materials—can be challenging.

June 7, 2017

Force and Torque Sensors

Advanced technologies increase the accuracy of force and torque sensors used in product assembly and end-of-line testing.

June 7, 2017

Cordless Fastening Comes of Age

Engineers have more battery-powered options available than ever.

June 7, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing