Home » additive manufacturing

Articles Tagged with ''additive manufacturing''

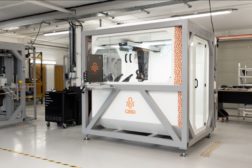

3D Printer Installation onboard USS Bataan

A Conversation on 3D Printing with the CEO of Meltio

June 16, 2023

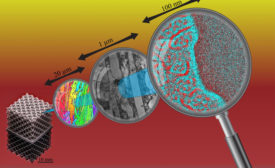

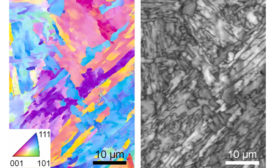

Design for Additive Manufacturing, Part 3

Here are the most common pitfalls when designing parts for additive manufacturing.

December 12, 2022

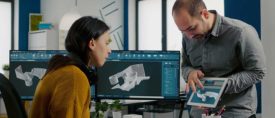

Design for Additive Manufacturing, Part 2

Design for additive manufacturing requires a different approach than that for conventional processes.

November 9, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing