Home » SCARA robot

Articles Tagged with ''SCARA robot''

Robotics in the Age of Industry 4.0

Artificial intelligence and data analytics will make robots more productive

May 15, 2020

Robots Strike Right Tone With Guitar Maker

Taylor Guitars relies on robots to help assemble precision electronics for its world-famous acoustic guitars

November 9, 2018

Robots Rule at Automatica

The latest technologies for robotics and automated assembly were on display at the Automatica show in Munich, Germany, in June.

August 7, 2018

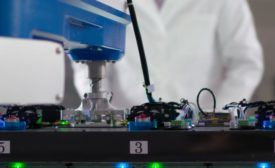

Next-Gen SCARA Robots

State-of-the-art SCARA robots are helping assemblers meet greater demand for speed and precision

April 2, 2018

Robotics

Cartesian, SCARA, Six-Axis and Delta: Robots Wowed Crowds at The ASSEMBLY Show

January 13, 2017

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing