Home » assembly systems

Articles Tagged with ''assembly systems''

Sponsored Content

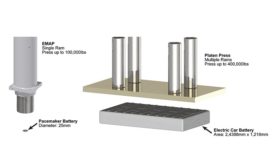

How to Harness Intelligent Manufacturing for Electric Vehicle Revolution

September 1, 2023

Behind the Scenes at Renault’s New Electric Motor Line

Renault has inaugurated a new, highly automated line to assemble EV motors at its historic factory in Cléon, France.

August 7, 2023

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing